Patents

Literature

42results about How to "Reasonable division of labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

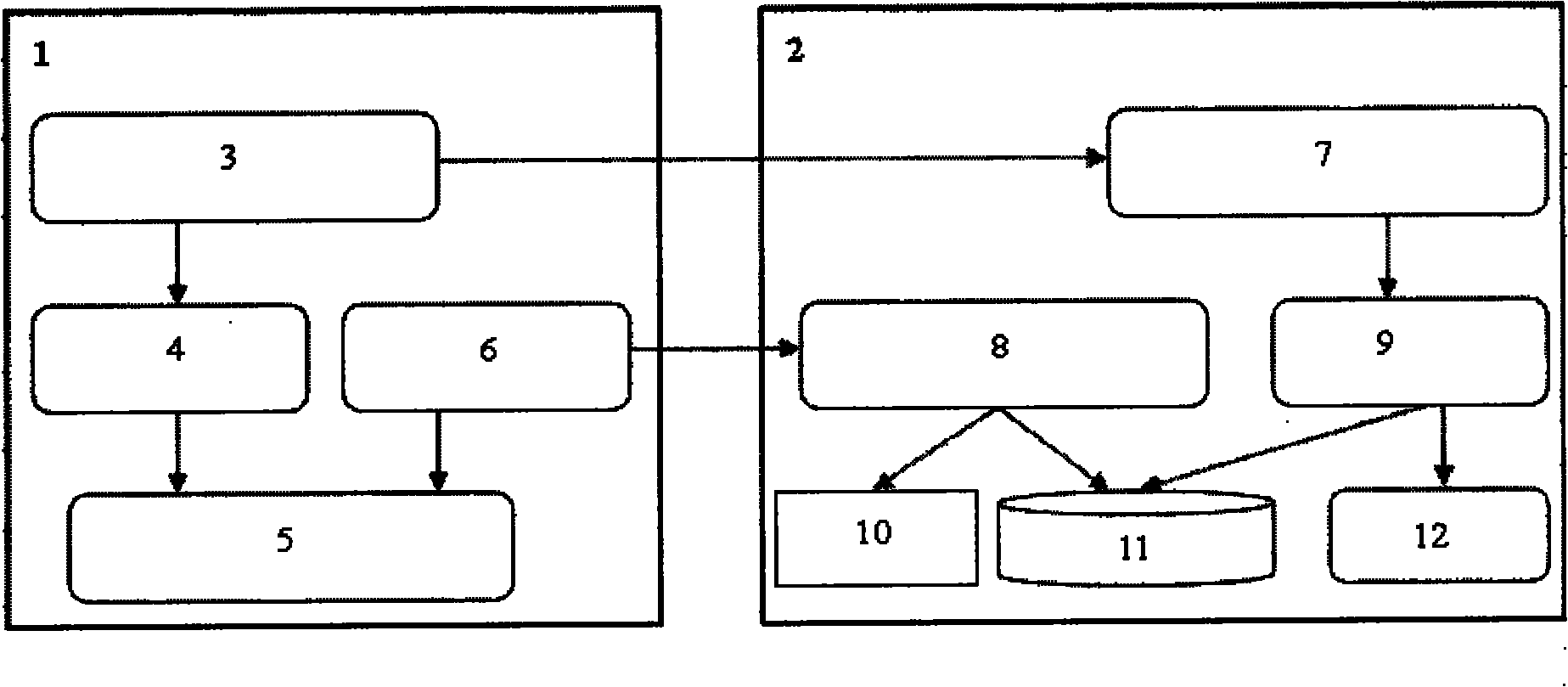

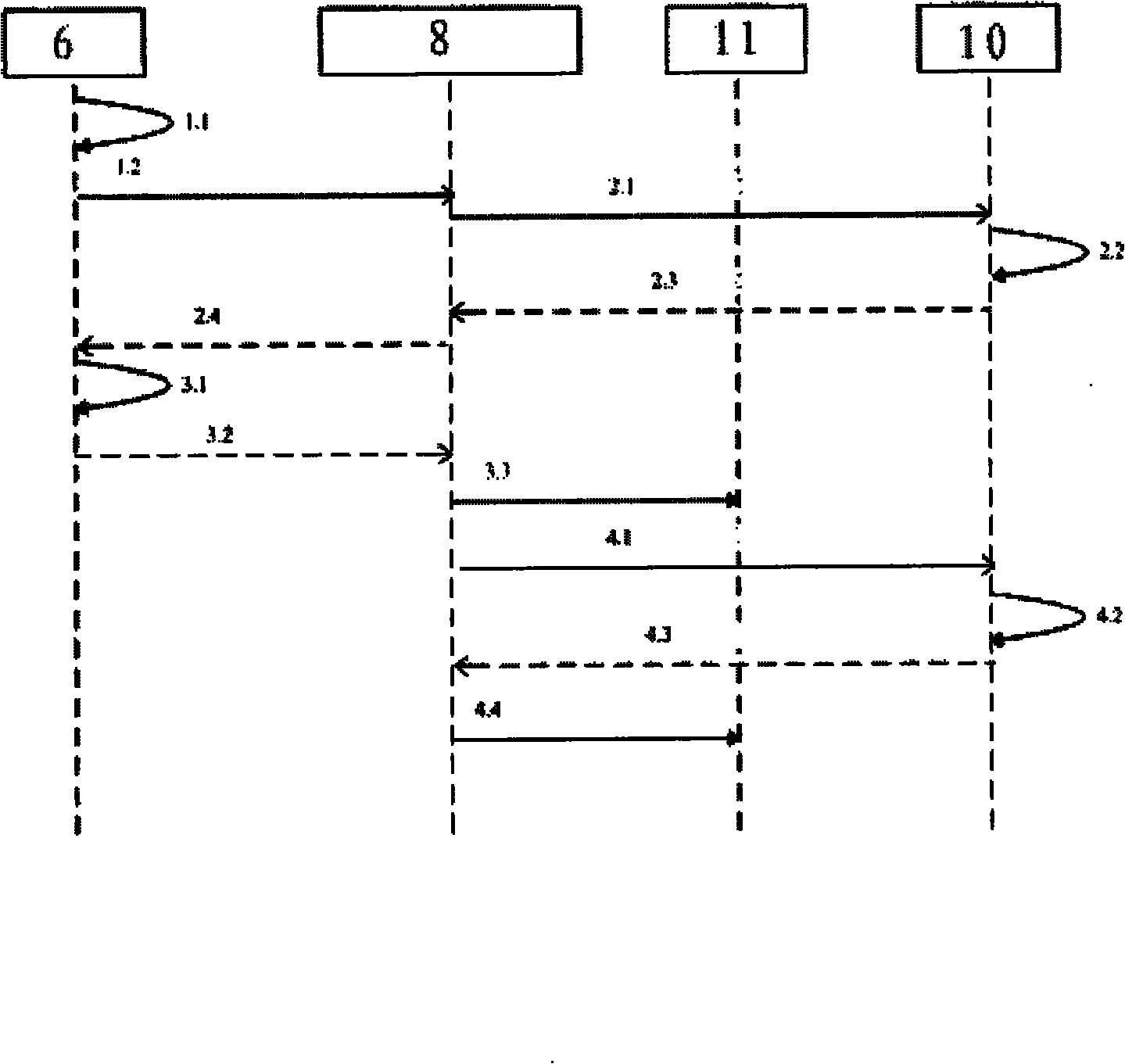

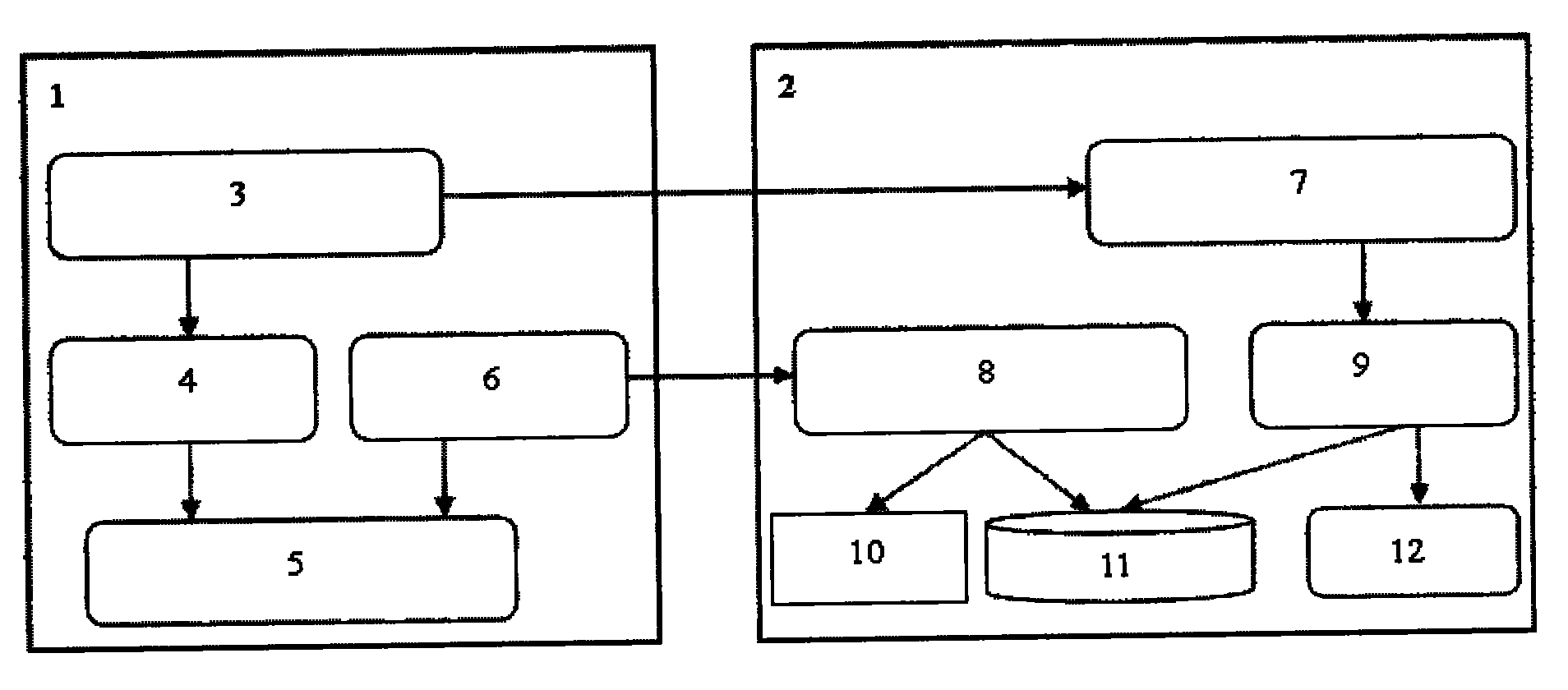

Key management system and method for bank terminal security equipment

InactiveCN101877157AImprove development efficiencySave human resourcesComplete banking machinesMultiple keys/algorithms usageComputer terminalManagement system

The invention relates to a key management system and a key management method for bank terminal security equipment. The system comprises a bank service terminal and a bank service background; the bank service terminal comprises the bank terminal security equipment and a key management agent component; and the bank service background comprises a KMC, a key database, an encoder and a service application system server, wherein the key management agent component is used for acquiring a working key from the KMC and writing the working key into the bank terminal security equipment; and the KMC provides registration service, key transmitting service and automatic key update service for the bank terminal security equipment. The key management system and the key management method for the bank terminal security equipment can effectively realize key management of the bank terminal security equipment, and separate the key management from a bank service application system at the same time so that each service application system does not need to implement complex key management logics any more and the implementing complexity of the service application system is reduced.

