Automobile door plate stamping die

A technology for stamping dies and door panels, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the speed of automobile manufacturing and the inability to replace punches, reducing the time for replacing dies, reducing weight, and improving The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

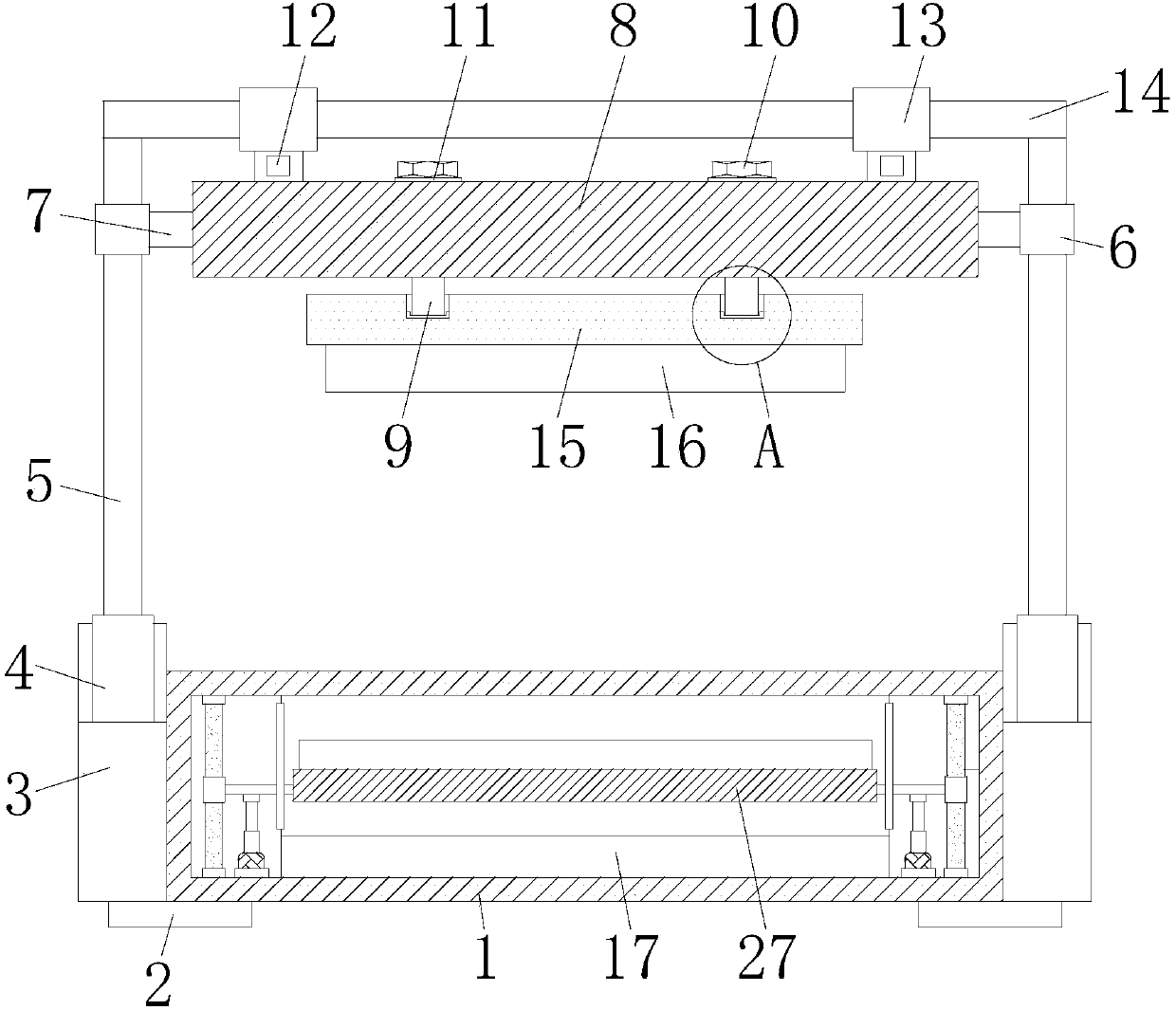

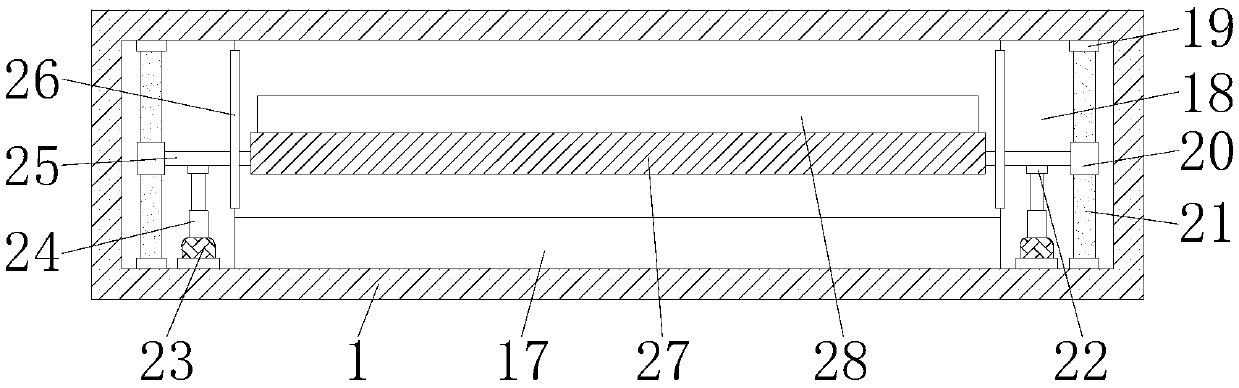

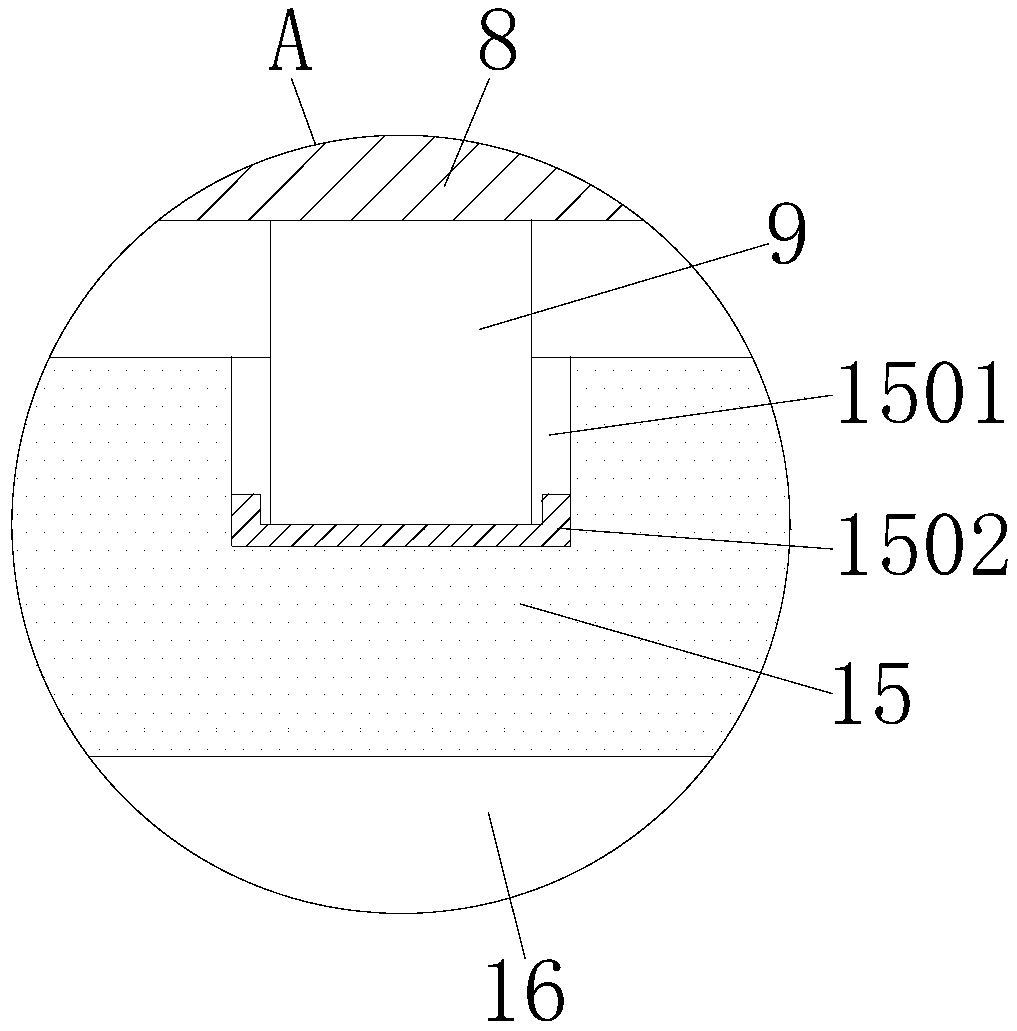

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] Please refer to Figure 1-Figure 3 As shown, the present invention provides a technical solution: a stamping die for an automobile door panel, including a base platform 1, and both sides of the base platform 1 are fixedly connected with connecting seats 3, the number of connecting seats 3 is two, and two The top of the connecting seat 3 is fixedly connected with the fixed seat 4, the number of the fixed seat 4 is four, and the tops of the four fixed seats 4 are all fixedly connected with the installation slide bar 5, and the end of the installation slide bar 5 is far away from the fixed seat 4. It is fixedly connected with the lower surface wall of the mounting plate 14, and the surface of the mounting plate 14 is fixedly connected with a gravity pressure cylinder 13. The model of the gravity pressure cylinder 13 is 100T-3000T. Cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com