Tunnel mining machine

A mining machine and roadway technology, applied in the fields of mining excavation equipment and roadway mining machines, can solve the problems of no mining function and complex structure, and achieve the effect of saving working space, high mining efficiency, and ensuring health and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

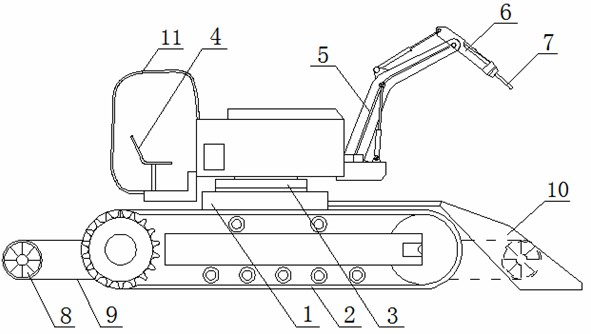

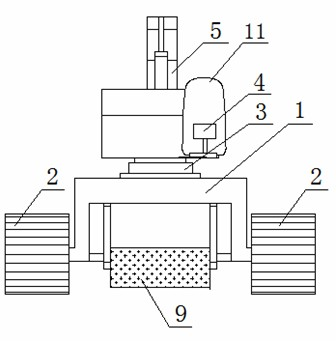

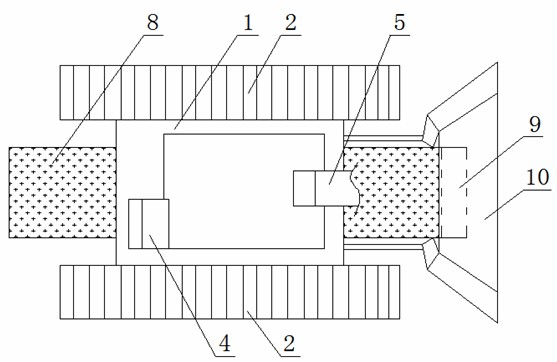

[0025] see Figure 1 to Figure 6 , the present invention is a roadway mining machine proposed by improving the existing crawler excavator, including a chassis 1, a crawler walking mechanism 2, a revolving base 3, a boom 5, a mining mechanism 6 and an operating device, and the revolving base 3 is installed On the chassis 1, the main engine is driven by a power device, which is characterized in that: the power device is an electric motor, and the whole machine is powered externally through a power distribution device, and the bottom of the chassis 1 is provided with an ore conveying channel or at the bottom of the crawler belt traveling mechanism 2 An ore conveying mechanism is arranged above the track.

[0026] figure 1 , figure 2 , image 3 In the above, the chassis 1 is a raised door in the middle, which constitutes the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com