Owner:戴宇星

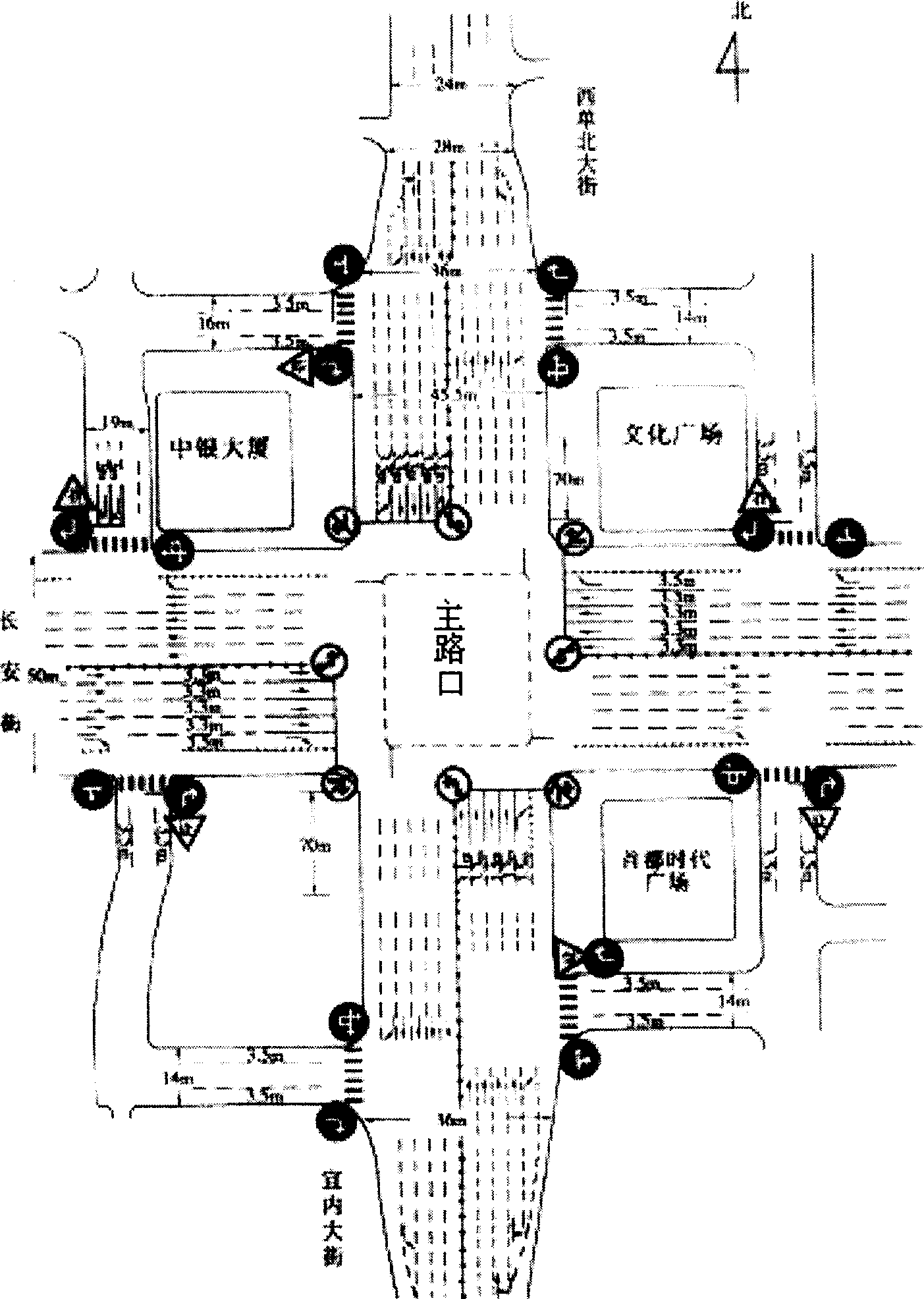

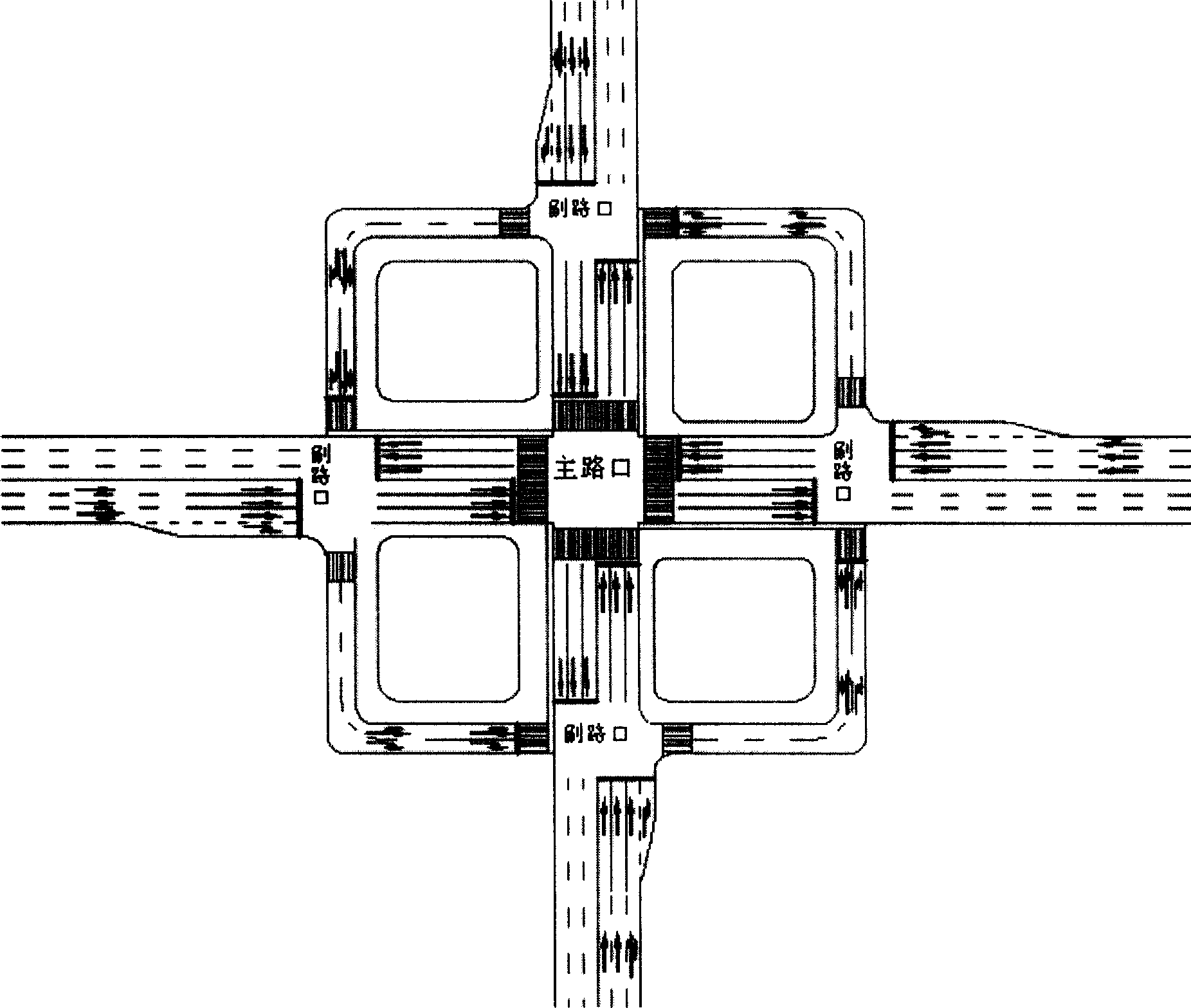

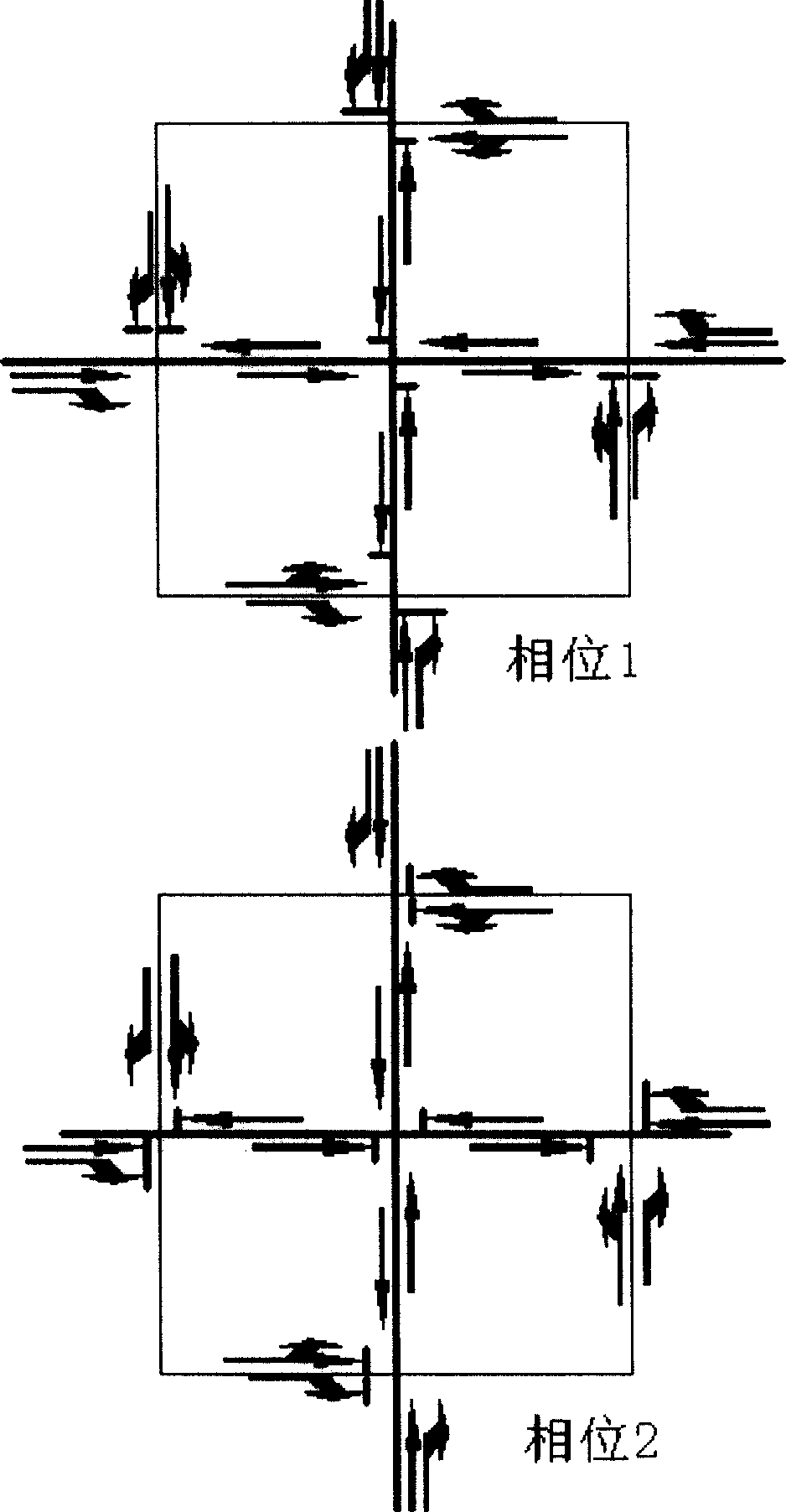

Novel traffic layout and control method for city road net and crossing

InactiveCN1766232AReduce the number of phasesRealize "green wave" controlRoad vehicles traffic controlTraffic signalsTravel modeSimulation

The invention discloses a traffic organization design and control improvement method of intersection passing capacity and road net traffic content in the traffic design and control domain, which is characterized by the following: adapting main road junction peripherial road net to form a micro-circulation system to finish steering task of each direction; adapting the ways such as í‹stop turning left or rightíŒ, í‹one way runningíŒ and so on to simplify the traffic intersection collision to improve the traffic intersection passing capacity; utilizing í‹green waveíŒ to reduce the parking frequency and driving delay. The program is fit for mutual matching of different grades, which realizes the city traffic harmonious development.

