Cloth conveying device for textiles

A cloth conveying and chainring technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of worker safety risks, low work efficiency, long time consumption, and high labor intensity of workers, so as to increase efficiency and reduce Labor intensity, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

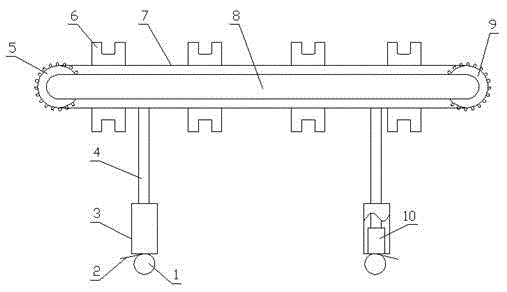

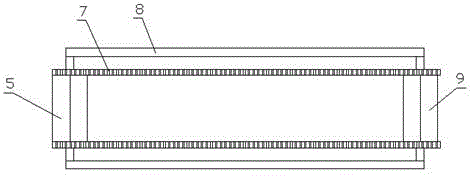

[0020] Such as figure 1 , figure 2 As shown, the cloth conveying device for weaving has a structure comprising a frame 8; the two ends of the frame 8 are respectively fixed with a driven tooth plate 5 and a driving tooth plate 9, and during use, the driven tooth plate 5 acts to The power chain 7 turns, and the driving chain 9 plays the role of providing power to the power chain 7. The driving chain 9 is driven by internal electric power; the outer surface of the driven chain 5 and the driving chain 9 are engaged with a ring Power chain 7, when in use, ring-shaped power chain 7 engages with the teeth of the tooth plate, drives power chain 7 to move by the rotation of active tooth plate 9.

[0021] In the above embodiment, specifically, the upper surface of the dynamic chain 7 is provided with a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com