Frequency division type rotary two-way material receiving device on production line and material receiving mode

A technology of receiving device and production line, applied in packaging and other directions, can solve the problems of inability to realize forward and reverse packing, limited work rhythm, and need to suspend incoming materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below through specific embodiments.

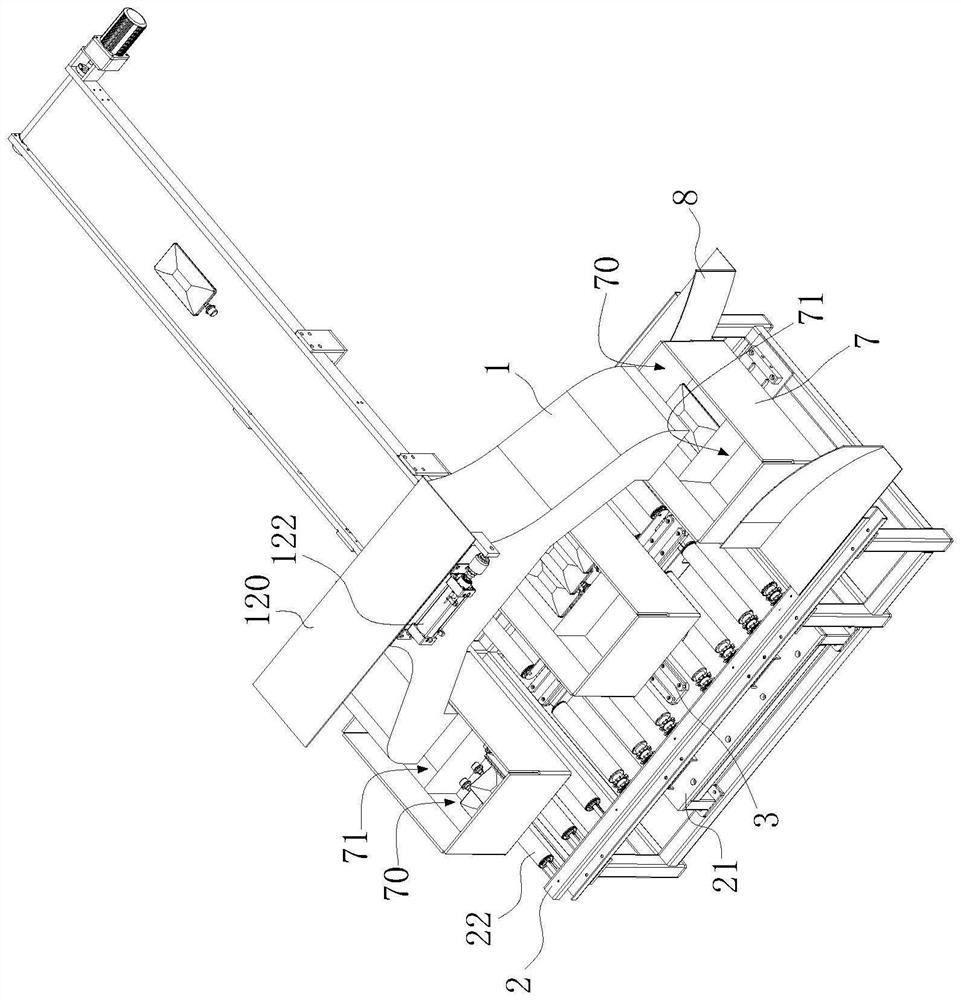

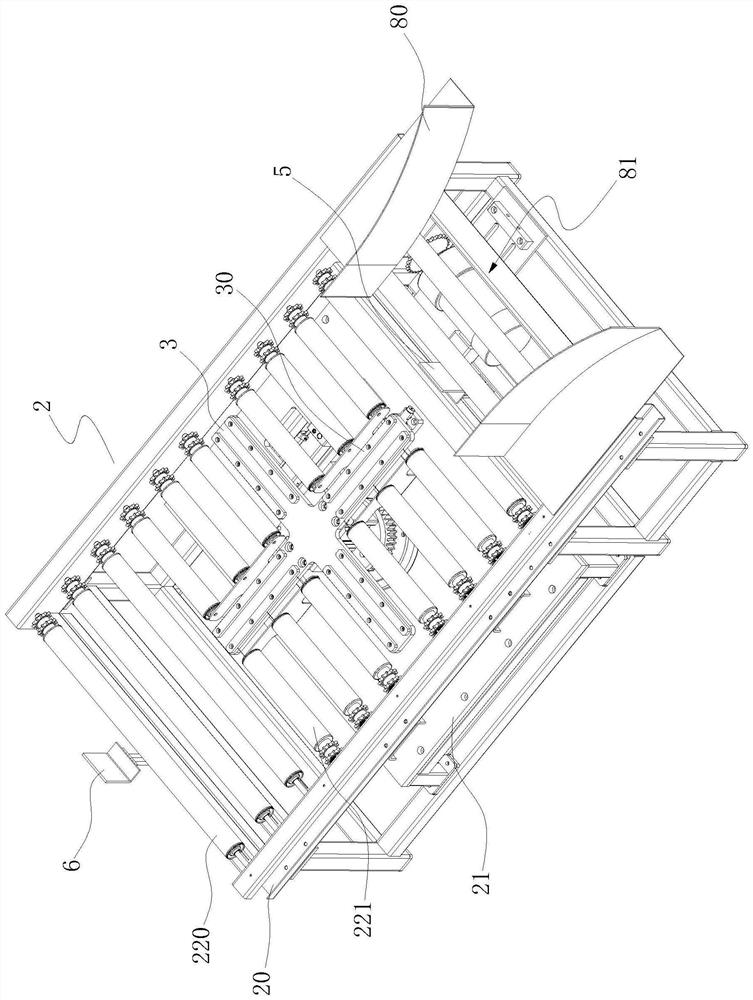

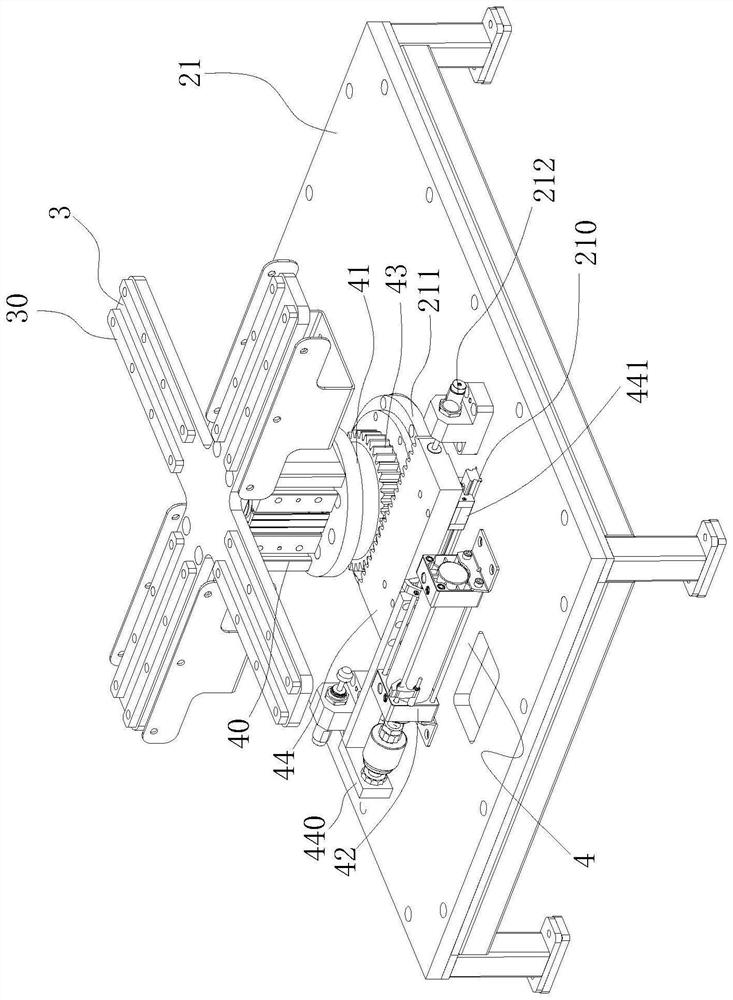

[0044] refer to Figure 1 to Figure 4, a frequency-division rotating two-way material receiving device and a material receiving method on a production line of the present invention include a two-way discharge hopper 1, a conveying platform 2, a lifting turntable 3, a driving device 4, a first limit mechanism 5 and a second limit mechanism Mechanism 6, the two-way discharge hopper 1 is arranged above the conveying platform 2, and the conveying platform 2 is used to convey the product box 7, and the conveying platform 2 is provided with a guiding mechanism 8, and the product box is guided by the guiding mechanism. Transported to the first packing point, the transfer point and the second packing point sequentially via the conveying platform, the product box 7 is divided into a first chamber 70 and a second chamber 71 of the same size, and the two-way output hopper 1 It has a first discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com