Method for steering a mining machine cutter

A mining machine, machine technology, applied in the field of manipulating mining machine cutters, can solve problems such as machine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

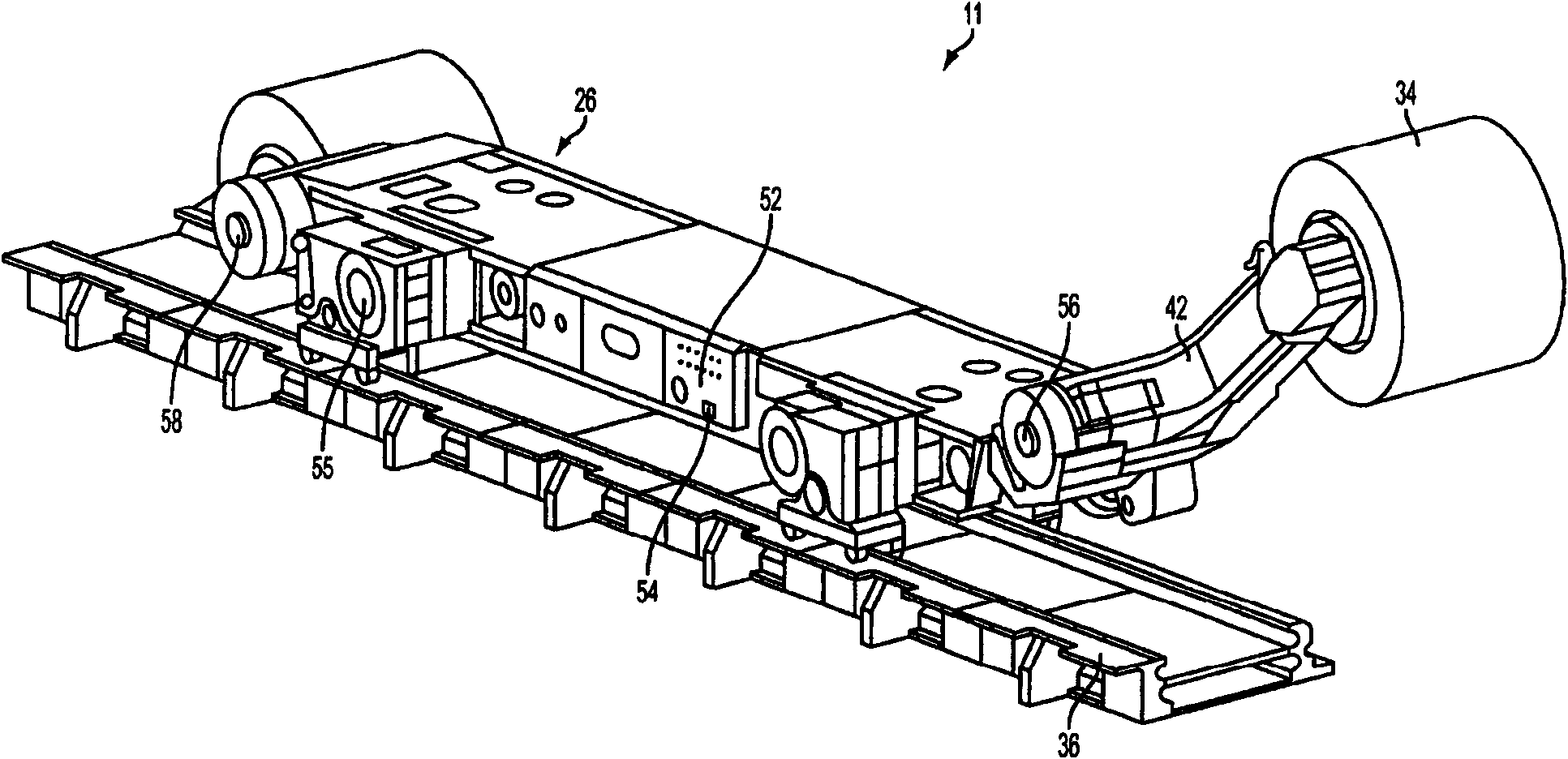

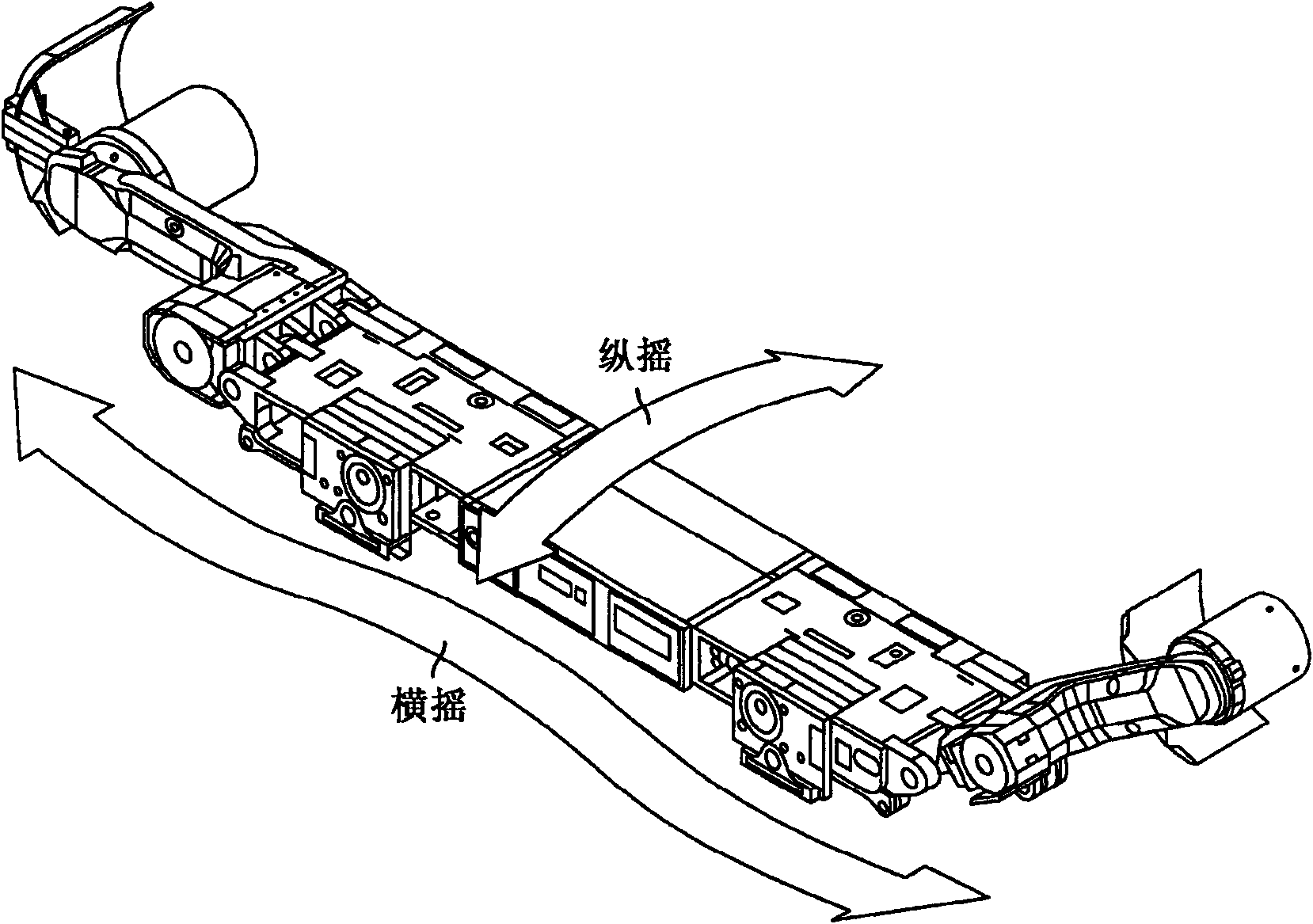

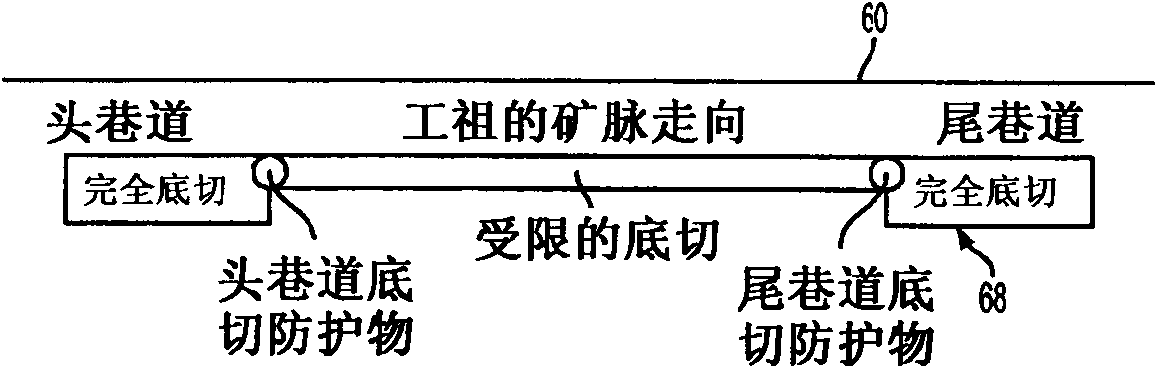

[0021] exist figure 1 One type of mining equipment 11 is illustrated in , which includes a mobile mining or cutting machine in the form of a cutter 26 having a rotatable cutting or mining head 34 which A plurality of cutting bits 38 are provided and are used to remove media from layers (not shown). The cutting head 34 is attached to a moving boom arrangement 42 which enables the position of the cutting head 34 to be adjusted relative to the mining floor. As cutting head 34 rotates and advances into the seam, coal is removed from the mining workers and received on collecting and conveying equipment 36 of coal mining equipment 11 . Conveyor 36 discharges mined material onto a separate stand-alone conveyor or mobile conveyor (not shown) for eventual conveyance out of the mine. The front cutting head 34 cuts the top part of the layer and the rear cutting head extracts the remaining part. The cutting machine is dragged along armored conveyors in the conventional manner as it cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com