Drum shearer cutting part

A shearer cutting part, drum type technology, applied in cutting machinery, earthwork drilling, slitting machinery and other directions, can solve the problem of difficulty in mining coal seam with gangue, hard coal seam with gangue has a large proportion, overall rigidity and strength Insufficient and other problems, to achieve the effect of wide practicability, strong mining capacity, simple and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the implementation of the present invention will be further described:

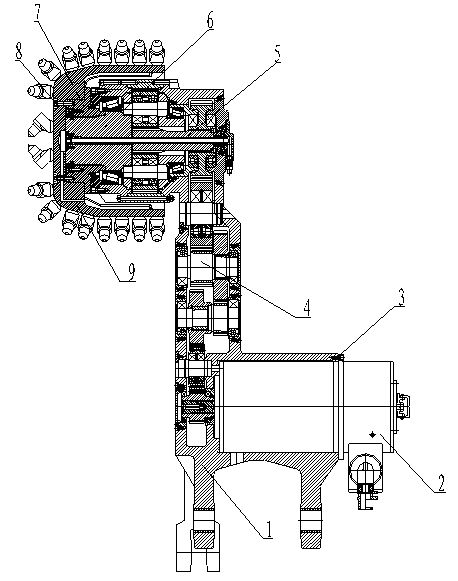

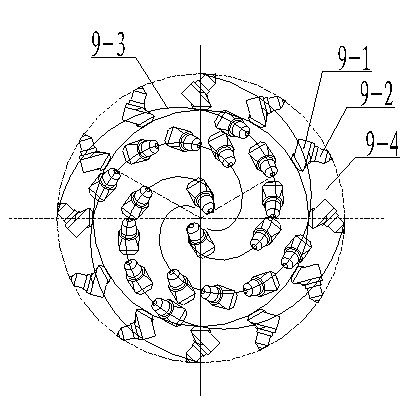

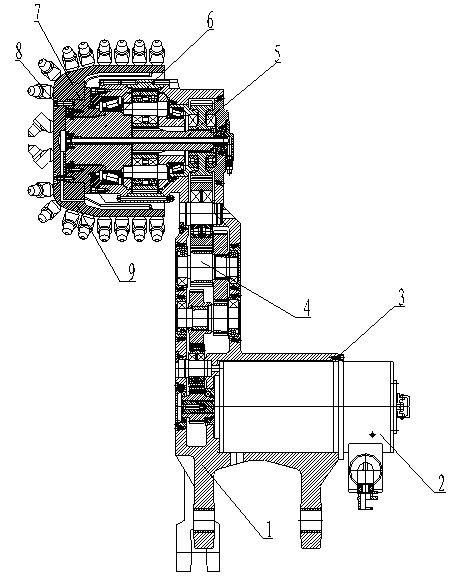

[0011] The cutting part of the drum shearer of the present invention is mainly composed of a rocker housing 1, a cutting motor 2, a rocker reduction box 4, an output shaft 5 of the rocker reduction box, a planetary gear mechanism 6, a square coupling key 7, a cutting Cut drum 9 to form. Wherein: the cutting motor 2 is directly horizontally installed in the rocker housing 1 and fastened by bolts 3 . The output shaft of the cutting motor 2 is used as the input shaft of the rocker gear box 4, and is directly installed horizontally in the rocker shell 1. The cutting motor 2 is connected with the input shaft of the rocker gear box 4. The rocker gear box 4 consists of four stages Cylindrical gear reduction and first-stage idler gear transmission, the transmission system of the rocker arm reduction box 4 is a five-stage cylindrical gear transmission, the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com