Battery piece conveying mechanism for automatic series welding machine

A conveying mechanism and cell technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of long conveying time, slow conveying efficiency, and falling cells, and achieve improved conveying efficiency and continuous The effect of conveying and preventing film drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below according to the drawings and embodiments.

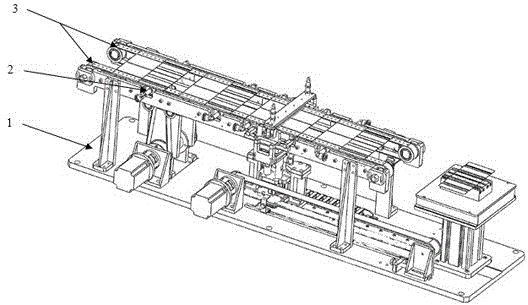

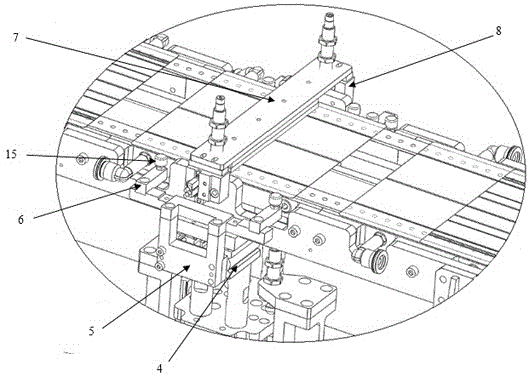

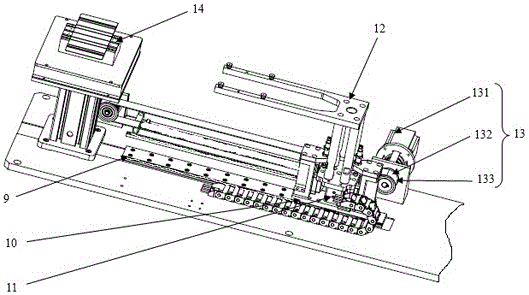

[0020] Such as figure 1 As shown, a cell conveying mechanism for an automatic stringer according to an embodiment of the present invention includes:

[0021] The conveying device, the conveying device includes a bottom plate 1, two conveyor belt brackets symmetrically distributed are installed on the bottom plate 1, an adsorption block 2 is installed on the conveyor belt bracket, the adsorption block 2 is covered with a conveyor belt 3, and the adsorption block 2 and the conveyor belt 3 Adsorption holes are respectively opened on the contact surface, and the adsorption block 2 is provided with a trachea hole, and the trachea is vacuumed, so that the adsorption block 2 can absorb the cells through the adsorption holes opened on the adsorption block 2 and the conveyor belt 3, so that the cells are closely attached to each other. on conveyor belt 3.

[0022] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com