Owner:钱红波

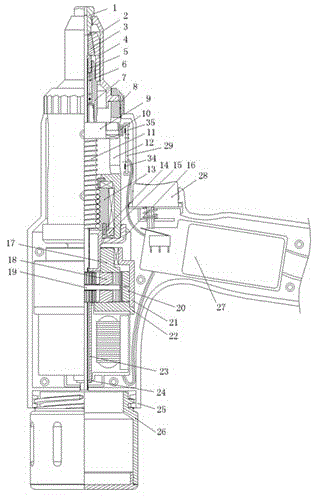

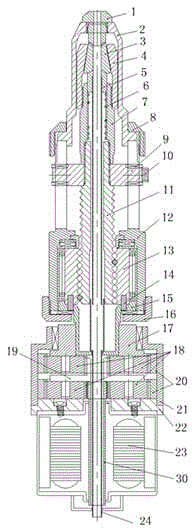

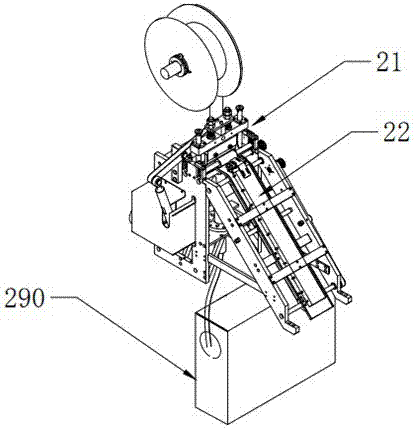

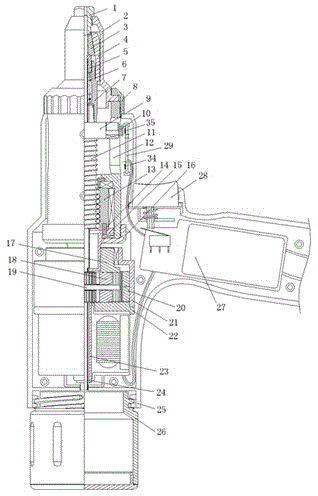

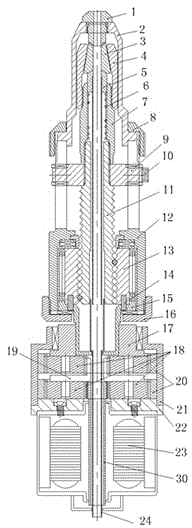

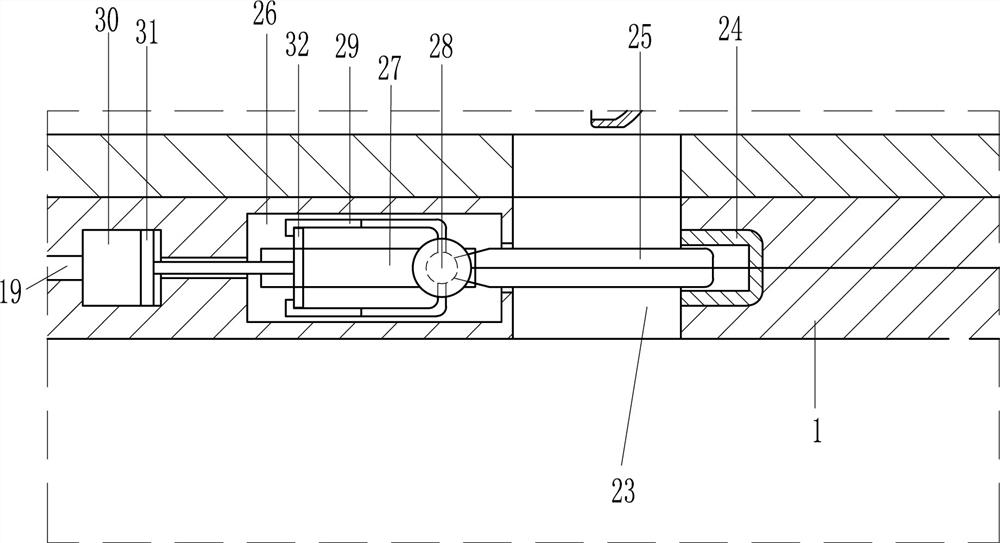

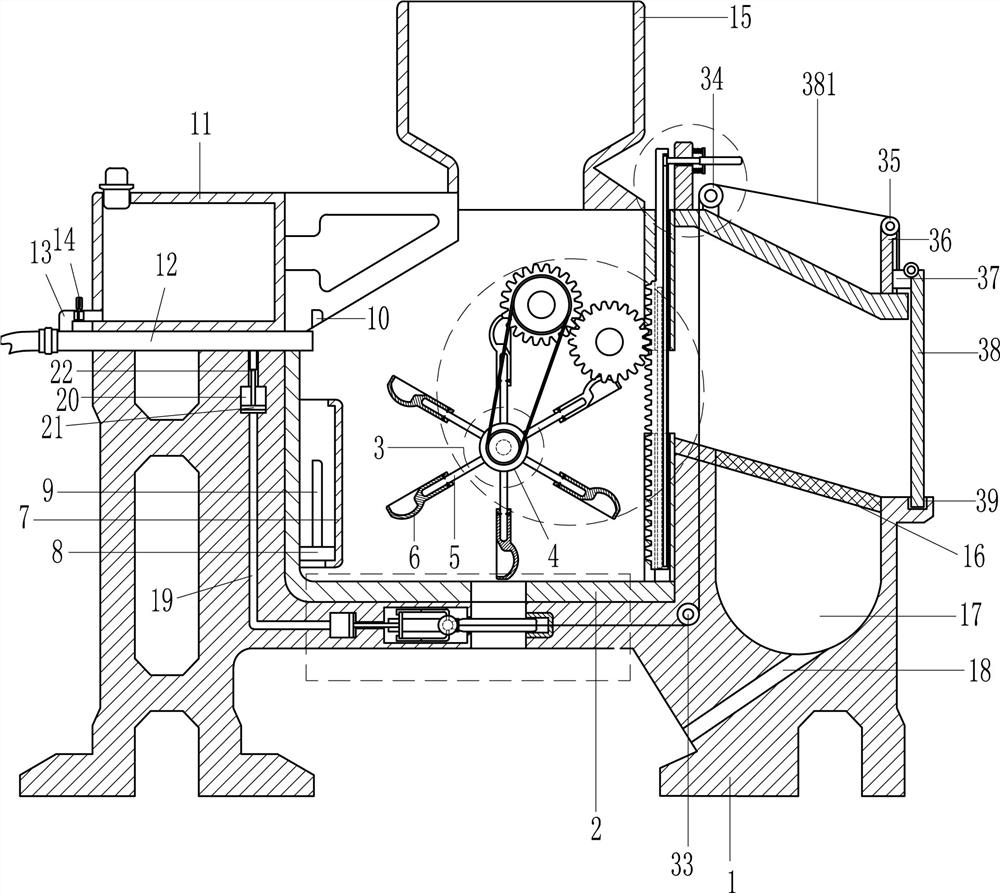

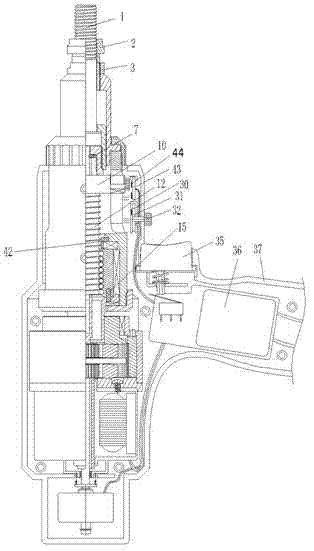

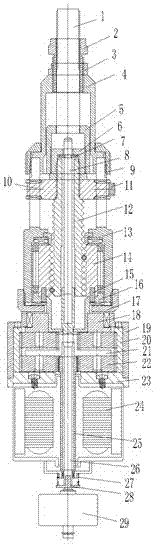

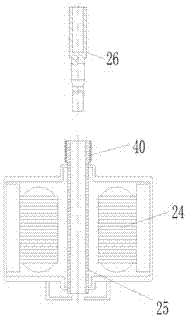

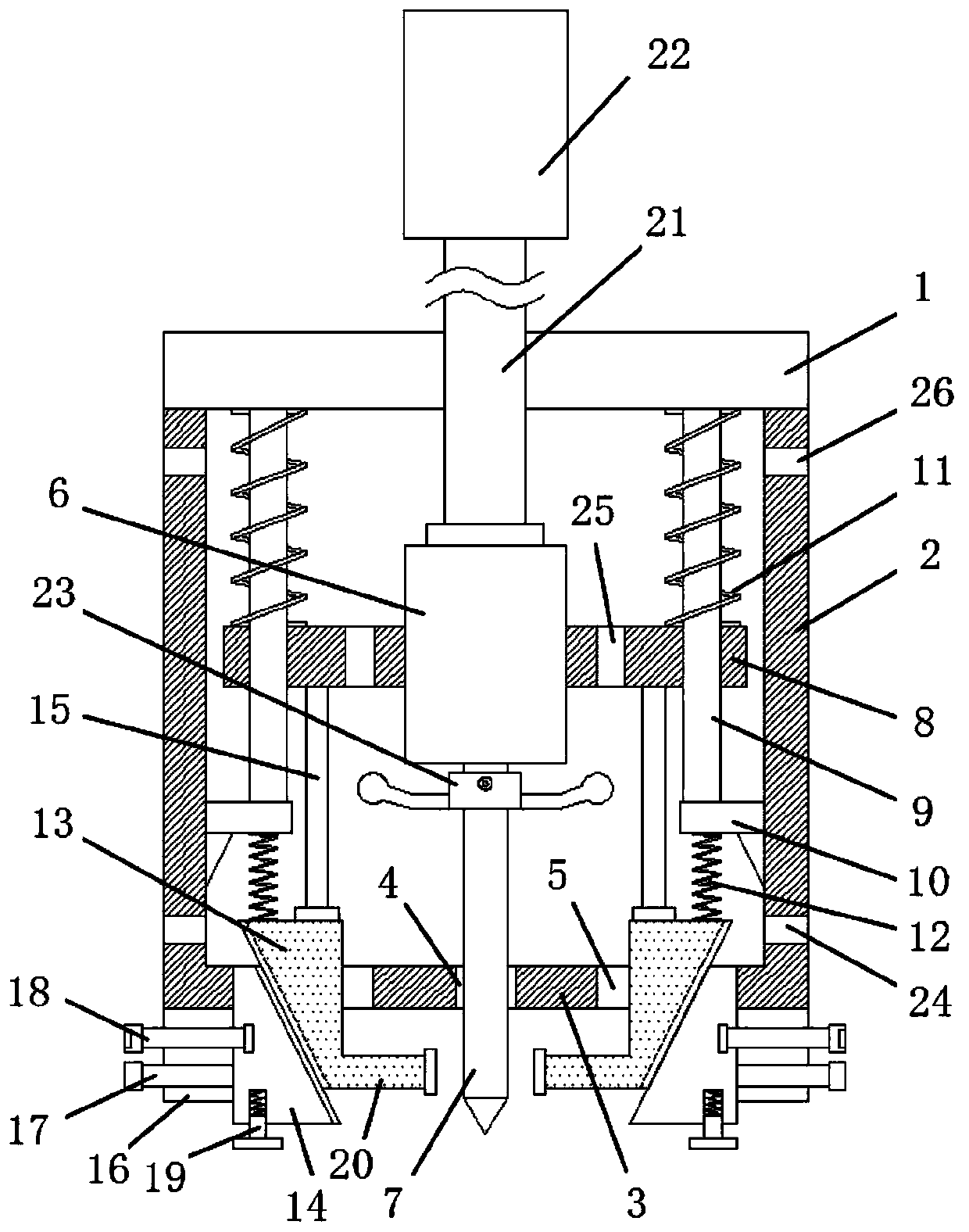

Electric riveting tool

ActiveCN104439022AUnlimited sizeImprove discharge effectToothed gearingsTransmission elementsControl lineInductor

The invention relates to an electric riveting tool used in the technical field of machines. The tool is composed of an outer cover, a trigger, a rivet pulling system, a lead screw transmission system, a planetary gear speed-reducing system and a power motor assembly. A spring sleeve is connected with the front end of a ball lead screw, the planetary gear speed-reducing system is fixed to a lead screw nut through a connection shaft, the power motor assembly is connected with the planetary gear speed-reducing system, a nail collecting cylinder is arranged at the rear end of the power motor assembly, a discharging pipe penetrates through a motor shaft and the planetary gear speed-reducing system and then is arranged outside a core ejector pipe in a sleeving mode, the outer cover is provided with a circuit board, the trigger and a stroke control plate, the circuit board is connected with a motor and the stroke control plate through control lines, the stroke control plate is provided with an inductor, a rolling wheel positioning block is provided with a magnet, and the inductor is located on the lower portion of the magnet. The tool is strong in power, can be used for work indoors and outdoors, is used in a handheld mode, accords with the principle of ergonomics, makes full use of tool space, can be used for pulling rivets of different specifications and is high in applicability, and waste nail rod discharging is easy.

Owner:昆山铆足劲工具有限公司

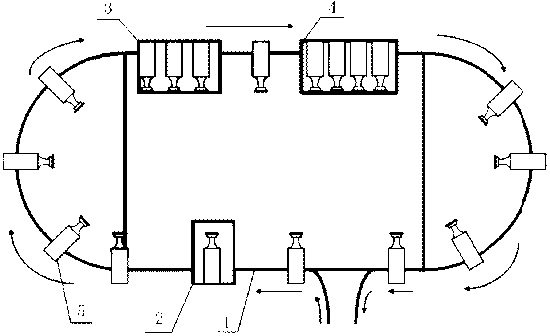

Online product quality detection device used on beer filling production line

ActiveCN103308113AAvoid interferenceAvoid complexityMaterial analysis using wave/particle radiationOptically investigating flaws/contaminationForeign matterProduction line

The invention discloses an online product quality detection device used on a beer filling production line. Three detection stations are located on a mechanical transmission device which is used for clamping and overturning beer bottles, wherein the detection station I comprises one or two cameras I for photographing upright beer bottles and a backlight source I and is mainly used for detecting liquid levels and floaters; the detection station II comprises cameras II for photographing the neck and body areas of inverted beer bottles and a backlight source II and is mainly used for detecting suspended matters and part of deposits; and the detection station III comprises an X-ray imaging device for detecting the cap areas of the inverted beer bottles and is mainly used for detecting foreign matters and deposits. The online product quality detection device has the advantages of high detection speed and low missing detection rate.

