Vertical material collecting device

A technology for retrieving devices and parts, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as insufficient suction, slow suction speed, plate drop, etc., and achieve the effect of sufficient contact and stable suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

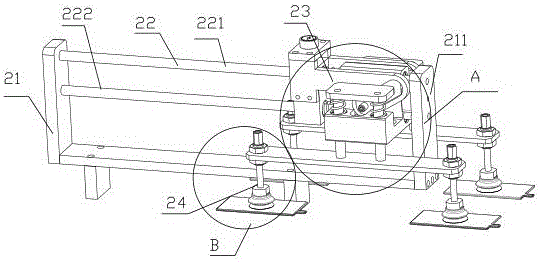

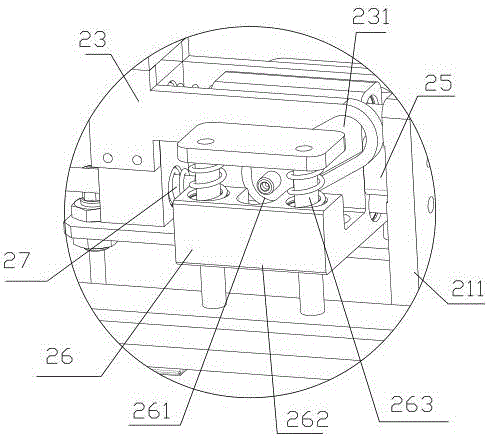

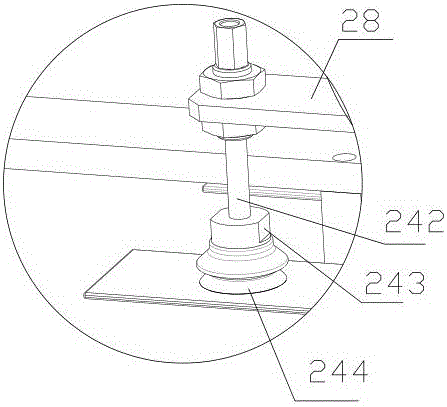

[0035] Example 1, such as figure 1 , figure 2 and image 3 Shown, a kind of vertical pick-up device, comprises suction member 24, also comprises pick-up rack 21, and one side of pick-up rack 21 is provided with baffle plate 211, and pick-up rack 21 is provided with guide rail 22; Also included in The slide base 23 that slides on the guide rail 22 is provided with an inclined rail 231 that is inclined. The inclined rail 231 includes a high end and a low end, and the lower end of the high end is closer to the baffle plate 211; The moving block 26 connected to the suction member 24 is connected with a cam 261 , and the cam 261 slides in the ramp 231 .

[0036] A baffle 211 is provided on one side of the retrieving rack 21 , and the user drives the sliding base 23 to slide on the guide rail 22 through a driving device, such as a motor or an air cylinder, and approaches the baffle 211 . In the process of approaching, the cam 261 has been kept at the high position end, so the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com