Positive pressure pneumatic transmission system and method

A pneumatic conveying system and pneumatic conveying technology, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of increasing equipment costs, high valve costs, and difficulty in finding valves, so as to improve conveying efficiency and overcome valve costs Too high, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

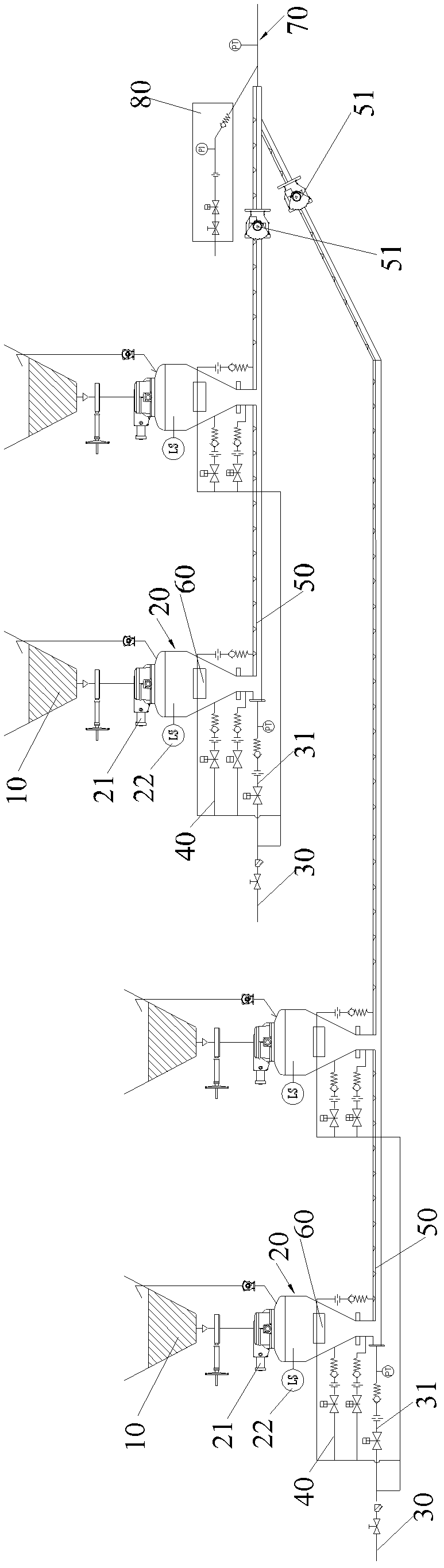

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0027] The pneumatic conveying system is very sensitive to the particle size and concentration of the conveyed material, especially for long-distance and coarse-grained materials, the stability of the conveying system is very high. For example, in thermal power plants, the quality of coal is getting worse day by day, and the particle size distribution of coal ash after combustion becomes coarser and unstable, which makes the conveying system prone to clogging accidents, resulting in severe accidents of production and shutdown. Therefore, the conveying system The stability requirements are higher.