Owner:SHANDONG MINGJIA TECH

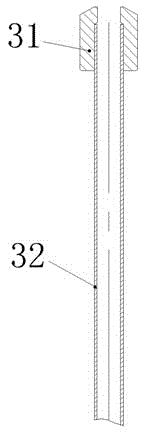

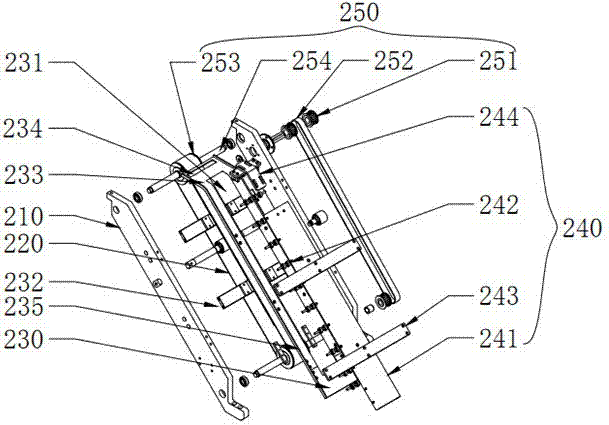

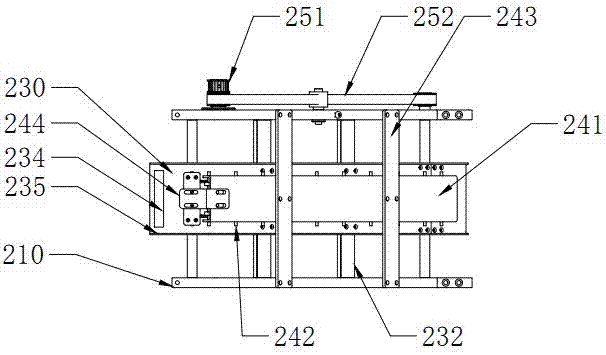

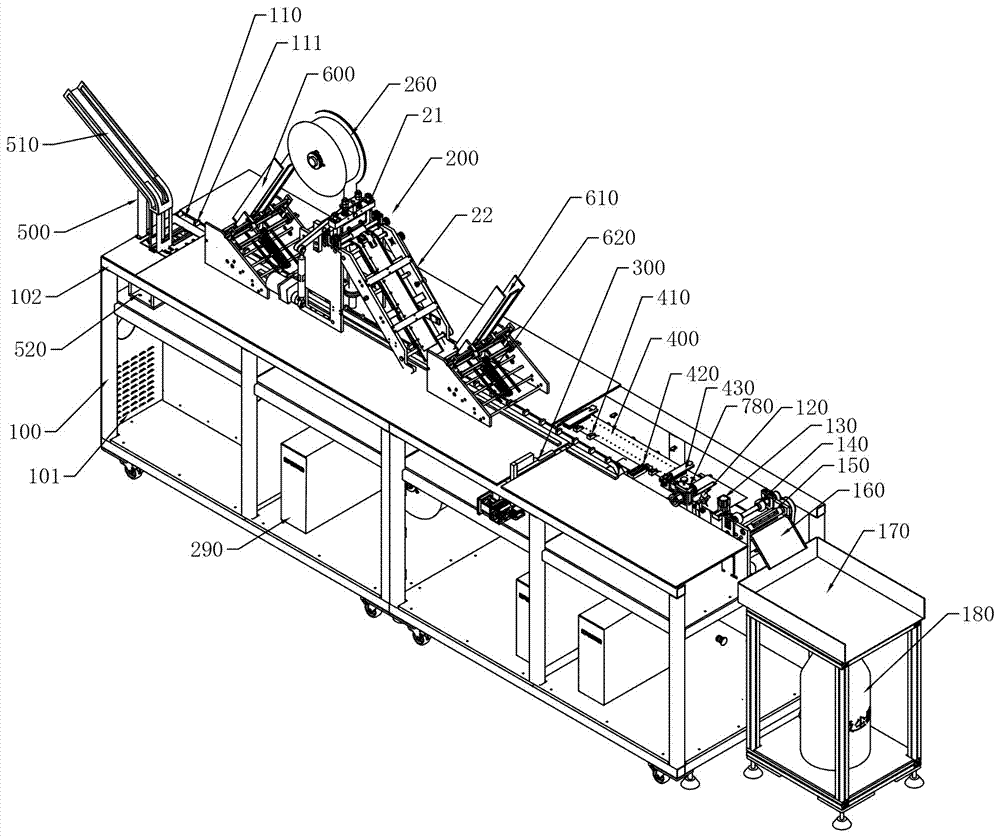

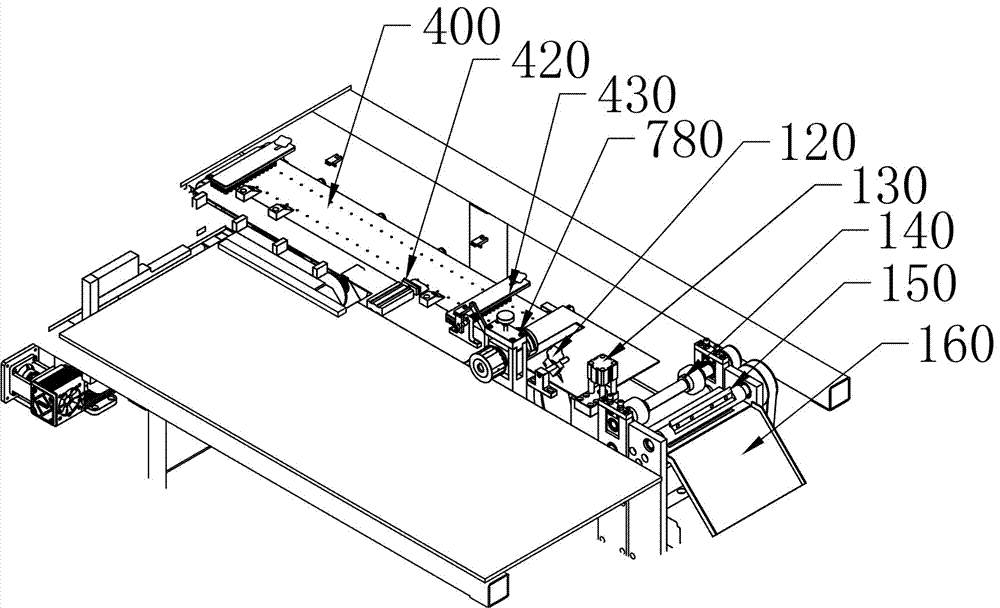

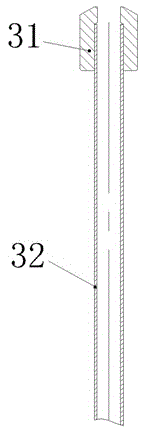

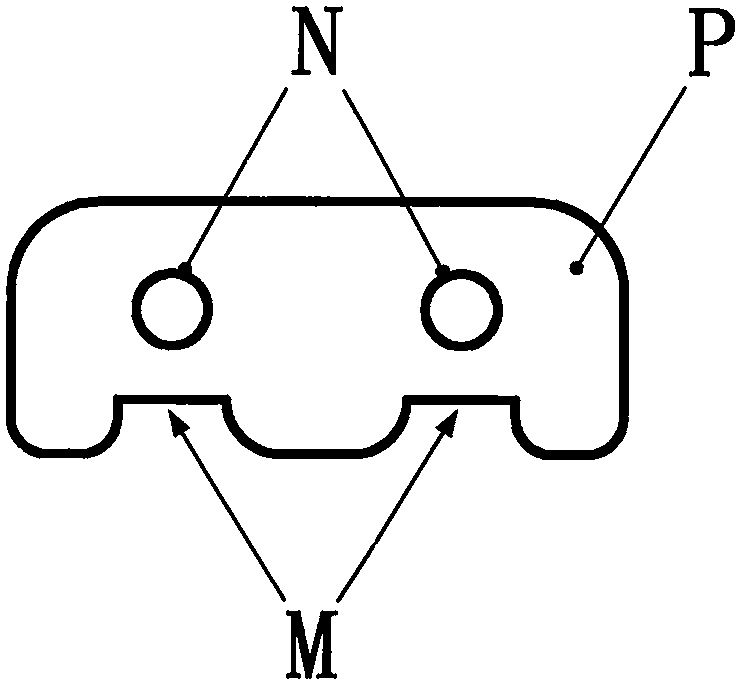

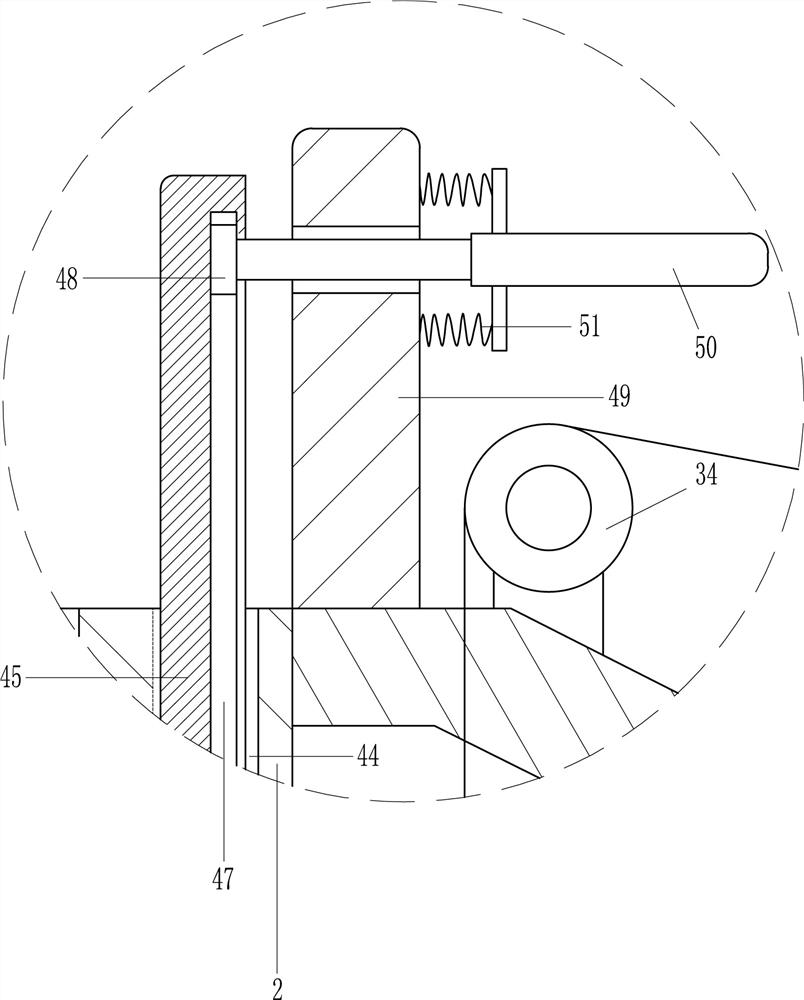

Cloth cutting and conveying device and multi-type packaging integrated machine

PendingCN107244464AGuaranteed smoothGuaranteed accuracySevering textilesWrapper twisting/gatheringTransmission beltDrive shaft

The invention relates to a cloth cutting and conveying device which comprises a cutting part and a conveying part. The conveying part comprises supporting frames on the two sides, a conveying belt with the width smaller than the cloth width, a conveying plate and a compression component arranged above the conveying belt; the supporting frames are connected with the cutting part; the conveying belt is connected with a driving component through a belt wheel and a transmission shaft; the conveying plate is erected on the supporting frames through supporting rods, a groove matched with the conveying belt is formed in the middle, the conveying belt is installed at the position of the groove, and the surface of the conveying belt is aligned at the surface of the conveying plate; the transmission shaft and the compression component are both erected on the supporting frames; and the cutting part conveys cut cloth to the conveying plate through a traction roller. The cloth cutting and conveying device does not become warped and roll edges in the cloth conveying process, smoothness of single cloth is guaranteed, back rolling does not occur in the tail of the conveying belt, the conveying accuracy is guaranteed, the cloth cutting and conveying device is suitable for conveying of cloth with different widths and different thicknesses, and the cloth cutting and conveying device is particularly suitable for packing machines for packaging the cloth.

Owner:广州米贺智能科技有限公司

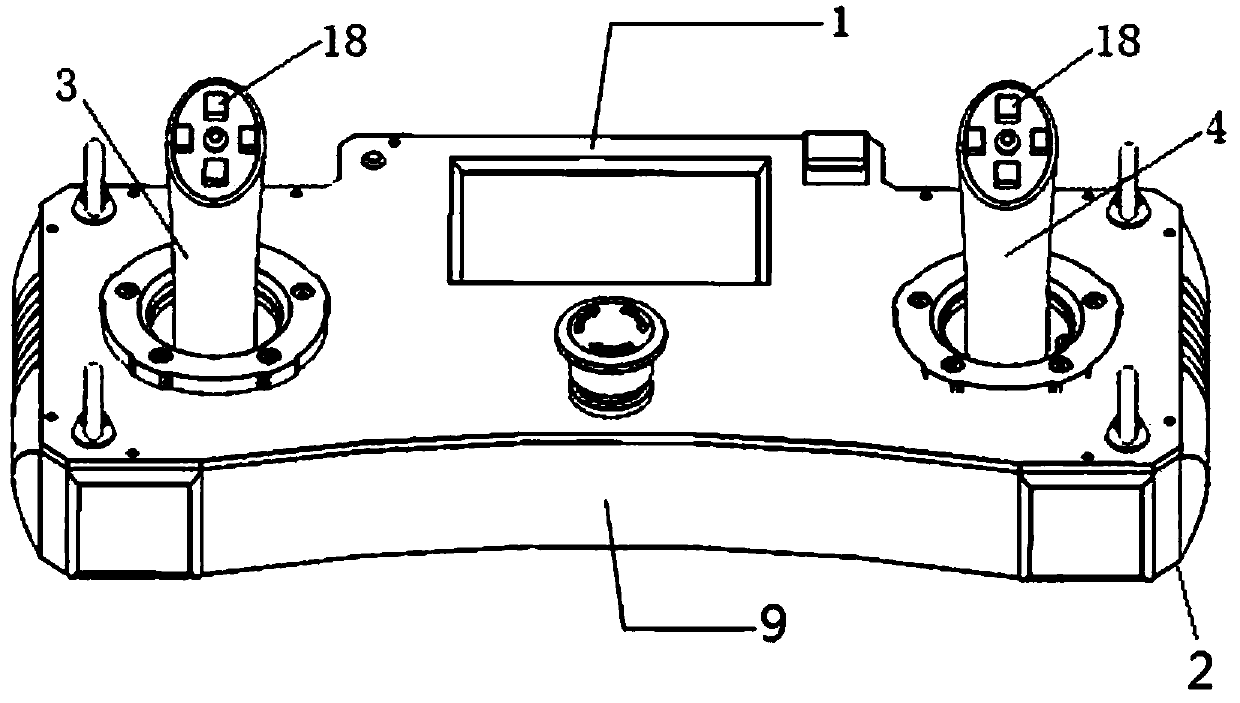

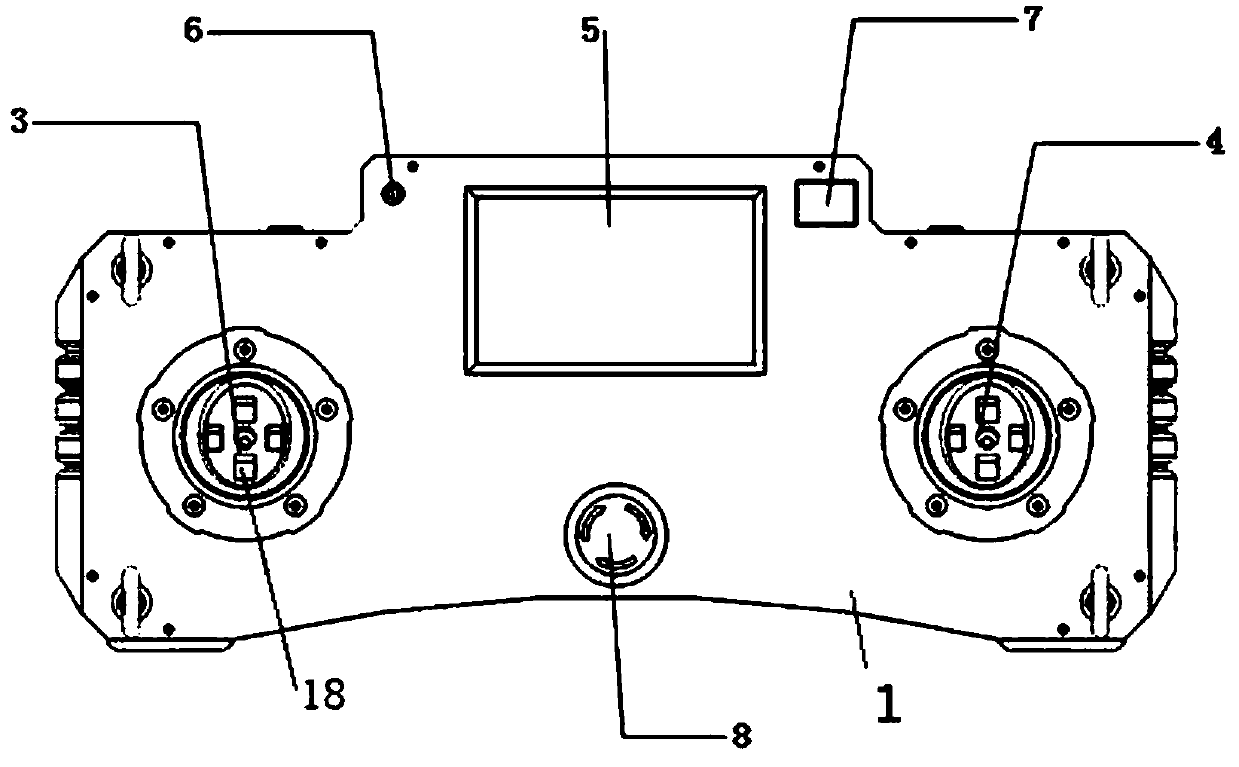

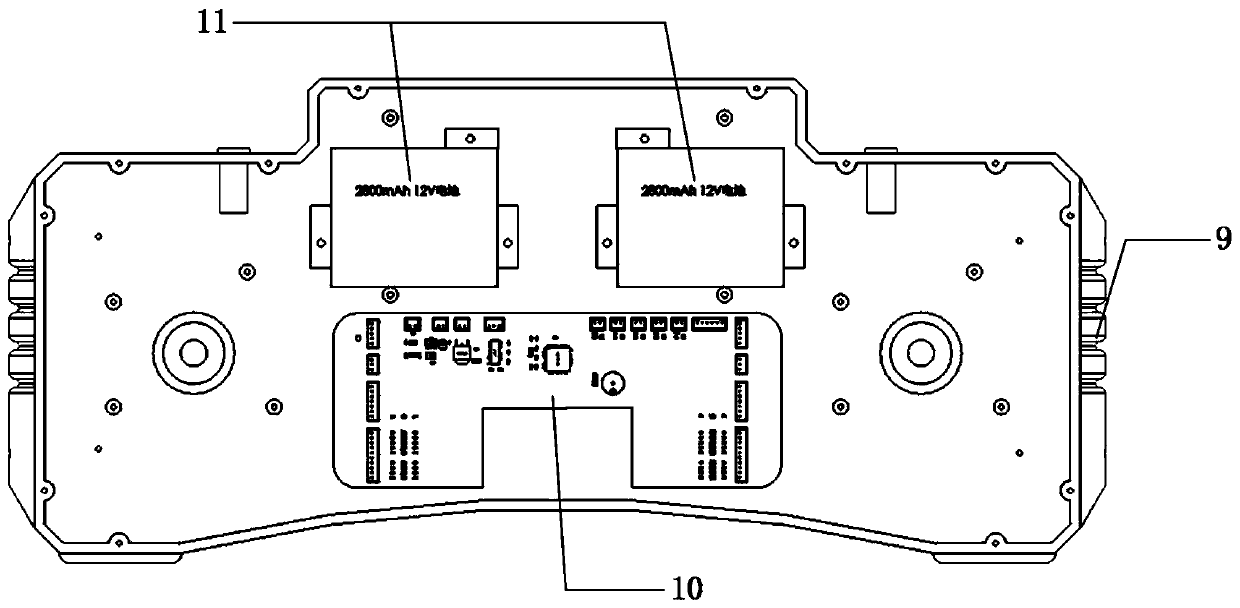

Remote controller for high-maneuverability ground unmanned platform and remote control method thereof

ActiveCN110390810AReasonable division of laborImprove work efficiencyTransmission systemsElectric switchesMarine engineeringAttitude control

The invention discloses a remote controller for a high-maneuverability ground unmanned platform and a remote control method thereof. The remote controller comprises a whole machine composed of a casing and a remote control panel, wherein the remote control panel is provided with a left and right handles, a power switch and an emergency stop switch; the left and right handles each have a horizontalmotion dimensionality, a vertical motion dimensionality and a rotation motion dimensionality; the left and right handles each have a plurality of composite control buttons; the combination of the left handle and the plurality of composite control buttons achieves the operation control of walking, turning, lighting and horn of the unmanned platform; the combination of the right handle and the plurality of composite control buttons achieves the attitude control of the unmanned platform. The remote controller has reasonable layout, high reliability, good universality, good intellectualization, good human-machine interaction, and is easy to operate, easy to maintain and wide in application range.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Intermediate track and auxiliary device transportation system

ActiveCN102190005AReduce angle of attackReduce track vibration and noiseTrack-braking member co-operationMiddle lineTransit system

The invention discloses an intermediate track and auxiliary device transportation system, which belongs to the technical field of wheeltrack railways and can effectively solve the problems of transverse force, vertical force, starting friction force, braking operation resistance and climbing friction force in the transportation process of a train. In the technical scheme, an intermediate track is established on a median line between a left steel rail and a right steel rail of the conventional wheeltrack railway; a controller device is arranged on the middle lower side of a train bogie wheel shaft or a cross beam; the lower end of the controller device is vertically connected with a hanger device, and the upper end of the controller device is provided with a damping device; a lifting frame wheel shaft which is arranged on the middle upper side of the intermediate track and is extended from a bogie pulling motor rotating shaft gear and a bogie wheel shaft gear is provided with a starting wheel, a braking wheel 1 and a braking wheel 2; and a brake caliper device is arranged in front of the starting wheel or the braking wheel 2 or behind the braking wheel 1. The technical scheme has extremely prominent effects of improving the safety, the speed and the benefit of the train during operation, preventing the wheel / track from abrasion, and the like.

