Continuous unshipping machine capable of realizing unshipping from two sides and unshipping method

A ship unloader and cabin technology, applied in the field of ship unloading equipment, can solve the problems of inability to realize double-sided unloading in sea surveys, inability to fully exert high-efficiency effects, and strict requirements for loading ship types, etc., to achieve convenient processing and assembly, compact structure, The effect of good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

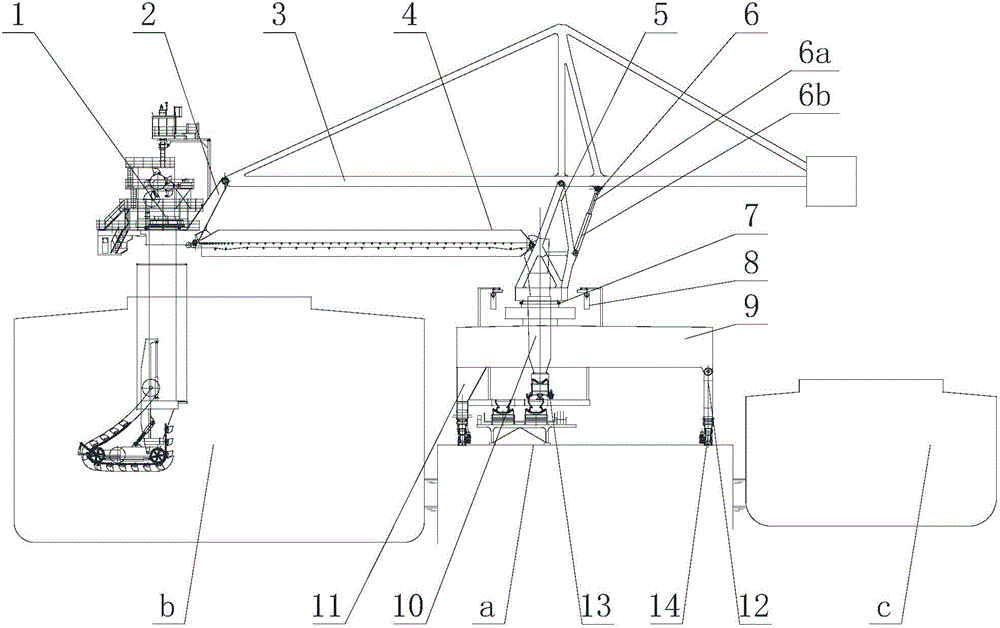

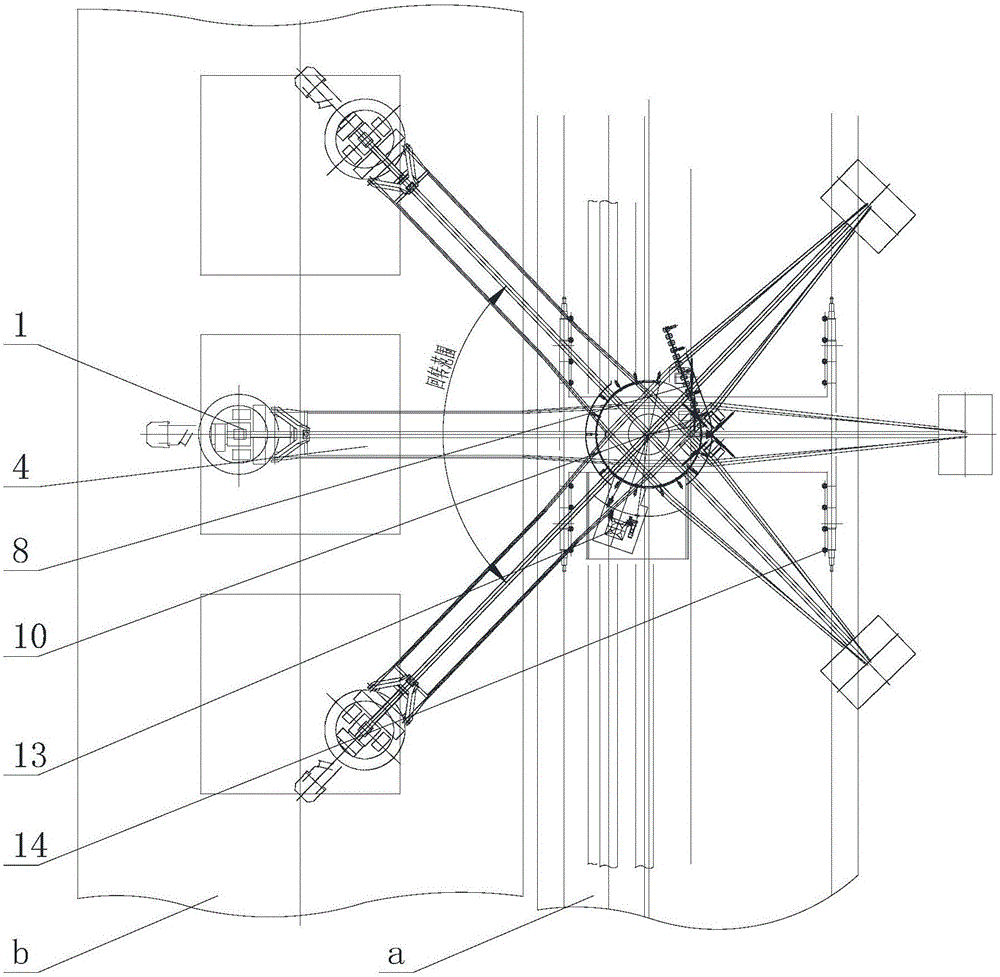

[0045] As shown in the figure, a continuous ship unloader for double-sided unloading includes a mast 9, and the two sides of the bottom of the mast 9 are respectively equipped with a sea-side door leg 11 and a land-side door leg 12, and the