Ultra-thin seam coal mining machine walking system, mounting structure thereof and machine body height position adjusting method

A technology of ultra-thin coal seam and walking system, which is applied in slitting machinery, earthwork drilling, and propulsion, etc. It can solve the problems of scraper machine jamming, small coal passing height, and increased resistance of shearer, etc., and achieves improved adaptability , the effect of low plane height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

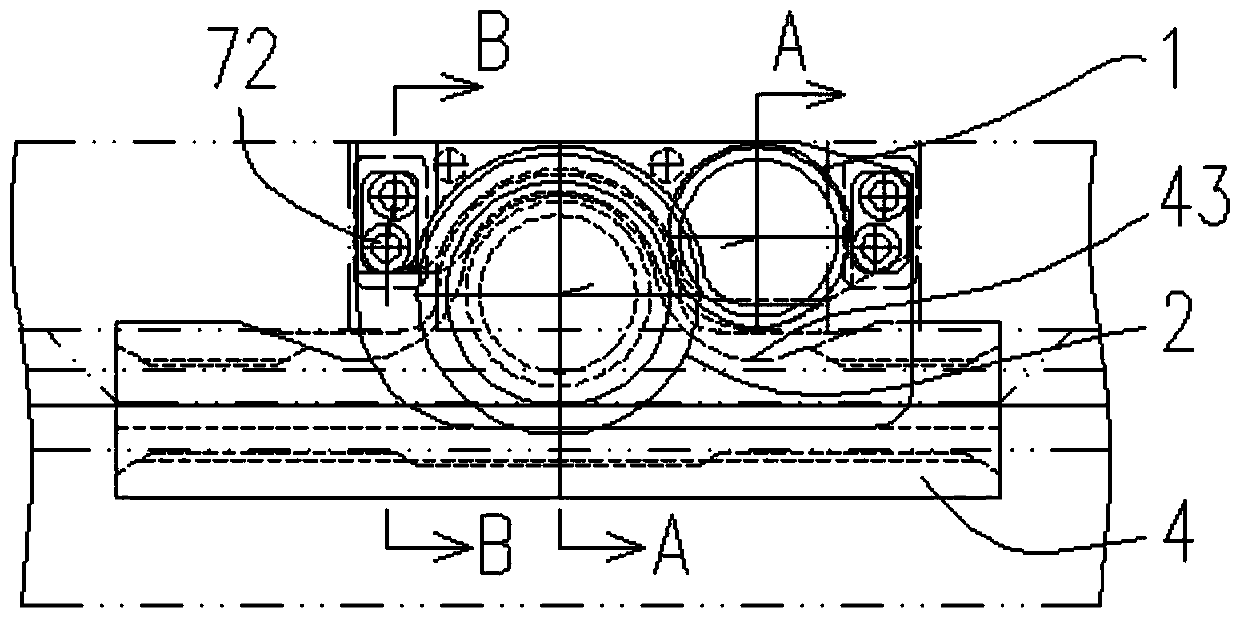

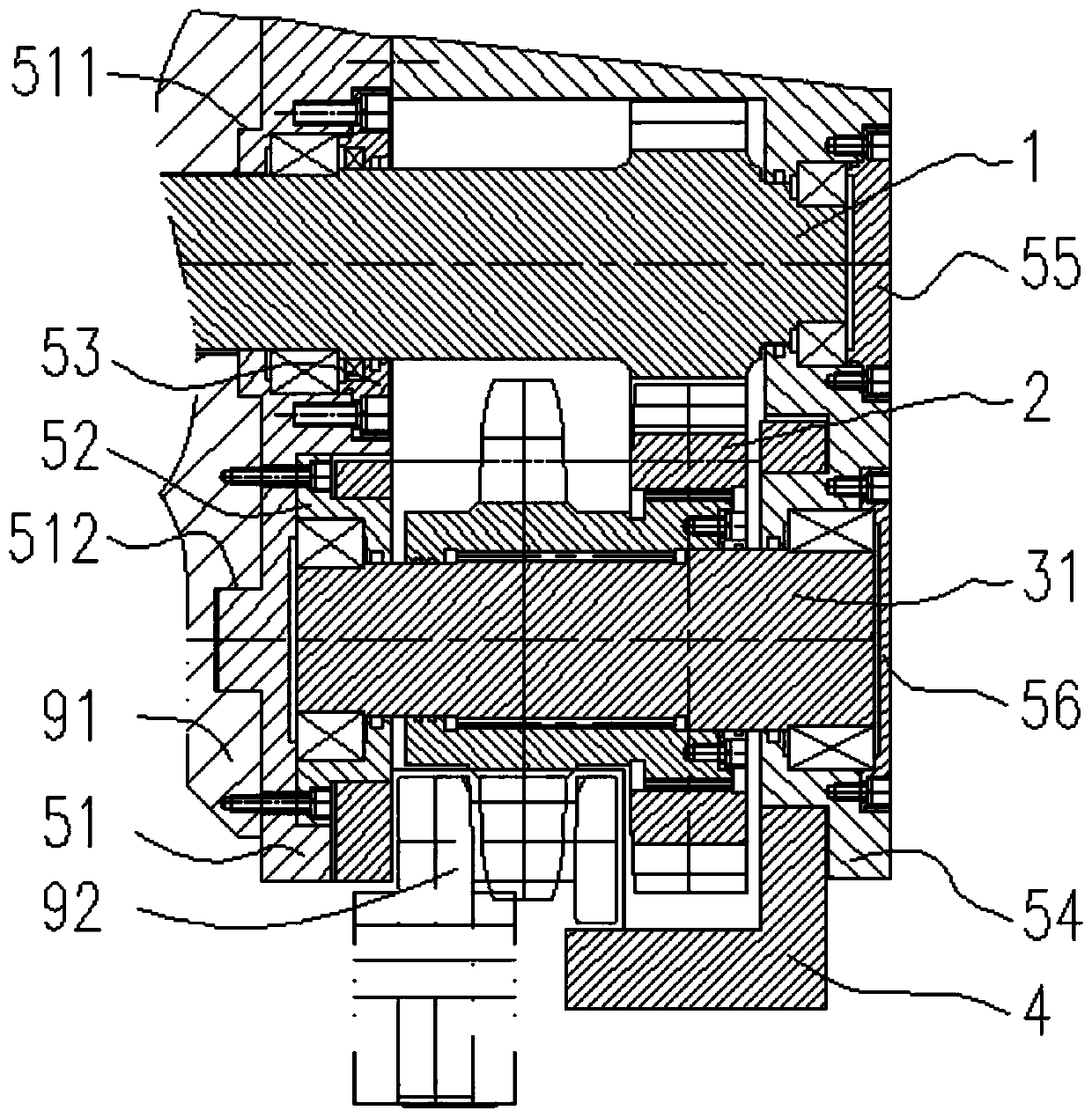

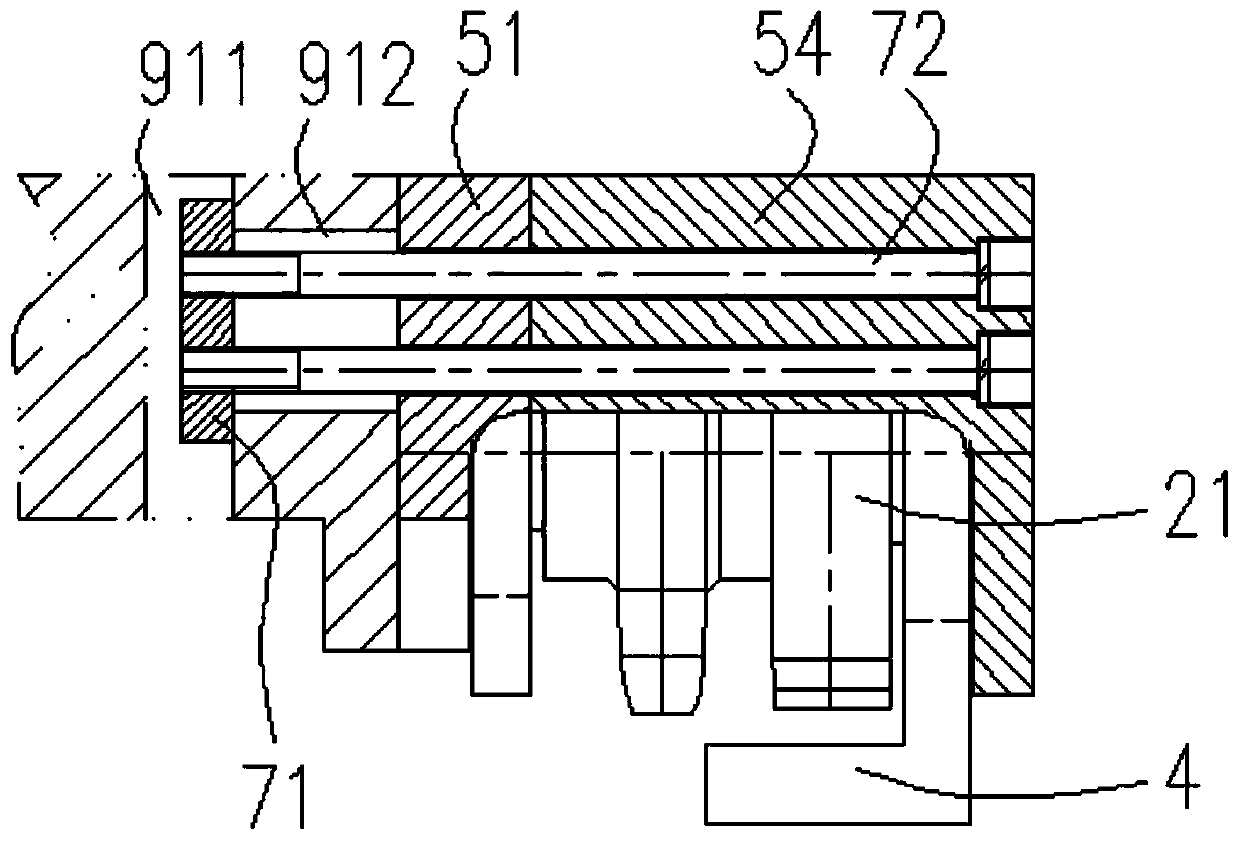

[0057] The invention discloses a walking system of an ultra-thin coal seam shearer, such as Figure 1-23 As shown, it includes a traveling case housing, a driving wheel, a driving wheel shaft, a traveling wheel assembly 2, a traveling wheel shaft 31 and a guide shoe 4, and both the traveling wheel shaft and the driving wheel shaft are rotatably supported on the traveling case housing by bearings on the front and rear side walls. The large gear 21 in the traveling wheel assembly is fixedly connected to the traveling wheel 22 coaxially, and the traveling wheel is coaxially mounted on the traveling wheel shaft. The driving wheel is coaxially fixed on the driving wheel shaft. The bull gear is externally meshed with the drive wheel.

[0058] The guide shoe includes a base 41 and an ear seat 42 located above the base and usually in the middle in the left and right length direction. The base includes a front side wall 411 , a rear side wall 412 and a top plate 413 connected betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com