Owner:张发林

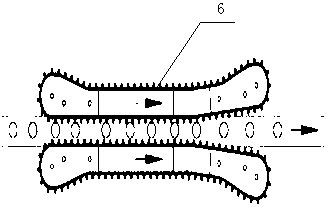

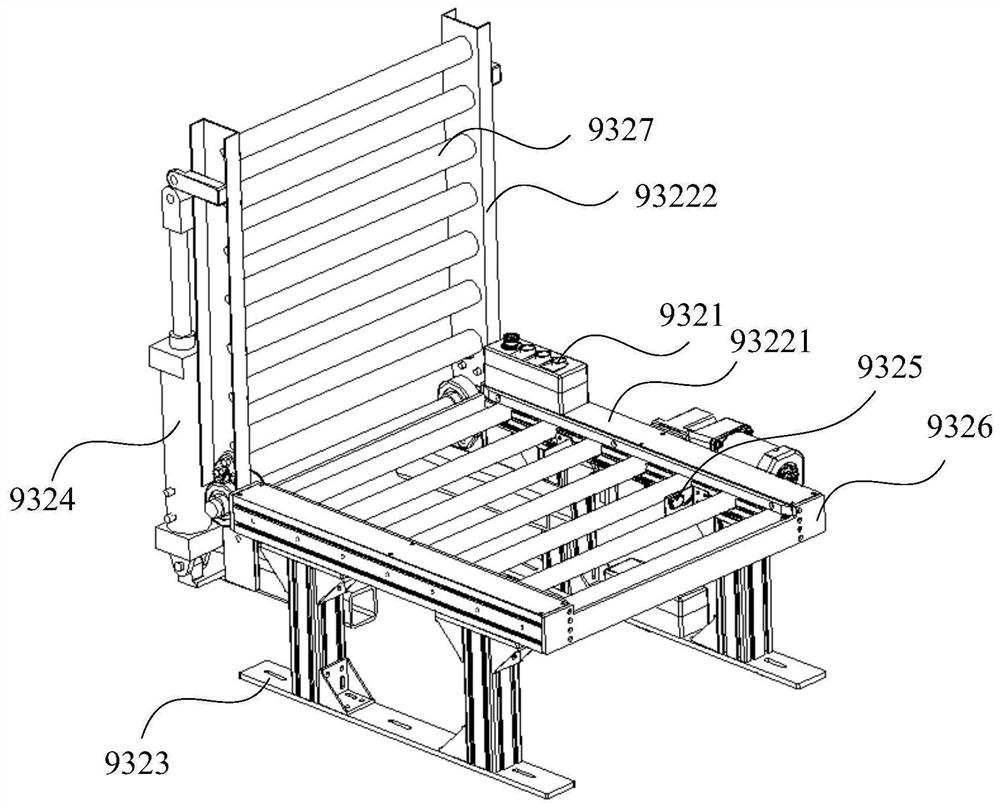

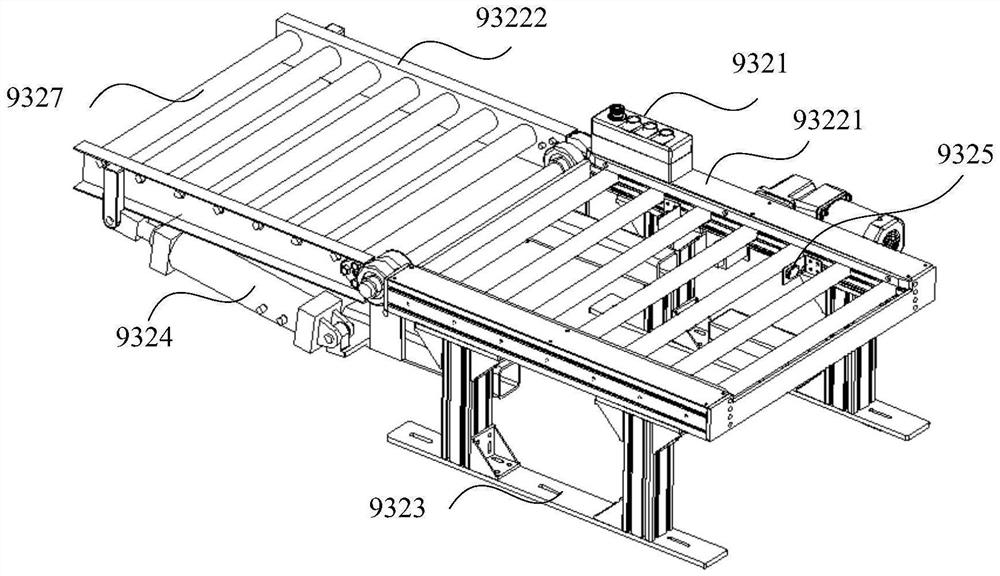

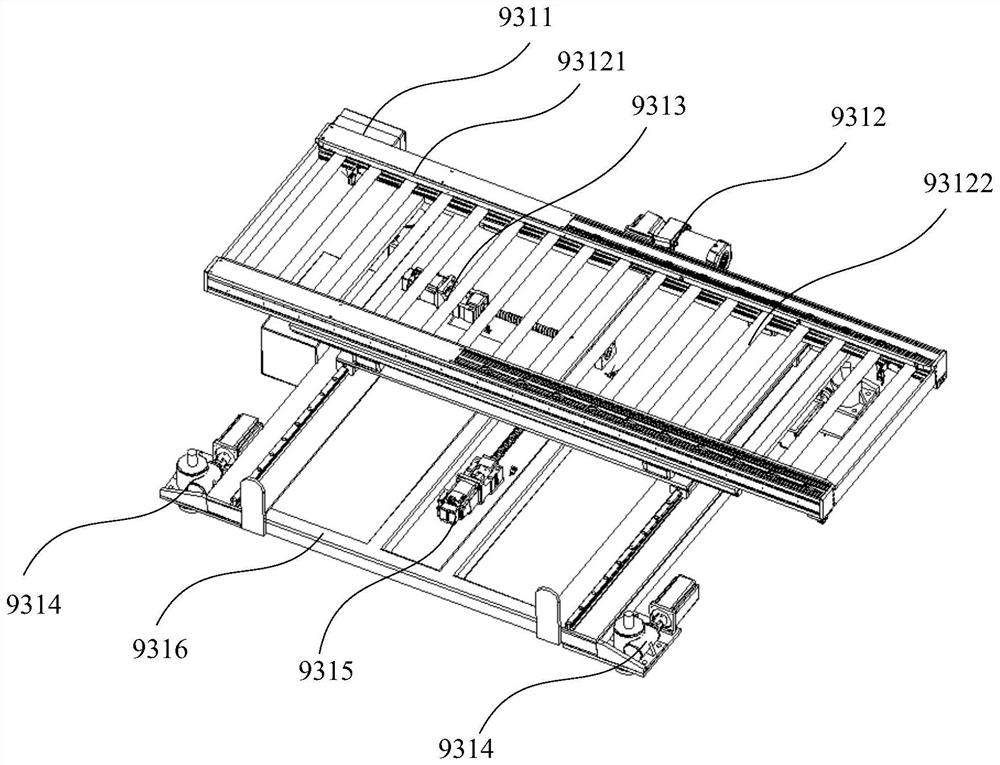

Platform conveying system, vehicle door conveying system and rail transit joint control conveying system

PendingCN114261799ARealize automatic transmissionImprove transport efficiencyLoading/unloadingStorage devicesLogistics managementControl engineering

According to the platform conveying system, the vehicle door conveying system and the rail transit joint control conveying system, the platform conveying system is arranged on a platform, the vehicle door conveying system is arranged on a rail vehicle, and a master control device is connected with the platform conveying system and the vehicle door conveying system so that the platform conveying system and the vehicle door conveying system can be in butt joint. Goods are conveyed on the platform and the rail vehicle, automatic conveying of the goods on the rail vehicle and the platform is achieved, meanwhile, reasonable labor division and effective connection can be conducted, the goods transfer efficiency is improved, and a foundation is laid for building of a comprehensive traffic transportation system. The position adjusting assembly drives the platform conveying assembly to conduct spatial position adjustment, so that the platform conveying assembly and the vehicle door conveying system can be in butt joint, the butt joint efficiency and the conveying efficiency are further improved, manual operation is reduced, intelligent development of the rail transit joint control conveying system is achieved, and the modern logistics development requirement is met.

Owner:CRRC TANGSHAN CO LTD +1

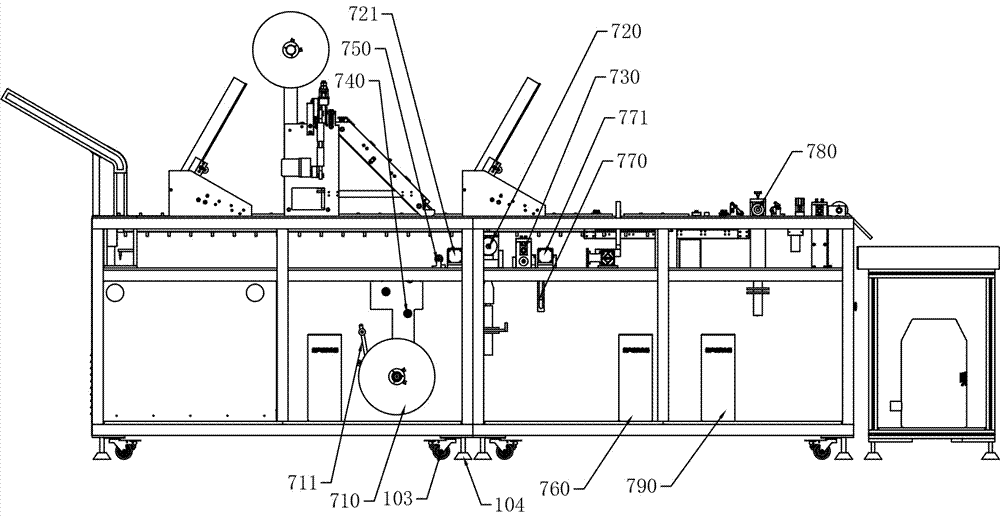

Multi-type packaging integrated machine and packaging method thereof

PendingCN107284777ASimplify the packaging processImprove adjustabilitySevering textilesWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a multi-type packaging integrated machine which comprises a machine frame and a conveying belt. A plurality of limiting parts connected in sequence are fixedly installed on the conveying belt. A limiting groove is formed between every two adjacent limiting parts. The machine frame comprises a lower layer, a middle layer and an upper layer. The upper layer of the machine frame is provided with a material dispensing device, a material pushing device and a packaging device which are sequentially connected. The material dispensing device comprises a cloth cutting and conveying device. The material pushing device comprises a linear pushing module and a vacuum conveying belt. The linear pushing module and the vacuum conveying belt are arranged on the two sides of the conveying belt correspondingly, and the pushing direction of the linear pushing module is opposite to the opening direction of a packaging film. Compared with the prior art, the multi-type packaging integrated machine in the scheme has the beneficial effects of being capable of achieving packaging easily, good in adjustability, high in packaging speed and applicable to packaging of various packaging films and materials.

Owner:广州米贺智能科技有限公司

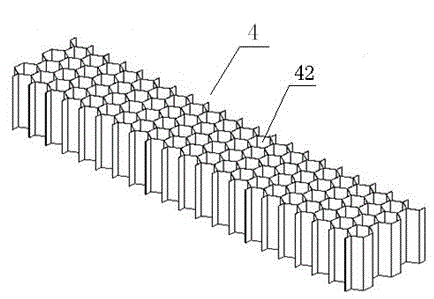

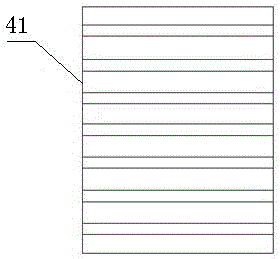

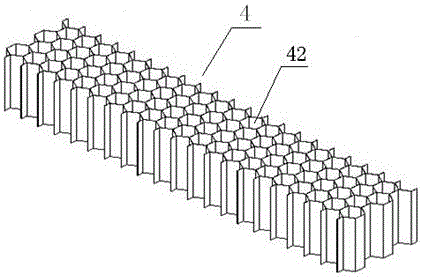

Welding method for air purifier honeycomb mesh

ActiveCN104907658AImprove efficiencyReasonable division of laborWelding/cutting auxillary devicesAuxillary welding devicesScreen printingManufacturing cost reduction

The invention relates to a welding method for an air purifier honeycomb mesh. The welding method comprises the following steps: I, cleaning zinc coated sheets: removing impurities from the surfaces of the zinc coated sheets which are continuously bent positively and negatively in a trapezoidal way; II, performing screen printing of soldering paste: performing screen printing of soldering paste on the joint faces of the zinc coated sheets which are continuously bent positively and negatively in a trapezoidal way through a silk screen, wherein screen printing is performed at three positions on each joint face; III, assembling the honeycomb mesh: putting the zinc coated sheets which are screen-printed with the soldering paste into a honeycomb mesh welding fixture one by one and clamping, thereby constructing the air purifier honeycomb mesh with a plurality of hexagonal holes; IV, heating and welding: putting the air purifier honeycomb mesh and the honeycomb mesh welding fixture into a drying oven for heating till the soldering paste is molten, welding, discharging and performing air cooling to the room temperature; V, loosening the honeycomb mesh welding fixture, and taking the air purifier honeycomb mesh out to obtain a finished product. The production efficiency can be increased greatly, a clad layer close to a welding spot is protected from being damaged, the product quality is enhanced, and the manufacturing cost is lowered.

