Underground continuous tunnelling machine

A mining machine and coal mine technology, which is applied in the field of continuous mining machines in coal mines, can solve the problems of high cost, difficult matching of vulnerable parts, and short mine construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

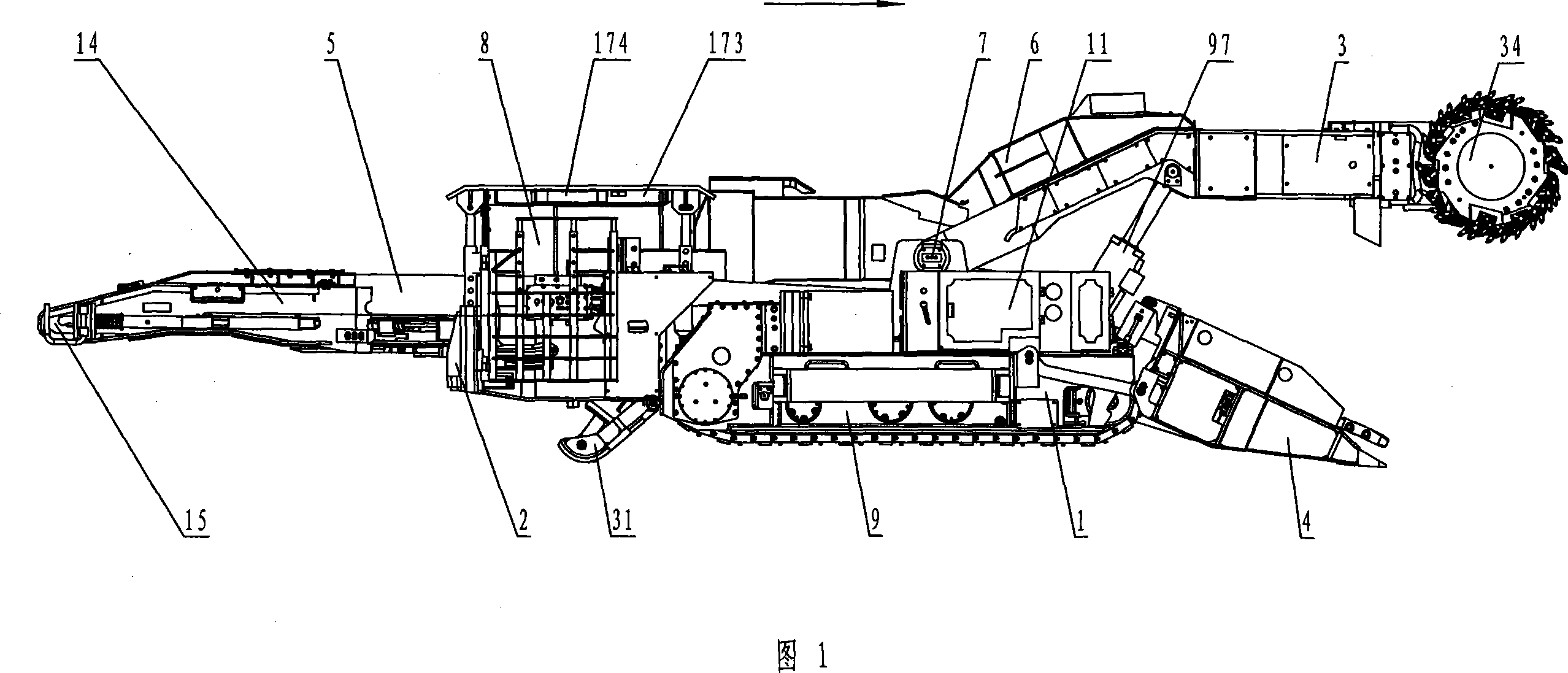

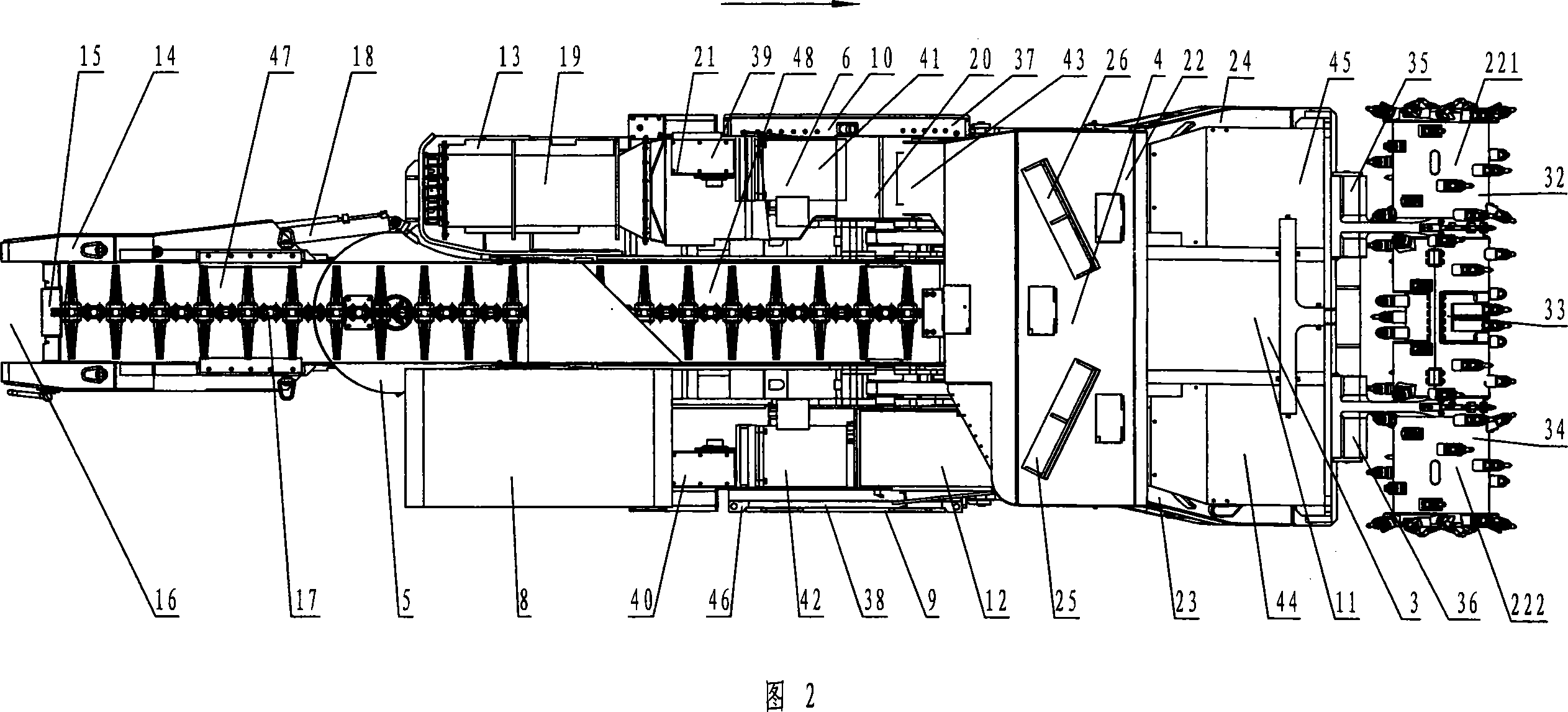

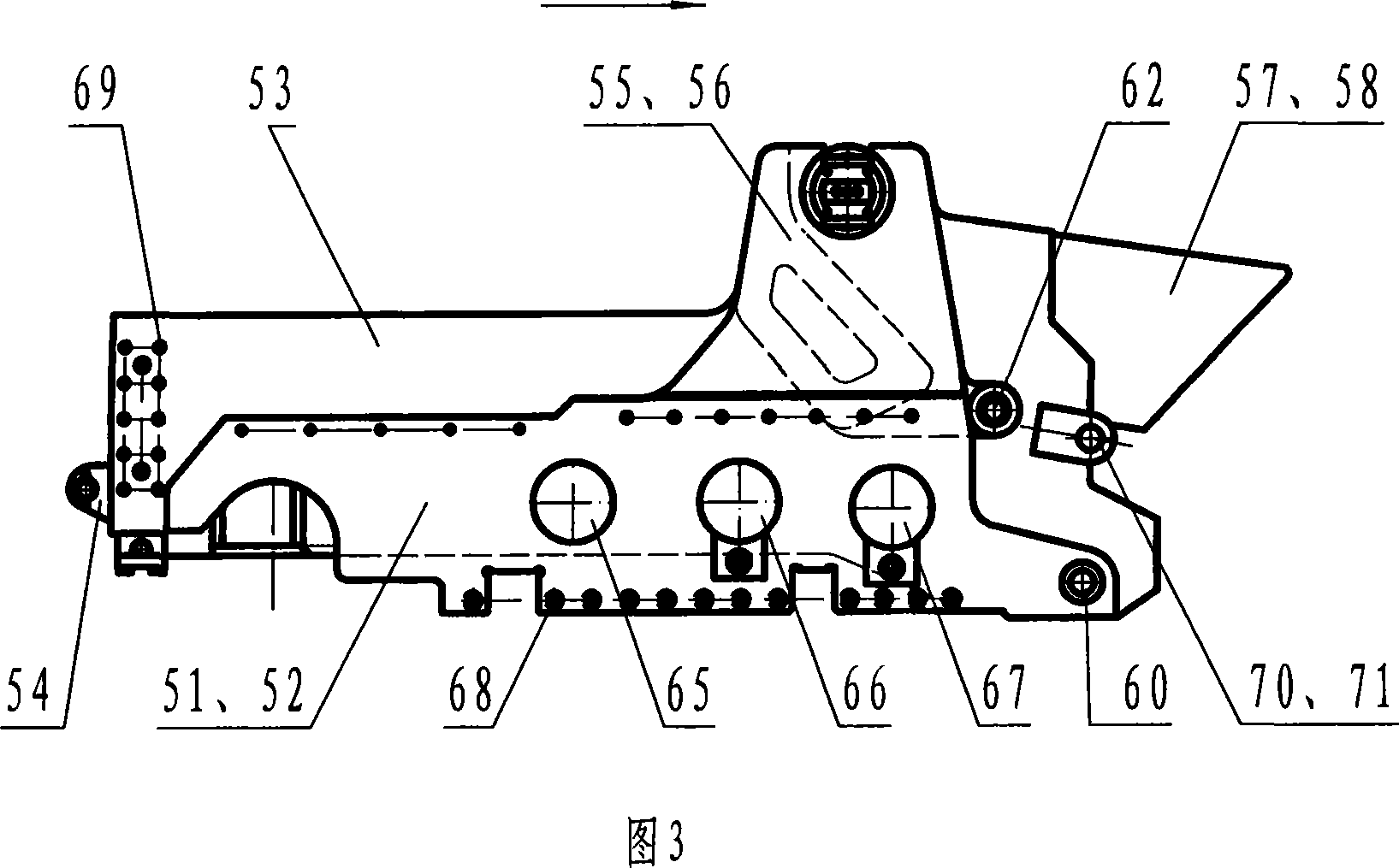

[0047] The present invention will be further described below in conjunction with accompanying drawing:

[0048] As shown in Figures 1 and 2, it is the overall structure diagram. This continuous mining machine adopts 1140V transmission voltage, which is used for the whole machine after being transformed. 8 motors drive each transmission mechanism, and the cutting motors 201 and 202 use torque limiting. 203, 204 torque protection, to prevent damage to the motor during high-power vibration operation, other motors are crawler motor, shovel plate rake claw motor, dust removal ventilation motor, hydraulic oil pump motor.

[0049] The main transmission mechanisms adopt hydraulic cylinders for power transmission. There are tail swing cylinders, swing cable cylinders, cutting cylinders, shovel cylinders, conveying tank cylinders, stabilizing shoe cylinders, etc. The cylinders are powerful and must be coordinated when used.

[0050] Swing engine tail 14, can swing left and right under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com