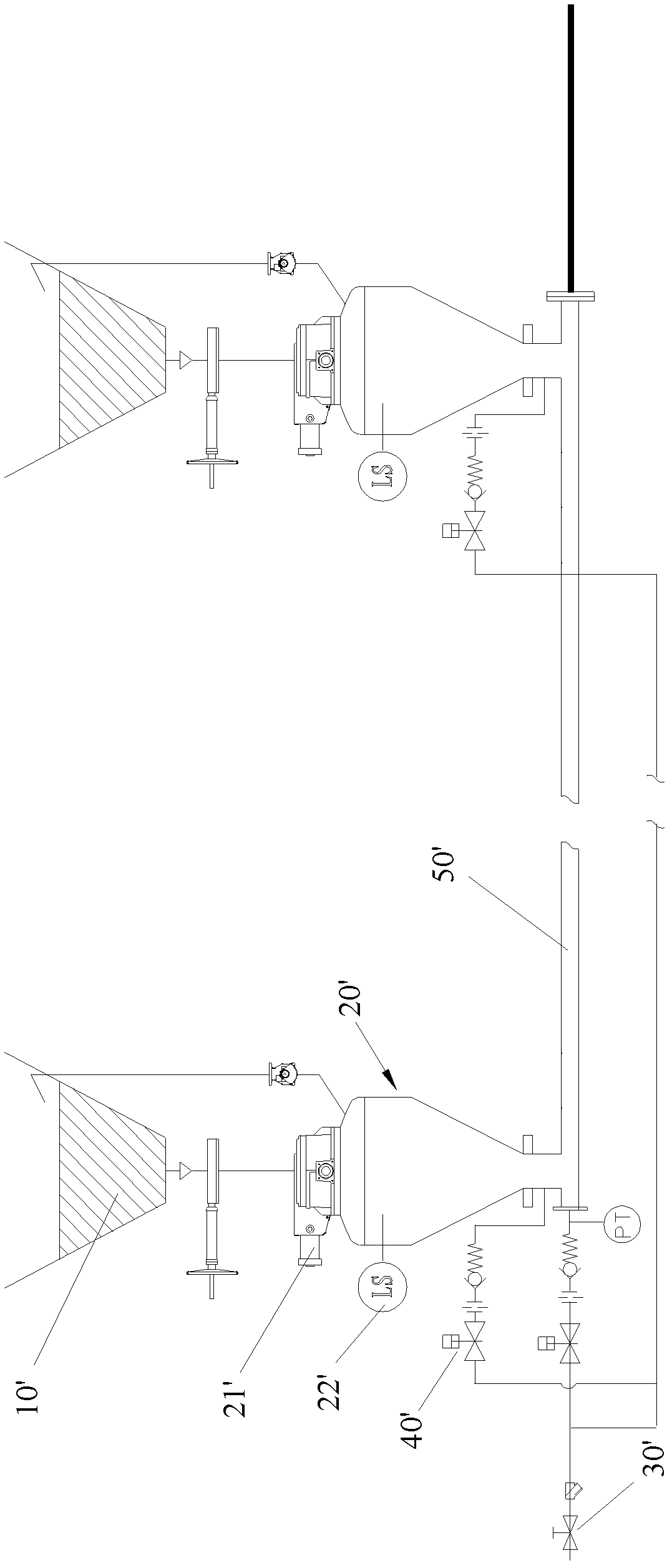

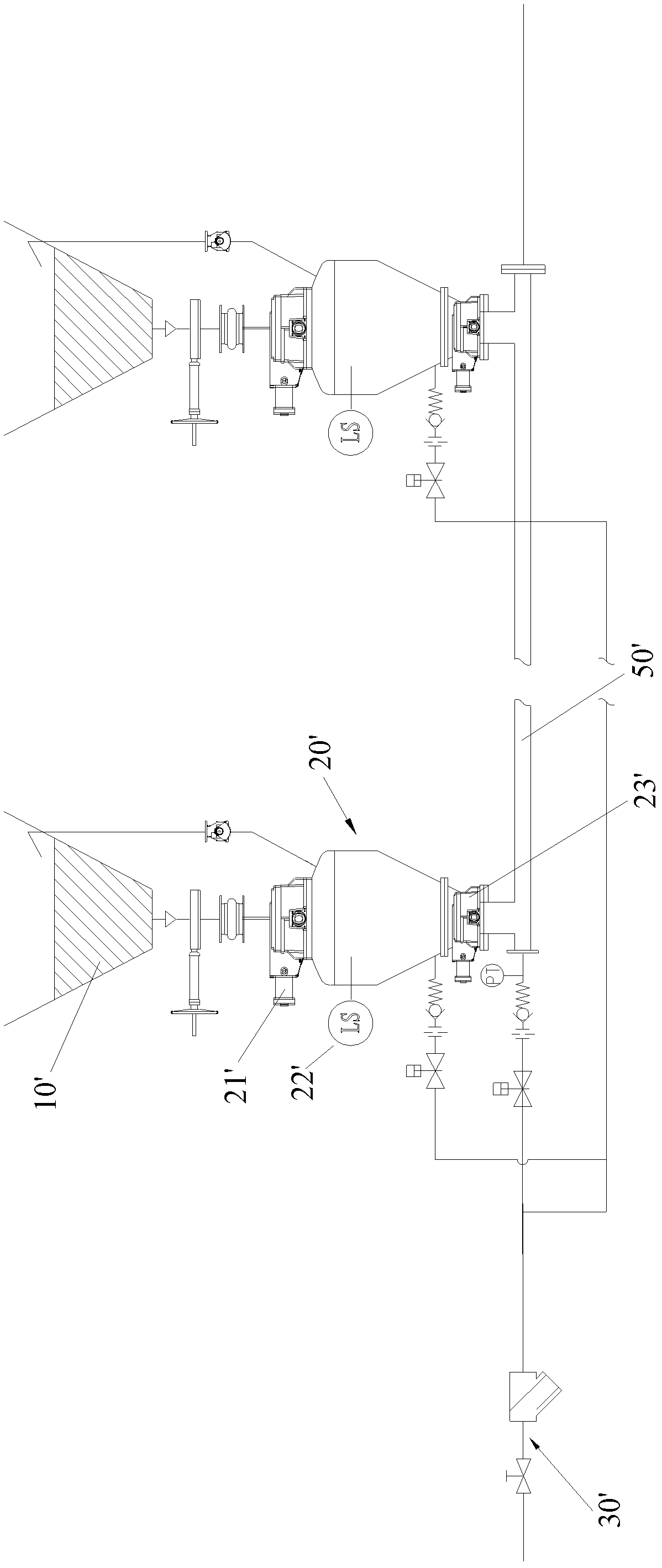

[0028] Such as image 3 As shown, the present invention provides a kind of positive pressure pneumatic conveying system, comprises air inlet pipe 30, and its first end communicates with the first compressed air source; end; a plurality of warehouse pumps 20, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com