Cloth cutting and conveying device and multi-type packaging integrated machine

A conveying device and cutting technology, which is applied in the field of fabric processing, can solve problems such as low efficiency, easy generation of static electricity, and inaccurate position, so as to save costs, improve applicability, and avoid unreasonable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

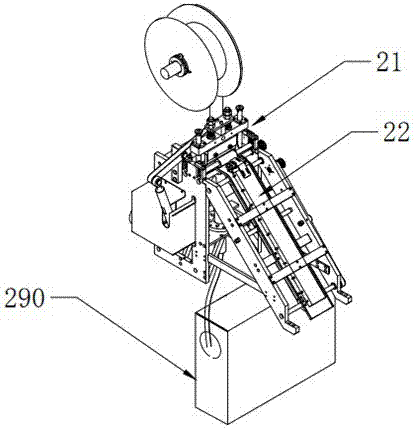

[0086] In this embodiment, a cloth cutting and conveying device for a packaging machine, such as figure 1 As shown, it includes a cutting part 21 and a conveying part 22;

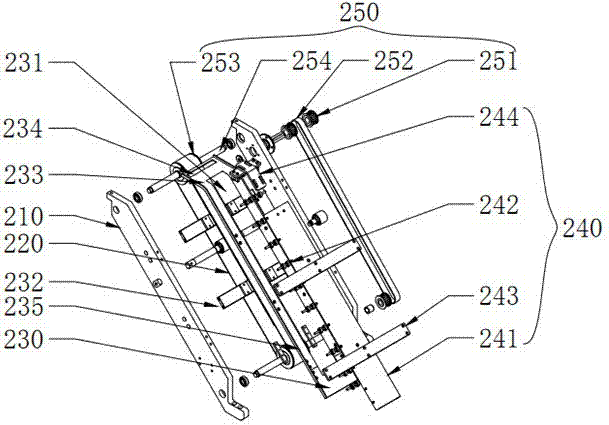

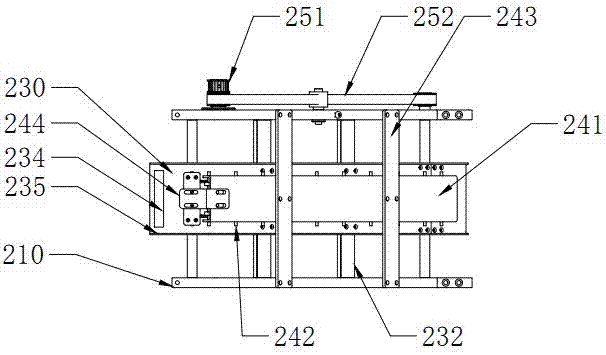

[0087] The structural decomposition diagram of the transmission part is as follows: figure 2 , including support frames 210 on both sides, a conveyor belt 220 with a width smaller than the width of the cloth, a sheet metal conveying plate 230, and a pressing part 240 arranged above the conveyor belt 220; There is a notch 231 matching the conveyor belt 220 in the middle; the conveyor belt 220 is installed at the notch 231 and the surface is flush with the surface of the conveyor plate 230, and the conveyor belt is connected to the driving part 250; the support frame 210 is connected to The cutting part 21, the cutting part 21 sends the cloth after cutting to the conveying plate 230 by the traction roller 272; The driving pulley 251, the transmission belt 252, and the synchronous pulley 253 are installed a...

Embodiment 2

[0093] Such as Figure 5 and Figure 8 As shown, a multi-type packaging all-in-one machine includes a frame 100 and a conveyor belt 110 for conveying materials. The conveyor belt 110 is installed on the frame 100, and several sequentially connected Limiting pieces 111, a limiting groove for placing materials is formed between every two limiting pieces 111.

[0094] The frame 100 is spliced into three layers from bottom to top through the detachable connecting plate 101 and the square tube 102, which are respectively the lower layer, the middle layer and the upper layer. device, a material pushing device for pushing materials into the packaging film, and a packaging device for sealing the packaging film; the frame in this patent embodiment adopts an upper, middle and lower three-layer structure, and is welded by square tubes 102 Each layer is laid with steel plates of corresponding thickness for placing different parts. At the same time, the whole frame is composed of front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com