Powder conveyer device

一种粉末输送装置、粉末的技术,应用在输送散装物料、输送机、喷射装置等方向,能够解决难正常输送、粉末滞留、不利粉末等问题,达到解决粉末流动性较差、提高粉末流动性、提高输送能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

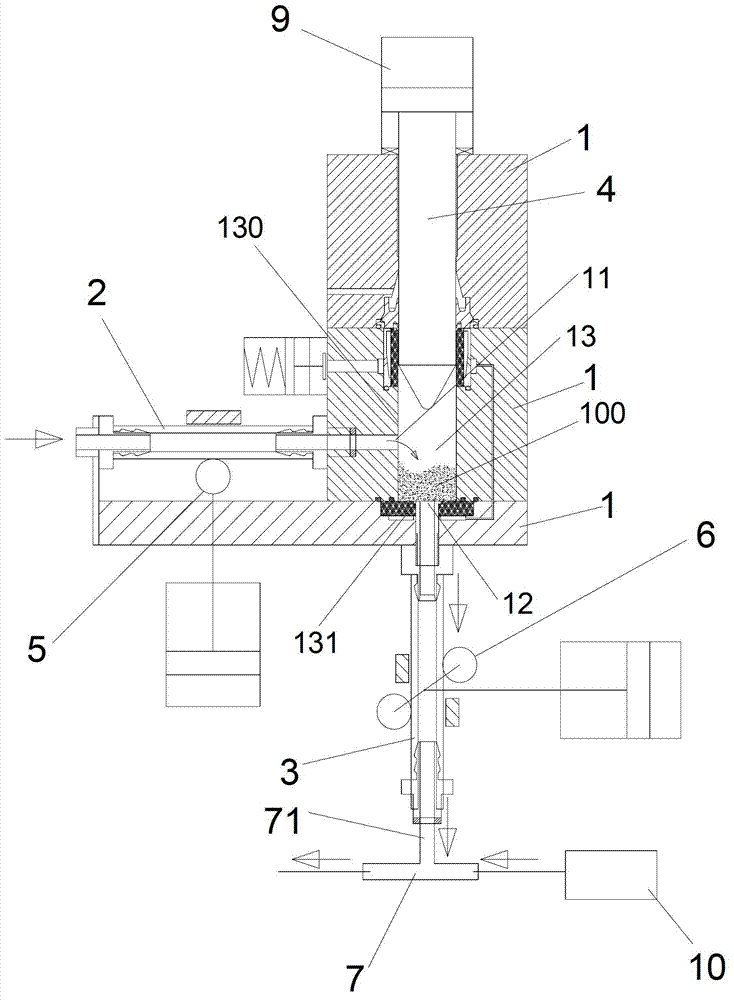

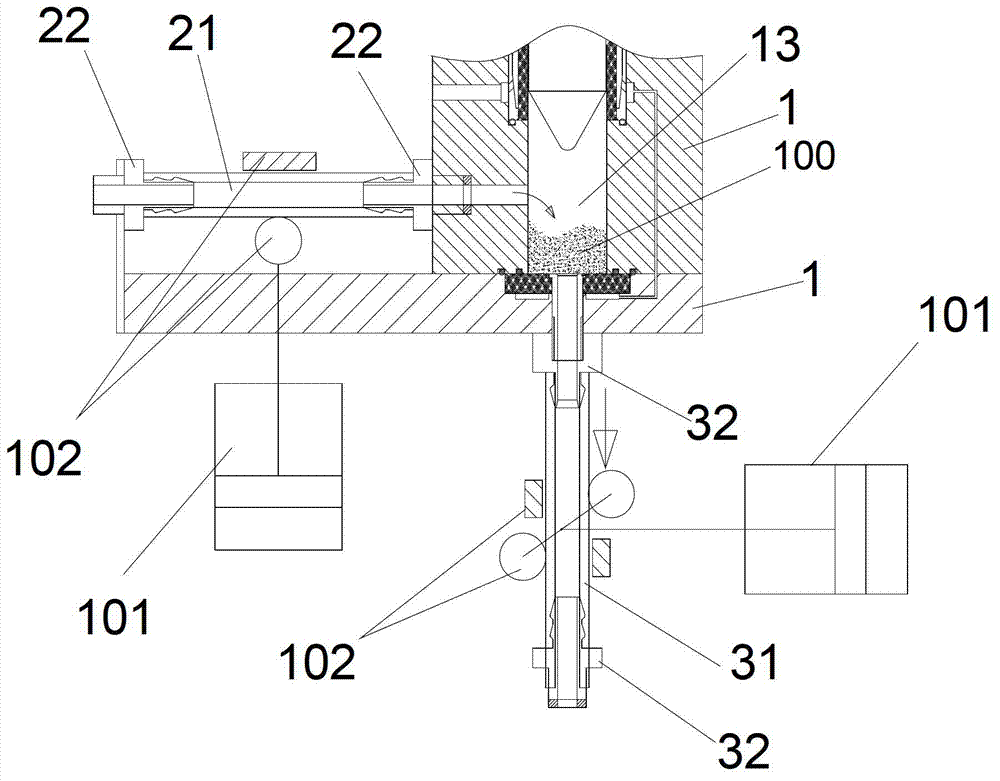

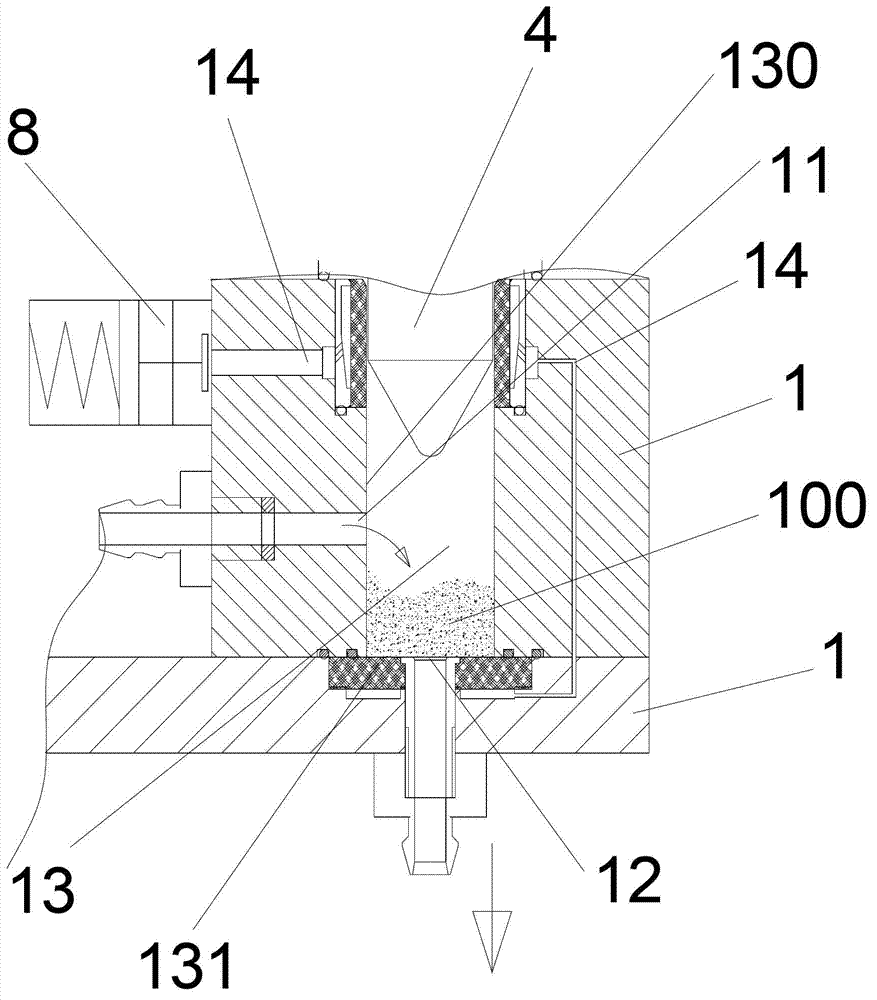

[0045]Embodiment one: if figure 1 , figure 2 , image 3 As shown, a powder conveying device includes a pump body 1, a powder suction plunger 4, a powder suction pipe 2, a powder discharge pipe 3, a powder suction pipe switch valve 5 and a powder discharge pipe switch valve 6, wherein the pump body 1 is provided with Transmission cavity 13, the powder inlet 11 is set on the transmission cavity 13 to connect with the powder suction pipe 2, the powder discharge port 12 is set on the transmission cavity 13 to connect with one end of the powder discharge tube 3; the powder suction plunger 4 is installed in the transmission cavity 13, It can move up and down along the conveying chamber 13. When the powder suction plunger 4 goes up, the powder suction pipe switch valve 5 opens the powder suction pipe 2, the powder discharge pipe switch valve 6 closes the powder discharge pipe 3, and the powder 100 is sucked and conveyed from the powder suction pipe 2 Cavity 13; when the powder suc...

Embodiment 2

[0048] Embodiment two: if Figure 4 As shown, a powder conveying device, the pump body 1 is provided with a left conveying chamber 13a and a right conveying chamber 13b, and the left powder suction plunger 4a and the right powder suction plunger 4b are respectively installed in the left conveying chamber 13a and the right conveying chamber 13b The left powder inlet 11a is connected to the left powder suction pipe (not shown in the figure) on the left transmission chamber 11a, and the left powder outlet 12a is connected to one end of the left powder outlet pipe 3a on the left transmission chamber 1a; The right powder inlet 11b is arranged on 11b to be connected with the right powder suction pipe (not shown in the figure), and the right powder outlet 12b is arranged on the right delivery chamber 1b to be connected with one end of the right powder outlet pipe 3b; The powder pipe switch valve is controlled, the right powder suction pipe is controlled by the right powder suction pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com