Owner:SOUTHWEST COMP

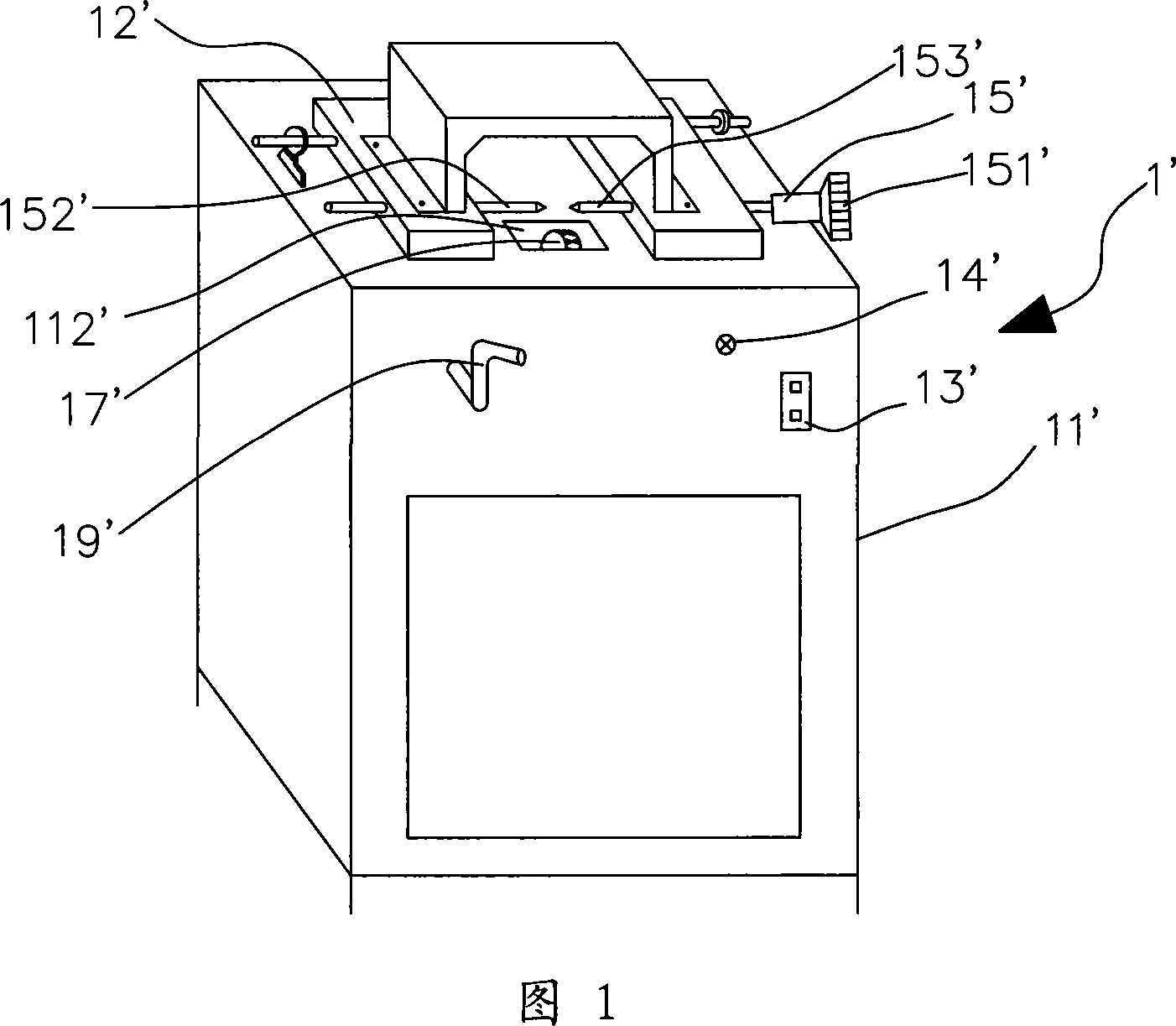

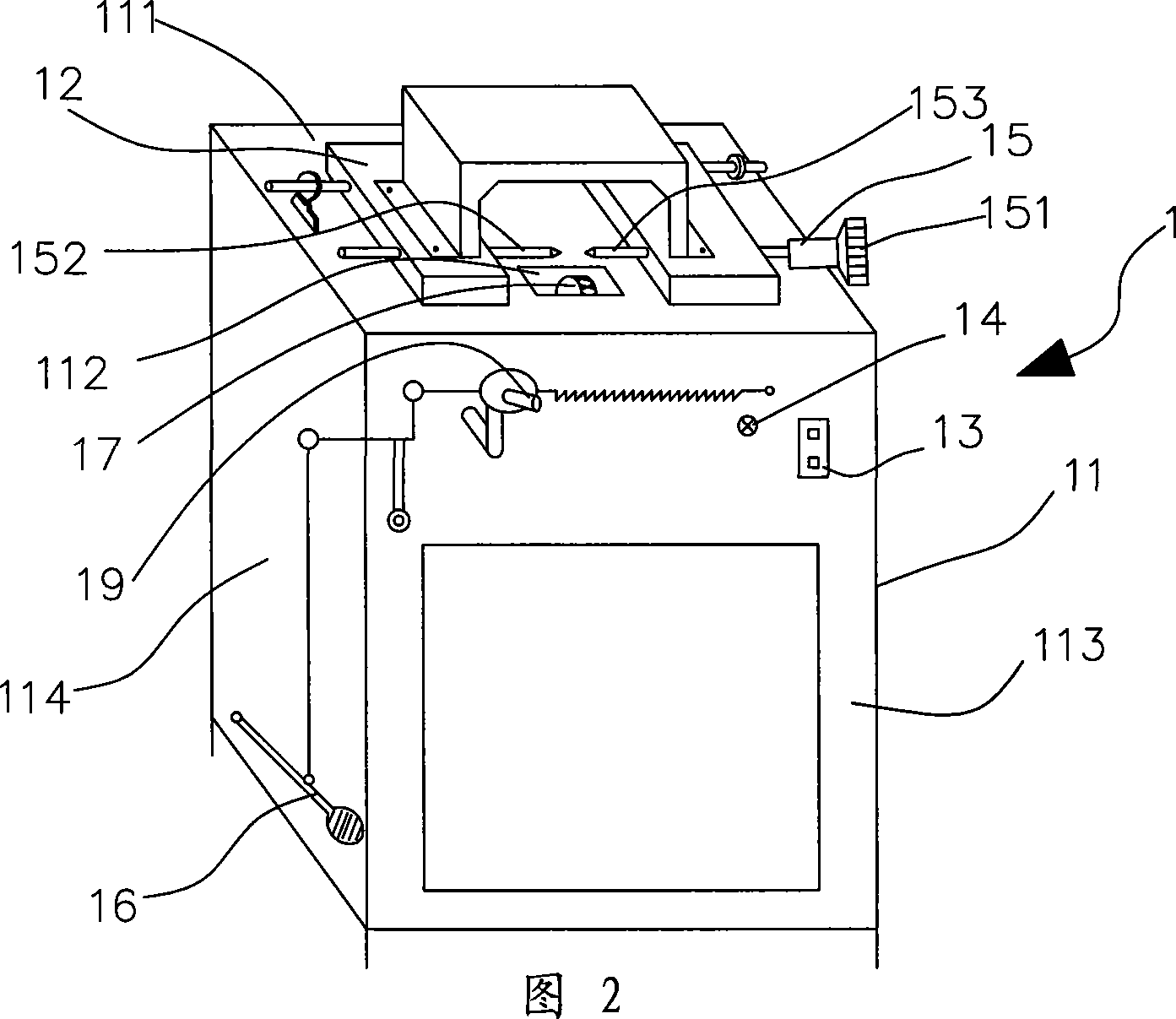

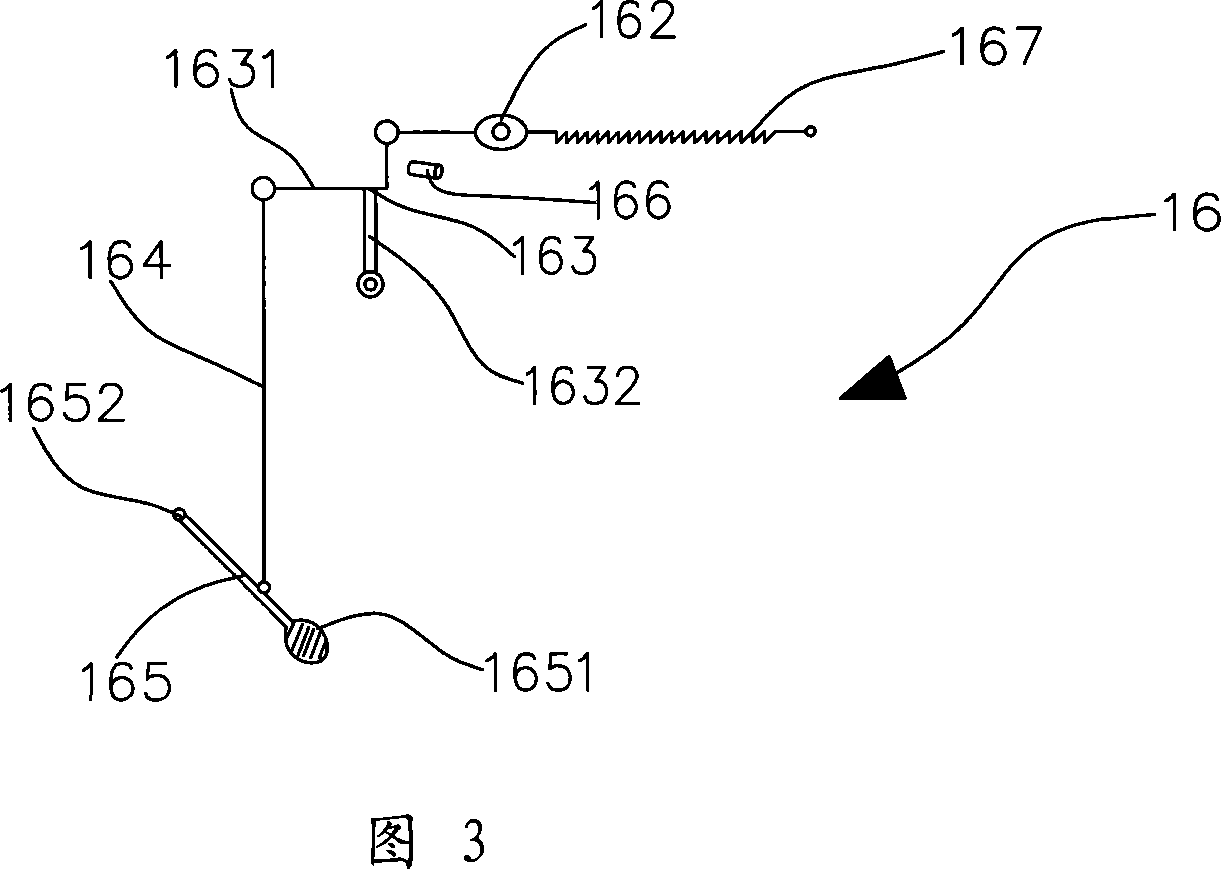

Pedal control gem shaping machine

The pedal control marble positioning machine comprises the base, sand wheel, locomotive, locomotive alight operation lever and back and forth structure. It also comprises the tumbler device that is composed of tumbler plate, return spring connected to one side of the tumbler plate, motor directing machine connected to the end side of the tumbler plate, pedal fixed to the bottom of the base, pulling line connected to the motor directing machine and the pedal and the return controller, locomotive alighting operation bar installed inside the central hole, return spring not fixed to the base with the tumbler plate, nor of the drive directing machine and the tumbler plate. It is simple in process, operation and low in cost, with reasonable distribution, safe operation, reduced operation time, production cost and improved working efficiency and economical returns with ensured production quality.

