Glass sucking device

A suction device, glass technology, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of glass damage placement, inconvenient detection process, affecting detection efficiency, etc., to achieve accurate dripping operation and dripping action. And the effect of placing the action is coherent and smooth, and the operation is simple and efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

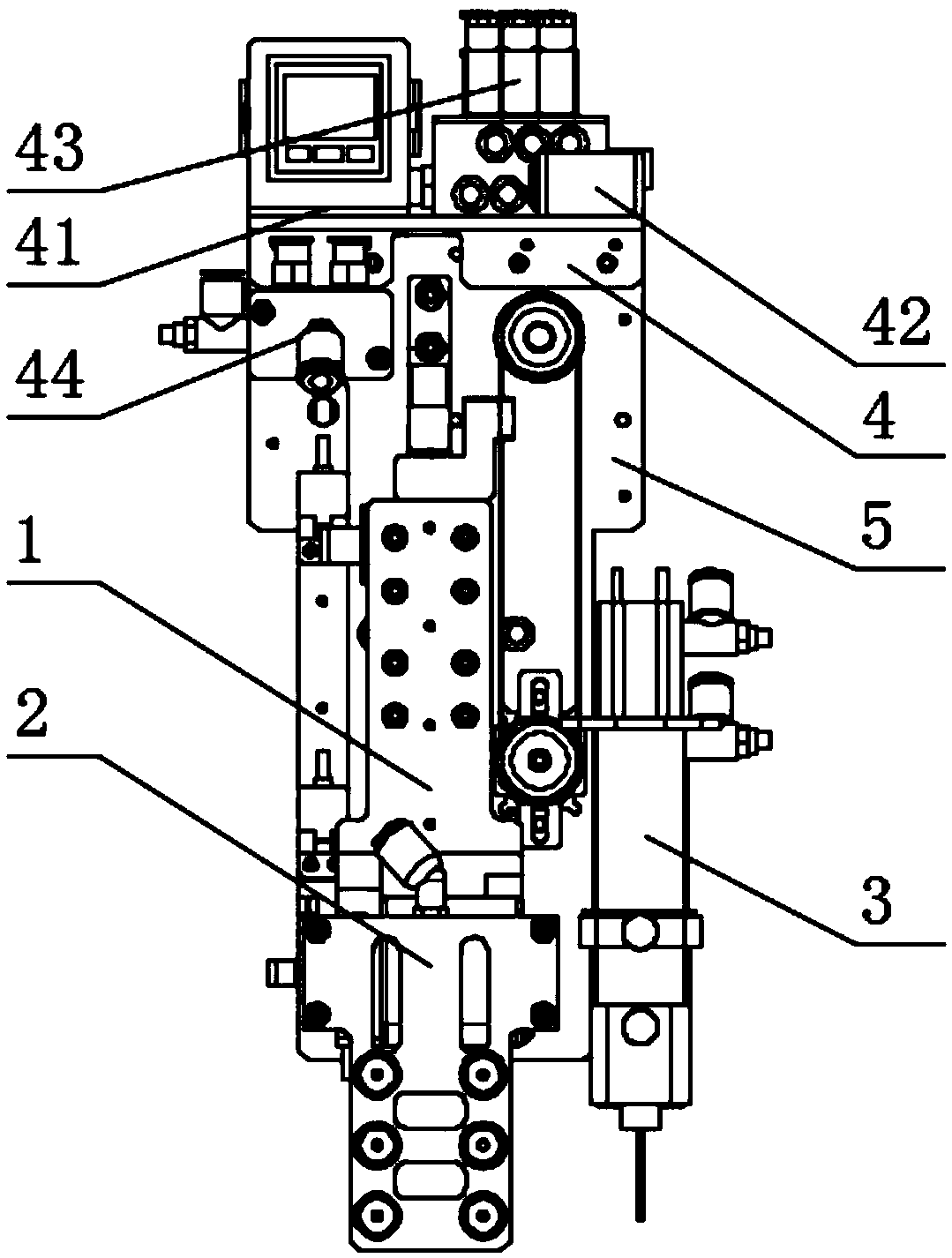

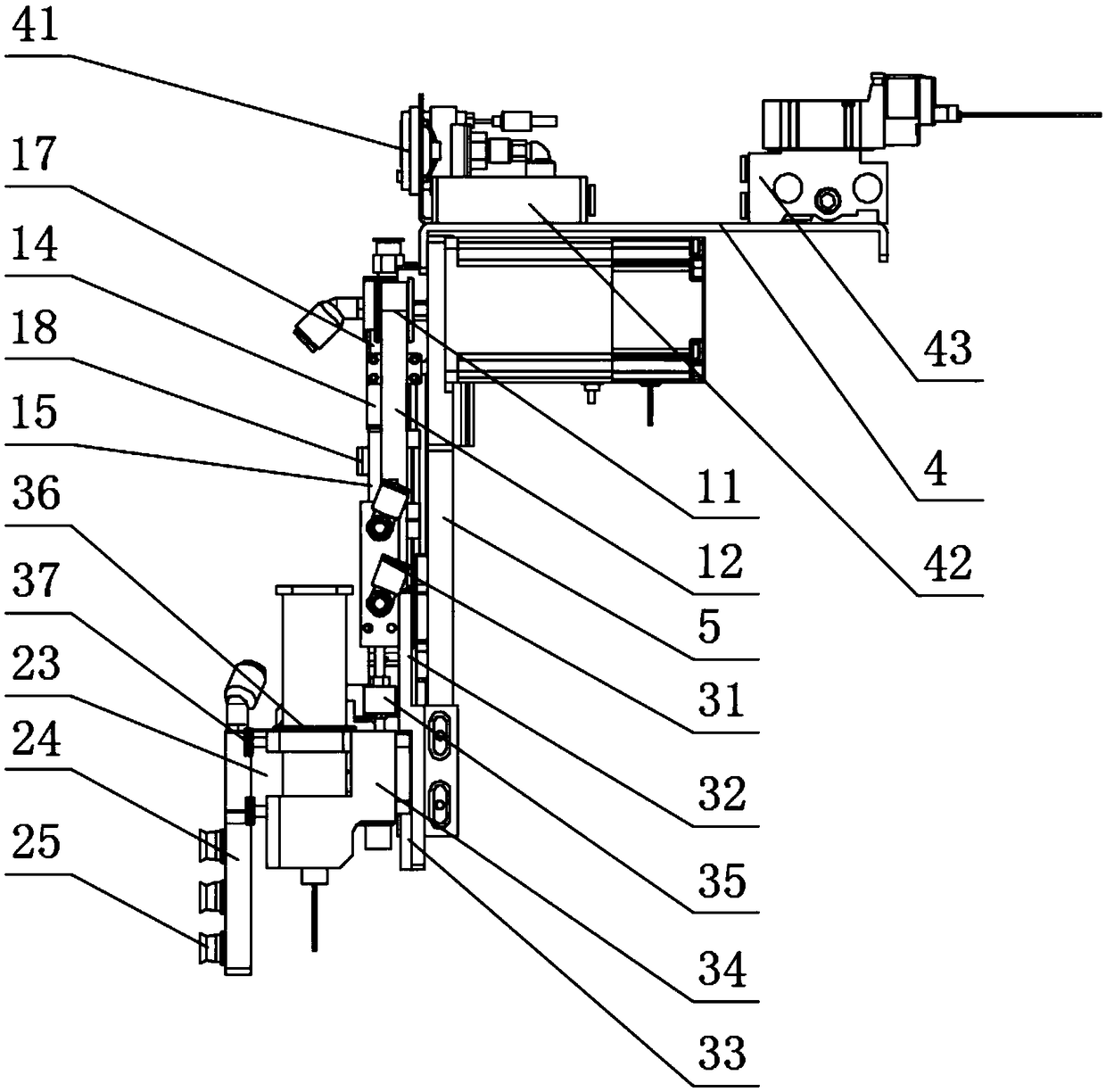

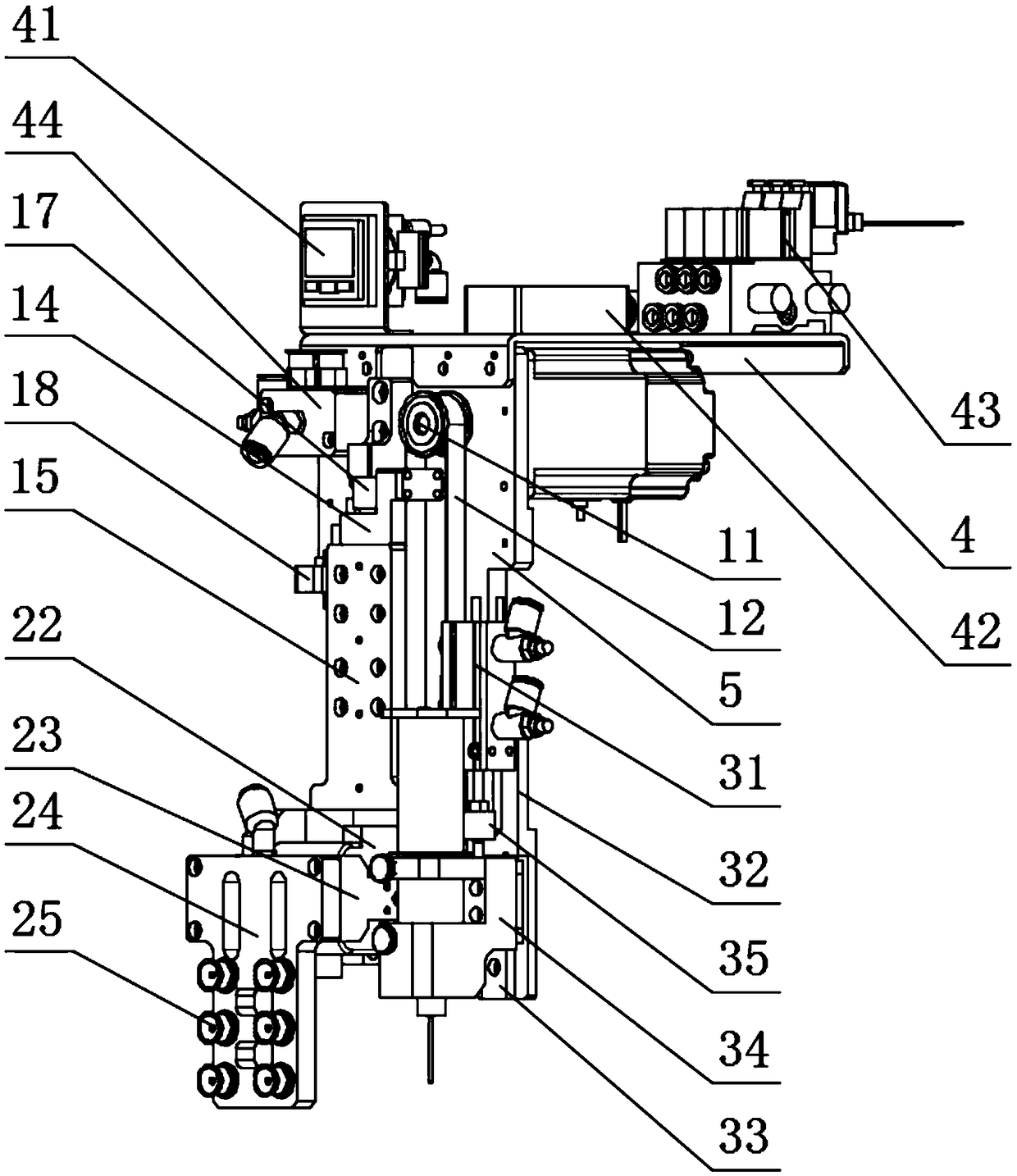

[0030] In order to further illustrate the above-mentioned purpose, technical scheme and effect of the present invention, the present invention will be described below in conjunction with the accompanying drawings and relevant known technical knowledge through the embodiments:

[0031] like figure 1 As shown, a glass suction device in this embodiment includes a fixed base plate 5, a transmission assembly 1, a rotating assembly 2 and a dispensing assembly 3; the transmission assembly 1 is arranged on the fixed base plate 5, and the fixed base plate 5 is fixed to an X-axis moving assembly , can be driven by the X-axis moving assembly to move horizontally; the rotating assembly 2 is fixedly connected to the transmission assembly 1, and the transmission assembly 1 moves the rotating assembly 2 up and down; the rotating assembly 2 is provided with a suction cup 25 to absorb glass, and the rotating assembly 2 can drive The sucked glass is rotated at a certain angle to complete the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com