upper part is passed through a slewing bearing 7 A swivel frame 5 is installed to support the weight of the upper structure of the complete machine.

[0046] The bottoms of the sea-test gate leg 11 and the land-side gate leg 12 are respectively provided with cart running mechanisms, which carry the weight of the whole machine and can drive the whole machine to run along the wharf track.

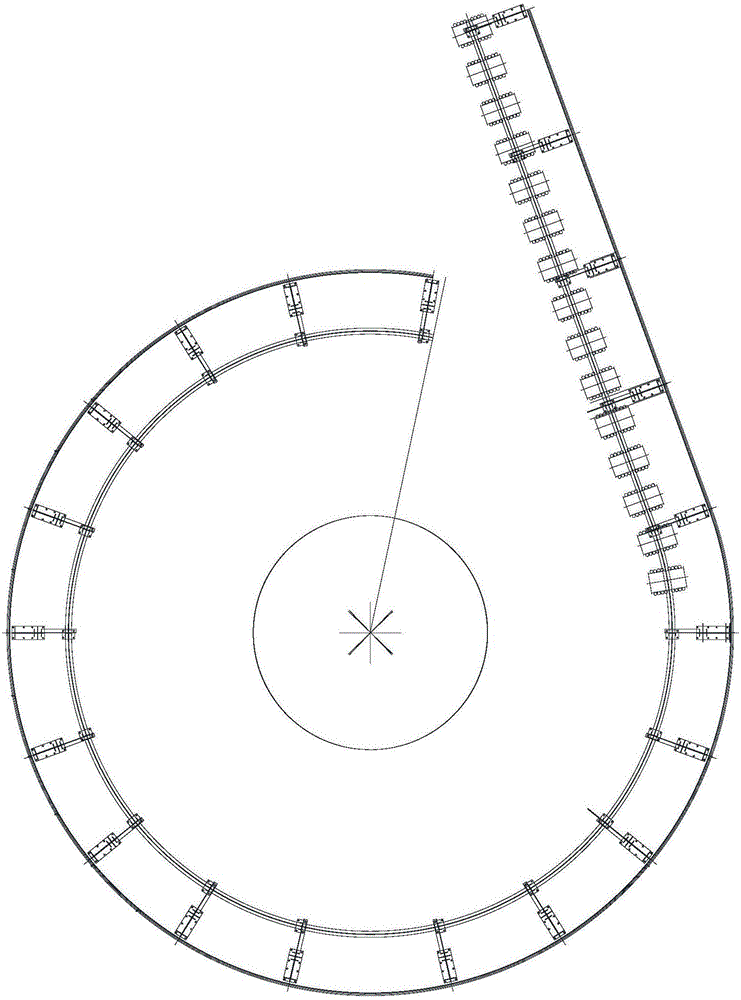

[0047] The slewing frame 5 is a truss structure, and the center is provided with a central chute 10 for receiving materials. The central chute 10 is used for receiving materials thrown from the boom belt conveyor. Feeding belt conveyor 13, the bottom of the feeding belt conveyor 13 is provided with a pier belt conveyor.

[0048] The upper part of the slew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com