Owner:何伟坚 +3

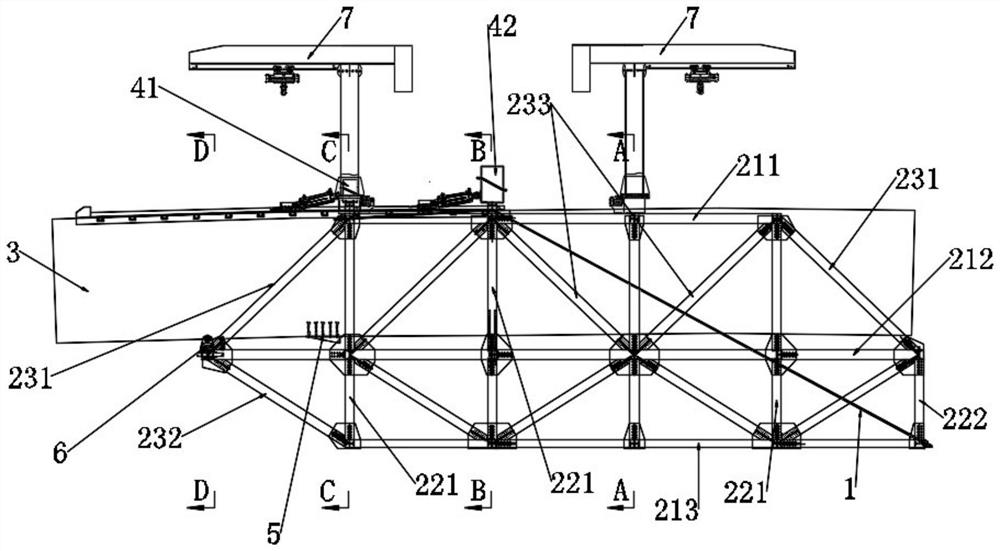

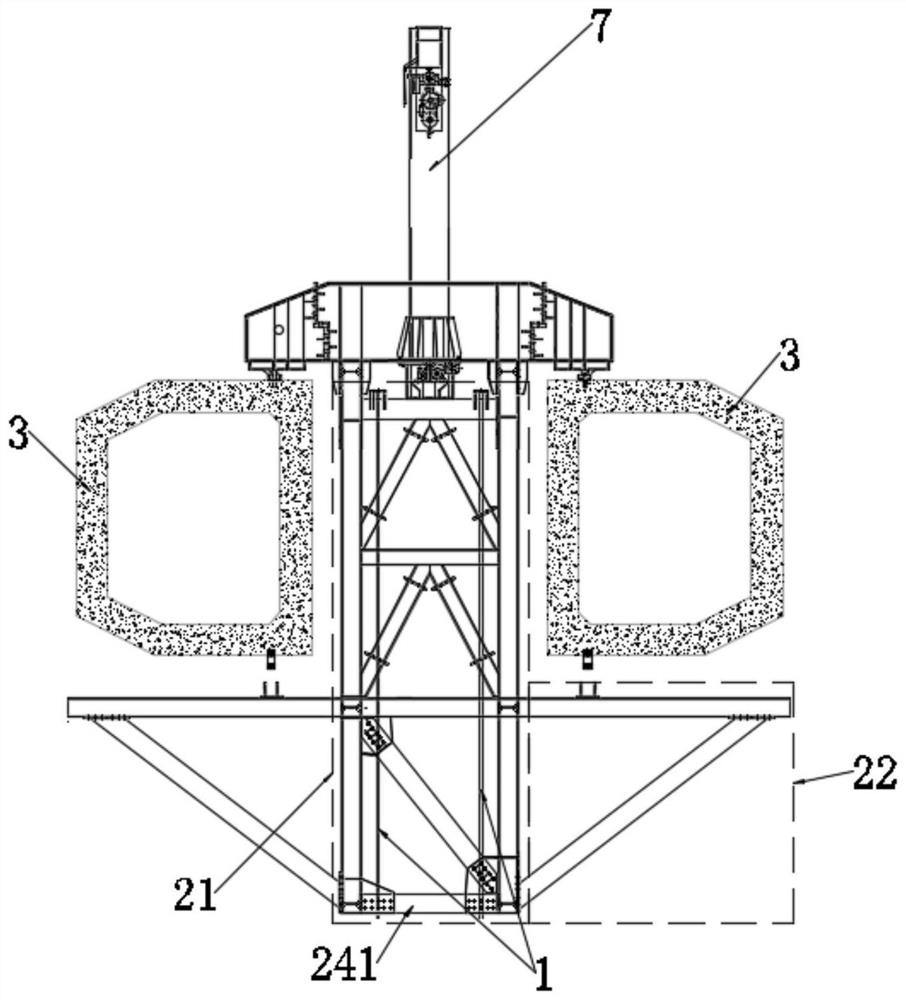

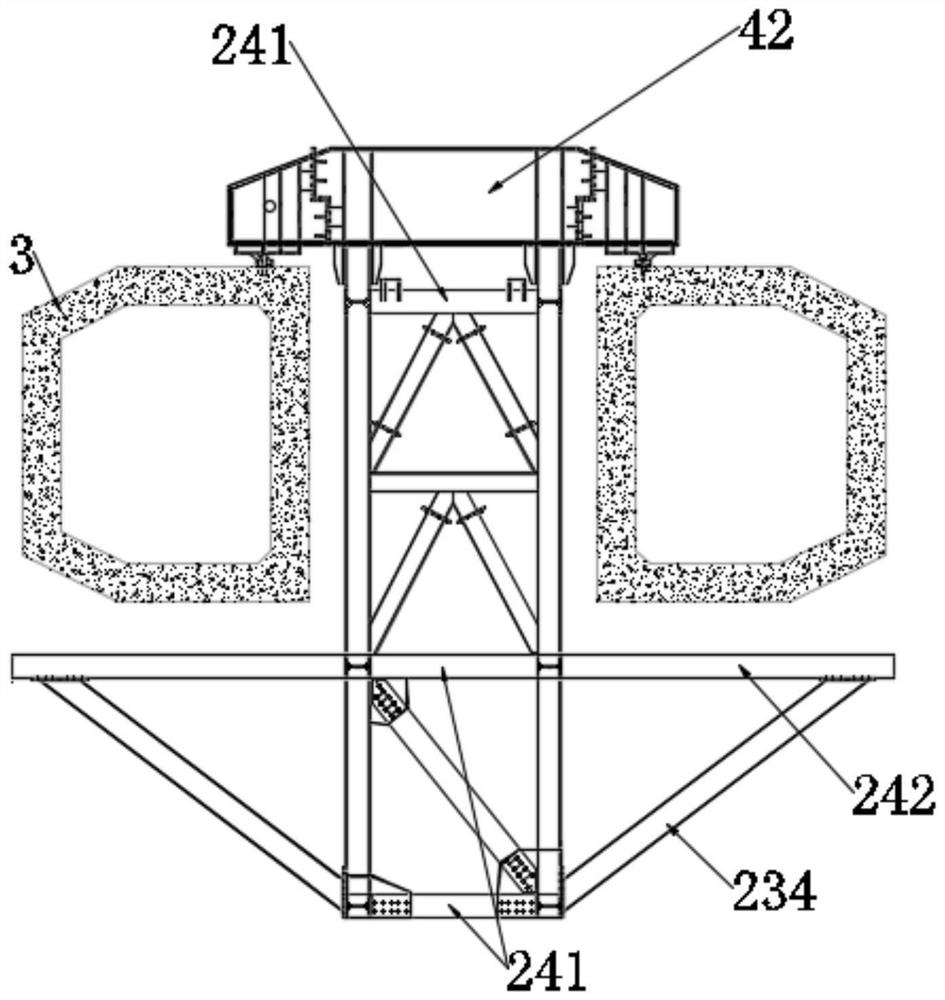

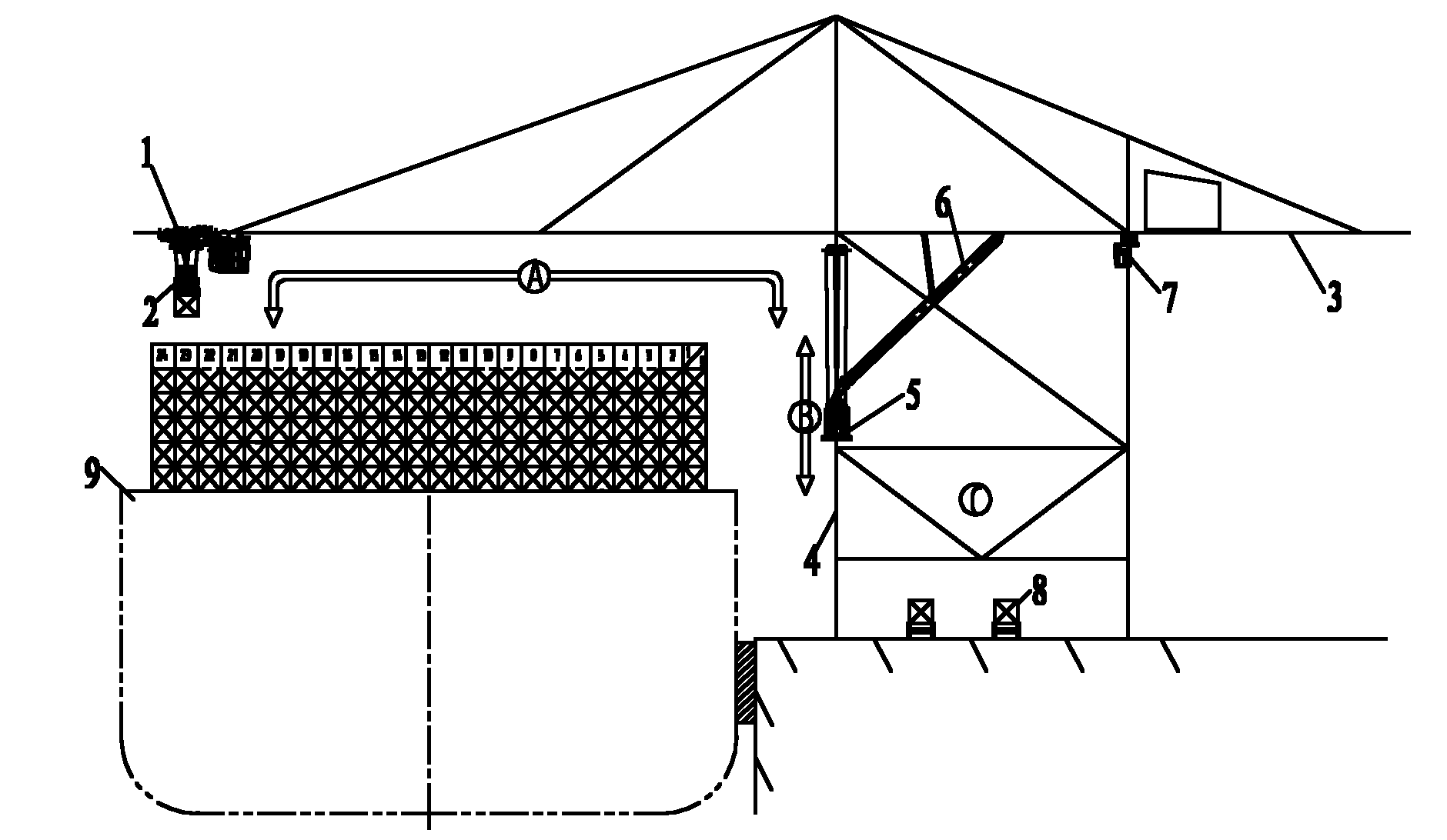

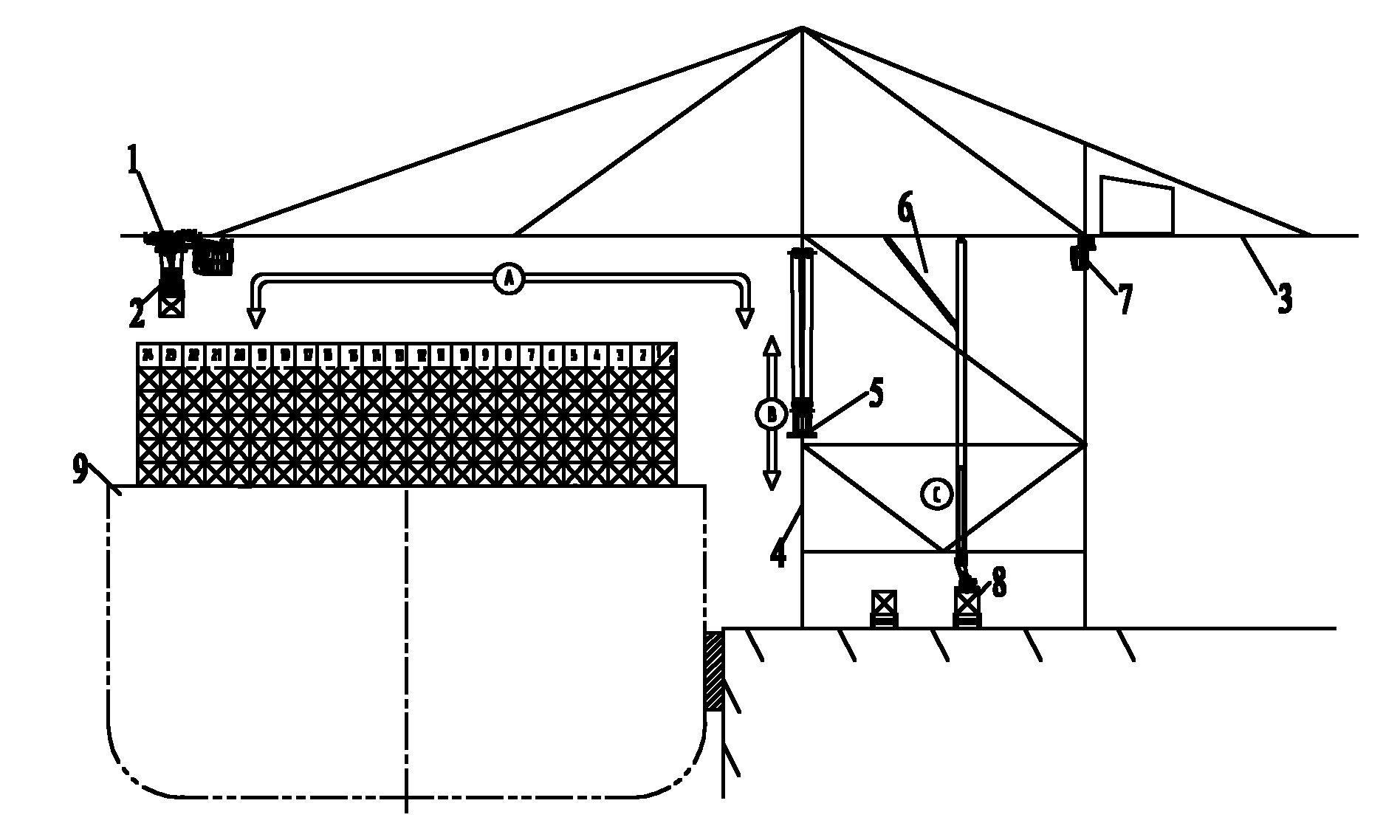

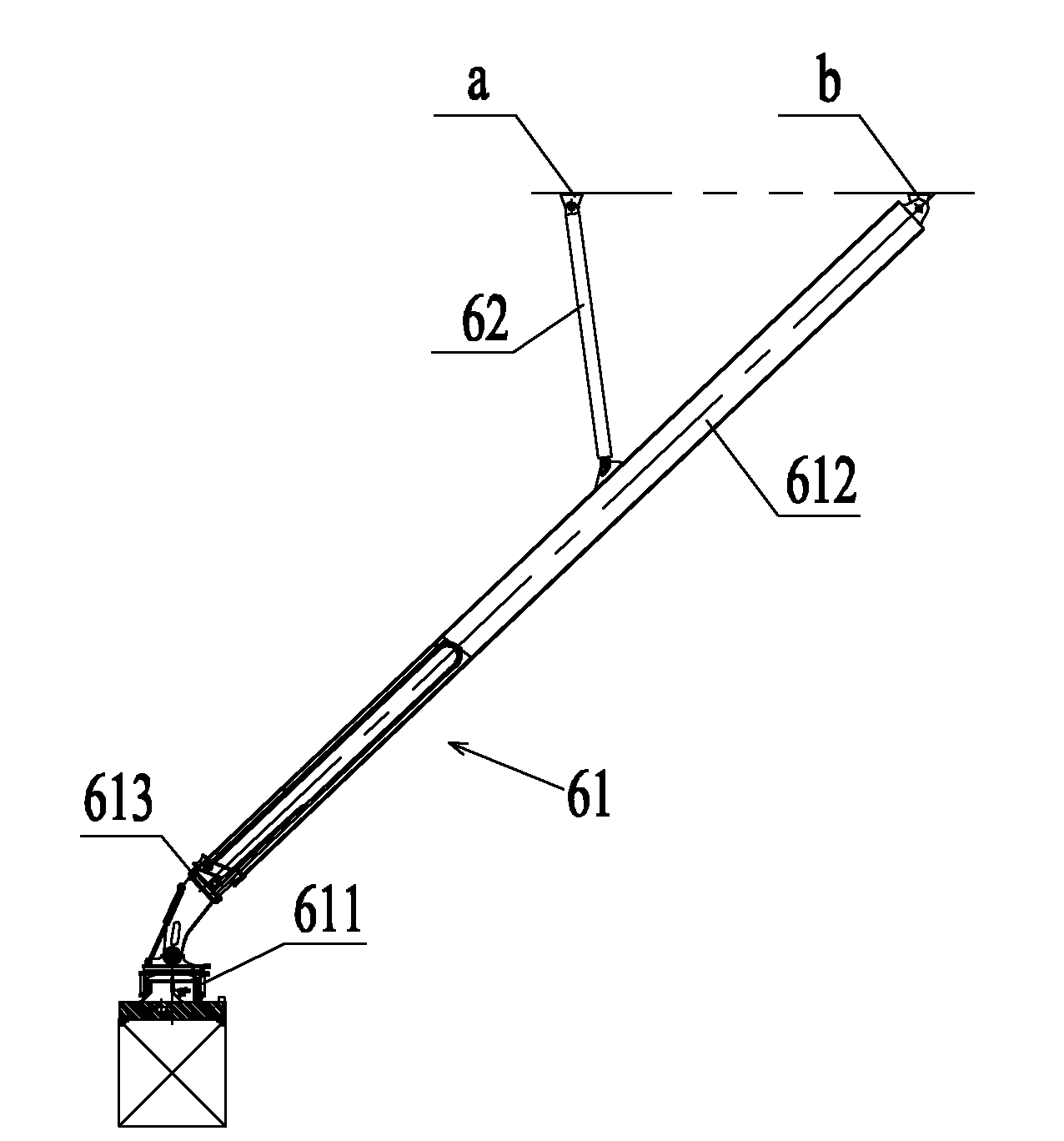

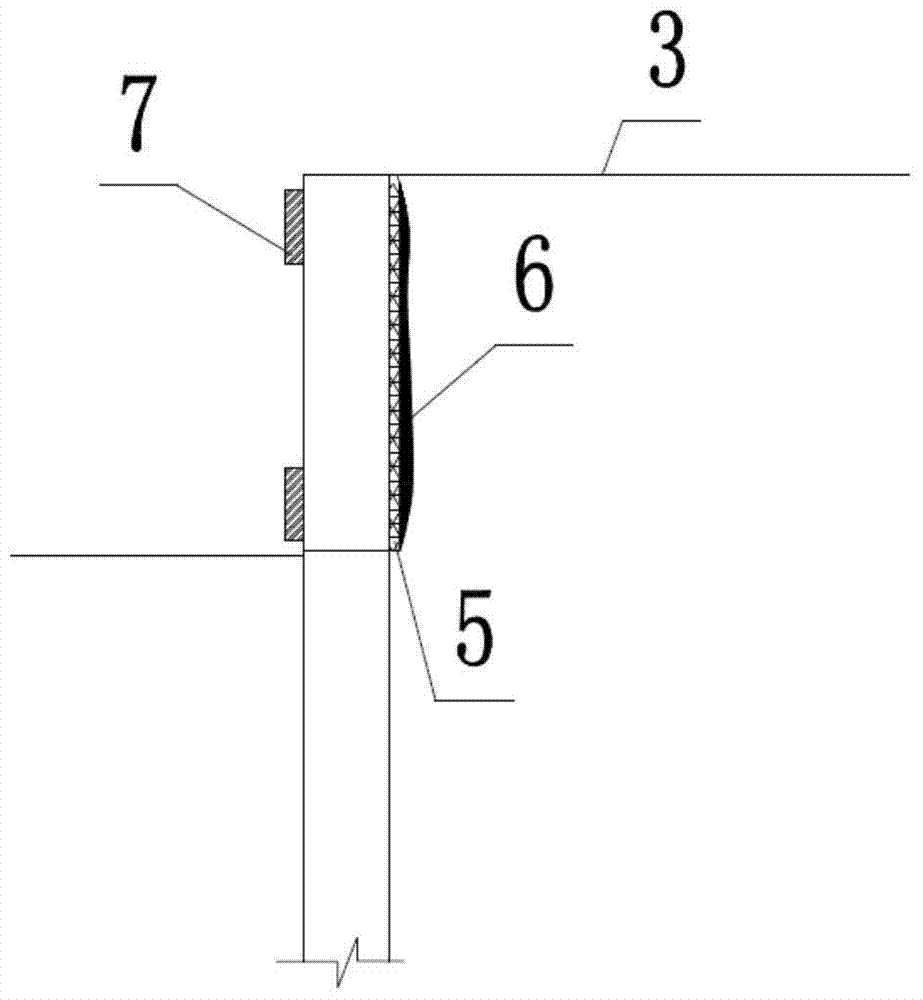

Hanging basket structure

ActiveCN114164773ALight weightEasy constructionClimate change adaptationBridge erection/assemblyArchitectural engineeringHanging basket

