C type continuous elevator

A lifter, a continuous type of technology, applied in the field of machinery, can solve the problems of low equipment space utilization and large material displacement, and achieve the effect of high space utilization, continuous transportation, and easy up and down lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

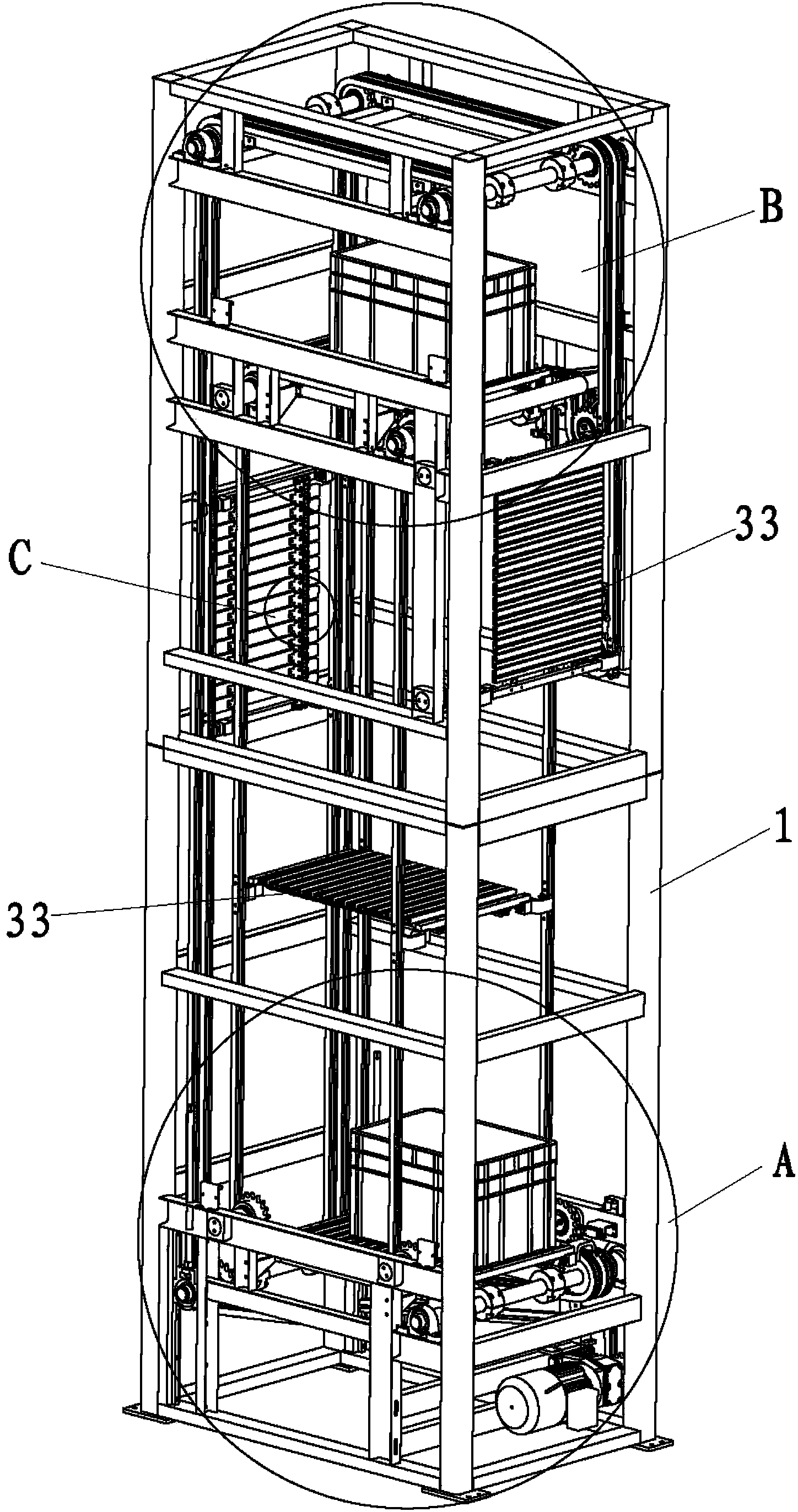

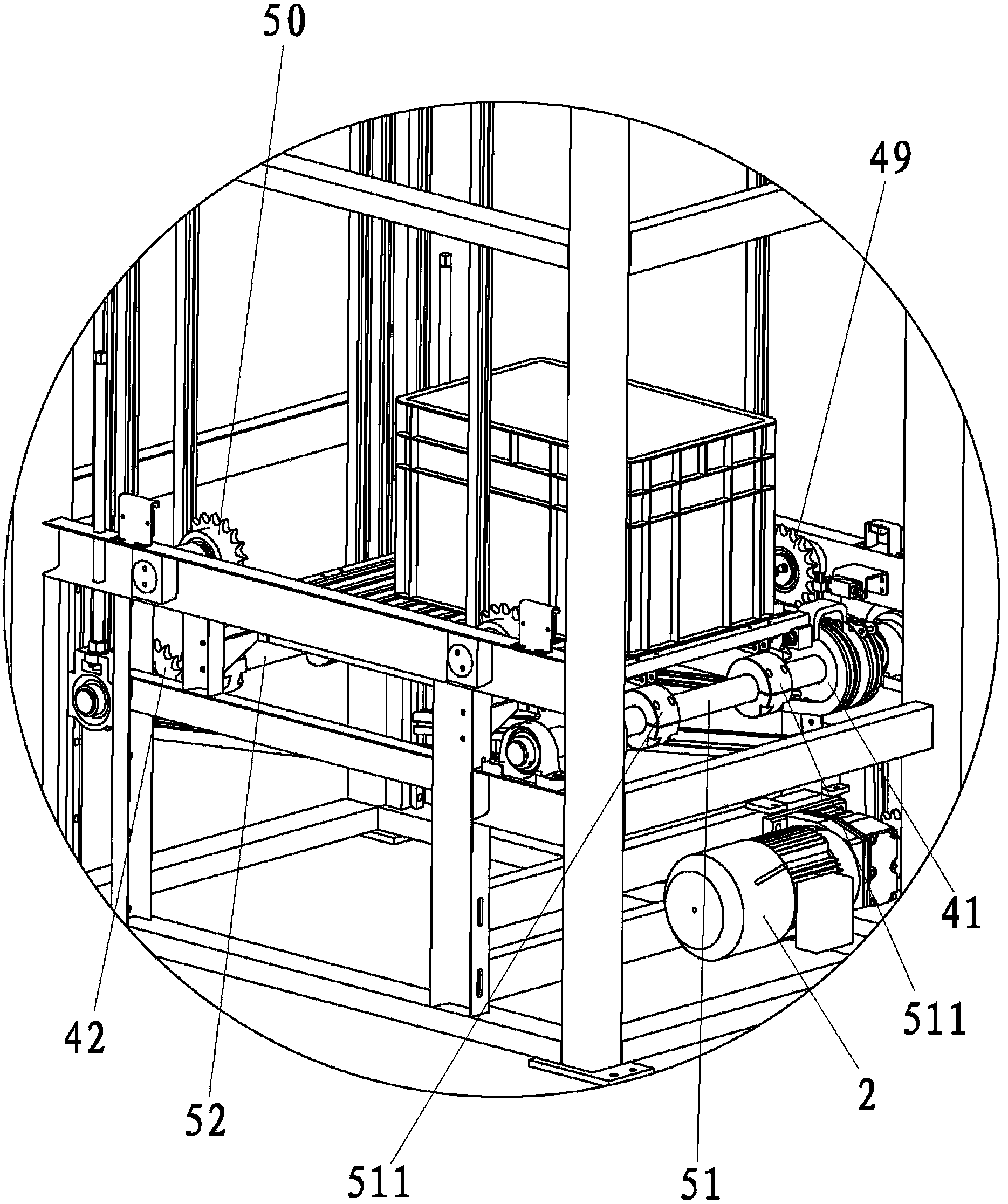

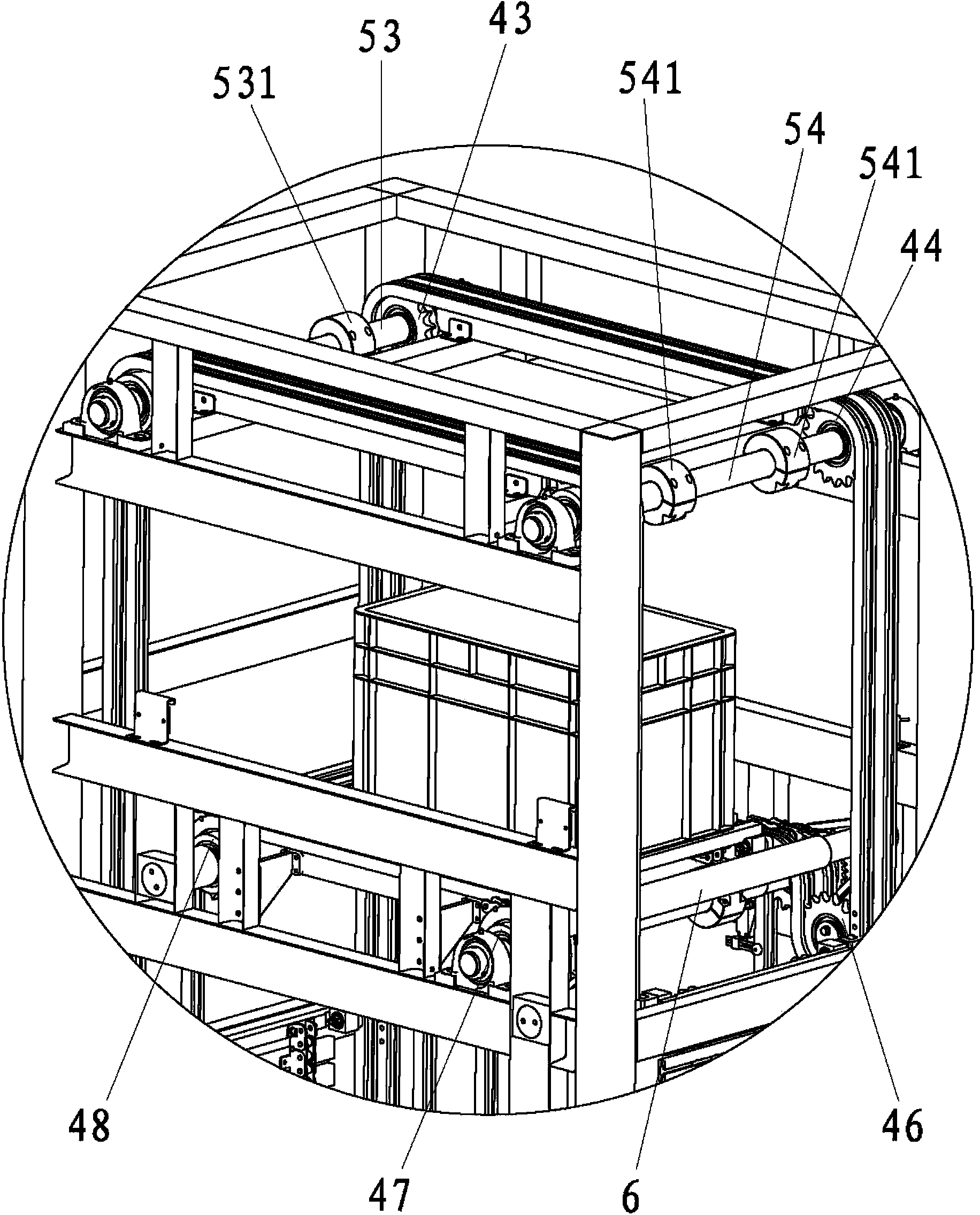

[0037] Example: such as Figure 1-8 As shown, a C-type continuous elevator includes a frame 1 with an upper entrance 11 and a lower entrance 12. The bottom of the frame 1 is provided with a driving device 2, which is generally a motor.

[0038] The frame 1 is also provided with a chain assembly connected to the driving device 2. The chain assembly includes two first chains 31 and two second chains 32. The two sides are respectively rotatably connected to the conveyor belt 33 corresponding to the side wall of the second chain 32, four first transmission sprockets 41, four second transmission sprockets 42, four third transmission sprockets 43, and four fourth transmission sprockets. Sprocket 44, two fifth transmission sprockets 45, two sixth transmission sprockets 46, four seventh transmission sprockets 47, two eighth transmission sprockets 48, two ninth transmission sprockets 49, two A tenth drive sprocket 50.

[0039] The upper entrance and exit 11 and the lower entrance and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com