The invention relates to a hanging basket structure which comprises a truss bearing system, a walking system, a reaction force bearing system and a thrust system, the walking system, the reaction force bearing system and the thrust system are all installed on the truss bearing system, the hanging basket structure further comprises at least two prestressed cables, and all the prestressed cables are distributed at intervals in the transverse direction of the truss bearing system. One end of the prestressed cable is connected with the top of the longitudinal rear half part of the truss bearing system, and the other end of the prestressed cable is connected with the bottom of the longitudinal front end of the truss bearing system. At least two prestressed cables are arranged between the longitudinal rear half part and the longitudinal front end of the truss bearing system, so that the longitudinal front end of the hanging basket can be pulled up by taking the top of the longitudinal rear half part of the truss bearing system as a fulcrum, the use balance of the hanging basket structure can be improved, the longitudinal length of the hanging basket structure is increased, and the service life of the hanging basket structure is prolonged. The dead weight of the hanging basket structure is reduced as much as possible, so that the hanging basket structure is convenient to construct, and the cost is reduced.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

Design method for non-reversible hidden engineering embedding

InactiveCN101100874ANovel ideaImprove the quality of workBuilding constructionsShop drawingComputer science

This is a design method for built-in fittings of non-reversible concealed work. Because of the non-reversible character of built-in fittings, a specific design on the fittings among every area are collectively marked and compiled on the layout. The design contents include general description of construction, cutline, ichnography, serial number table and detail drawings.

Owner:姚军

Electric Rivet Tool

ActiveCN104439022BUnlimited sizeImprove discharge effectToothed gearingsTransmission elementsControl lineInductor

Owner:昆山铆足劲工具有限公司

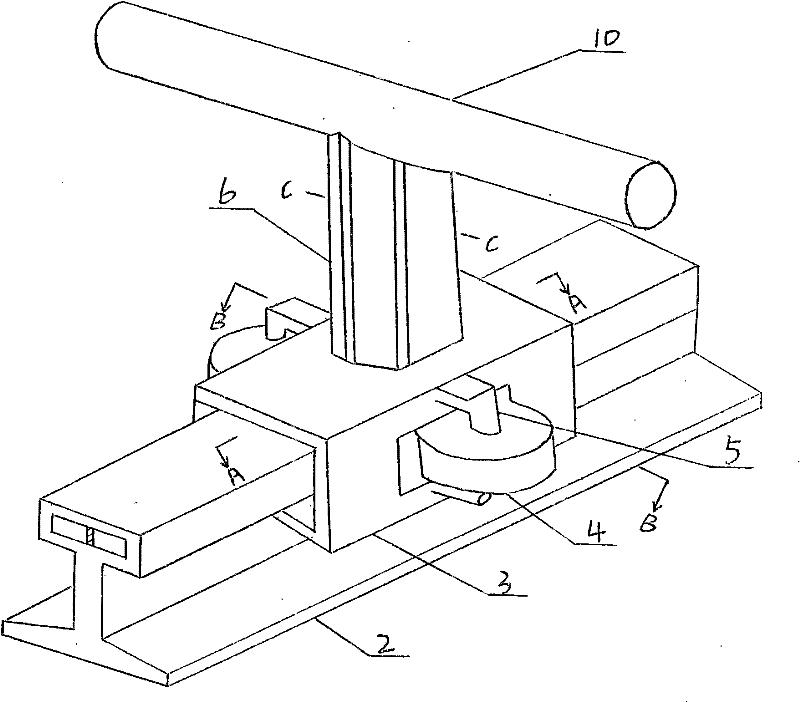

Container crane

InactiveCN102173365AEasy loading and unloadingIncrease flexibilityTrolley cranesContainer craneEngineering

The invention provides a container crane. The container crane comprises a crane girder (3), a main carriage (1), a main carriage lifting appliance (2), a support pillar (4) and a lifting platform (5), wherein the main carriage (1) is arranged on the crane girder (3) and can move along the crane girder (3); the main carriage lifting appliance (2) is arranged below the main carriage (1) and can move along with the main carriage (1); and the lifting platform (5) is arranged at the downstream of the main carriage (1) in the container unloading stroke in a liftable manner, and is used for lifting the to-be-unloaded container. The container crane provided by the invention can be used for well eliminating the generation of waiting time for a lorry, can be easily used for the improvement on old equipment, has greatly increased operation efficiency, and causes no increase in the cost.

Owner:SANY MARINE HEAVY IND

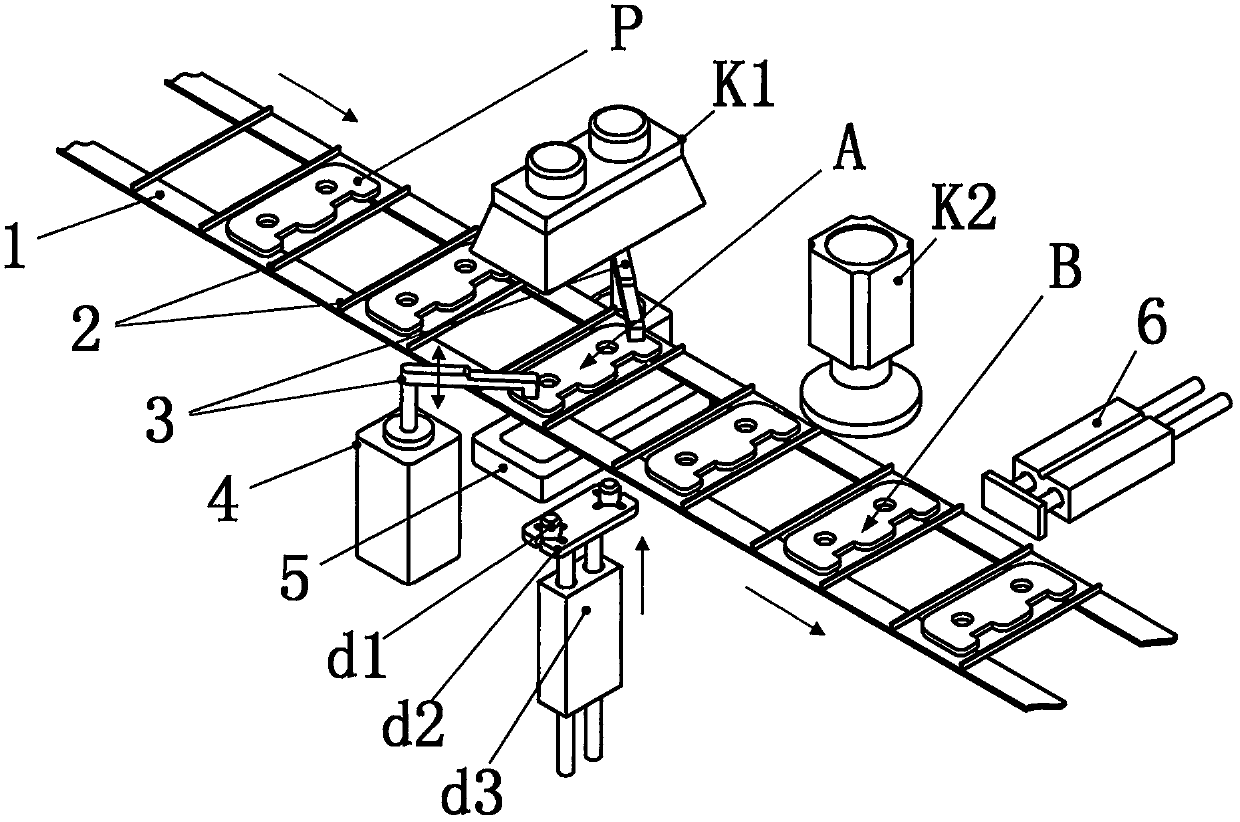

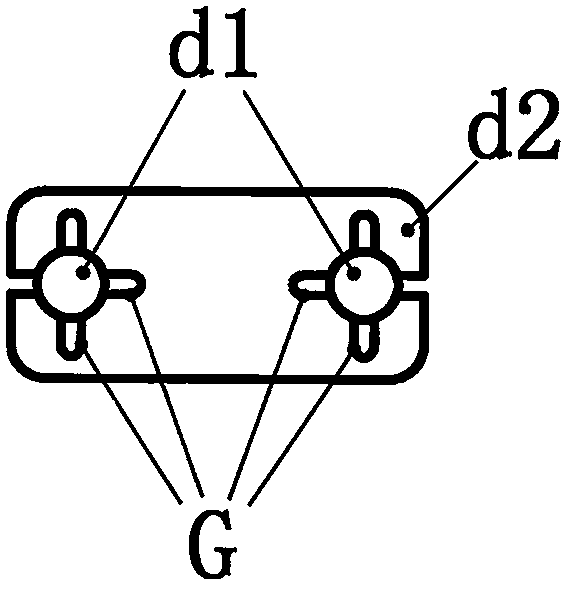

Brake block lining plate physical dimension measuring and sorting device

InactiveCN107913857AProper detection of geometric dimension qualityReasonable division of laborSortingDimension measurementEngineering

The invention relates to a brake block lining plate physical dimension measuring and sorting device, in particular to a device of online physical dimension measurement and sorting to a vehicle brake block lining plate through a high resolution camera. The device mainly aims at the problems of low product measurement automaticity, low efficiency, high labor intensity and the like lying in existingproduct manufacture. The device transfers the products to a to-be-inspected position, under the orderly cooperation of a dowel plate, a rectangle light source, a compression bar and an ejecting air cylinder, the operation of measurement and sorting of a key fit dimension and a whole physical dimension of the products can be automatically completed through a camera of fine shooting and all shooting. The device has the advantages of compact physical design, concise working process, easily realized mechanism movement, and high work efficiency and reliability.

Owner:CHINA JILIANG UNIV

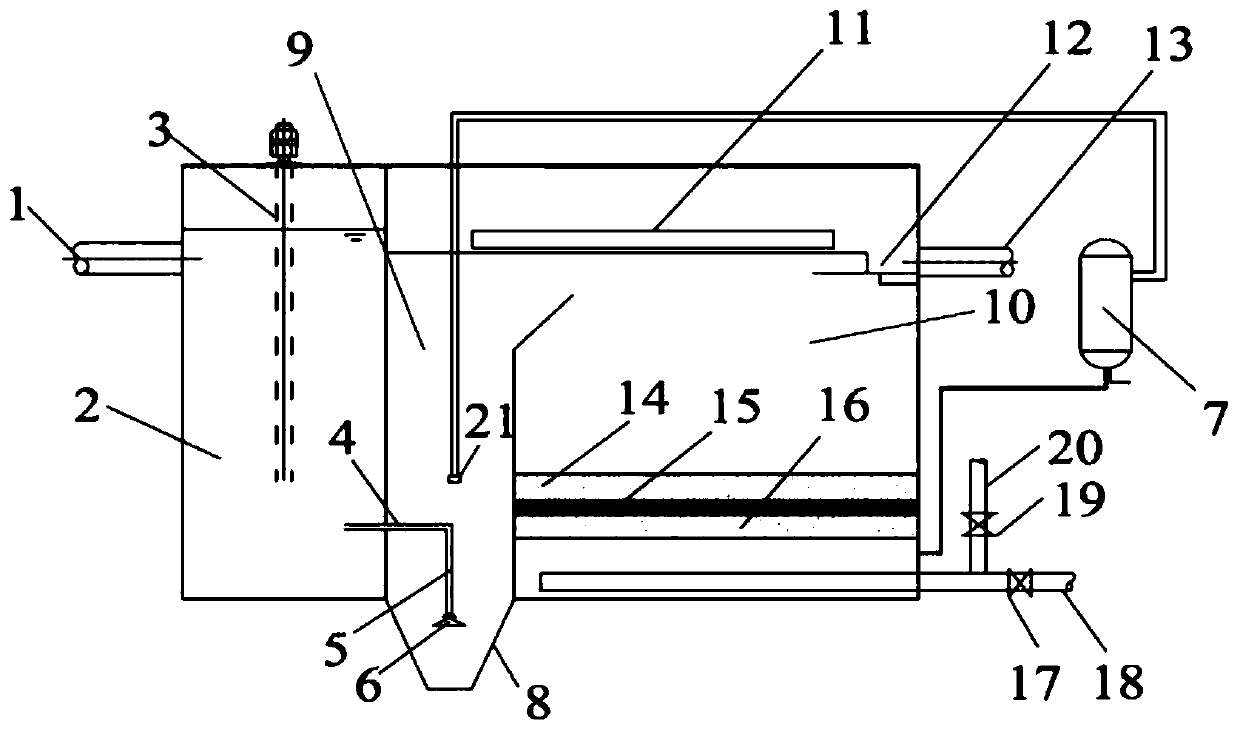

Novel air floatation tank

InactiveCN111018031AEasy to separateImprove removal efficiencyLoose filtering material filtersGravity filtersSlagSewage

The invention discloses a novel air floatation tank. The novel air floatation tank comprises a reaction zone, an air floatation separation zone and a pressure dissolved air floatation device, whereinthe reaction zone is externally connected with a sewage inlet pipe, an air floatation contact zone is arranged between the reaction zone and the air floatation separation zone, and a water passing pipe communicated with the reaction zone and the air floatation contact zone is arranged between the reaction zone and the air floatation contact zone; a vertically arranged central pipe is arranged in the air floatation contact area, and the top end of the central pipe is connected with the water outlet end of the water passing pipe; a slag scraping plate is arranged above the air floatation separation zone and the air floatation contact zone, a filter layer is arranged at the inner side of the air floatation separation zone, and the filter layer is horizontally arranged to divide the air floatation separation zone into a to-be-purified zone located above the filter layer and a clear water zone located below the filter layer; and the pressure dissolved air flotation device comprises a pressure dissolved air tank connected with the clear water zone through a pipeline, and a dissolved air water releaser installed in the air flotation contact zone and connected with the pressure dissolved air tank through a pipeline. The novel air floatation tank can effectively improve the pollutant removal efficiency and reduce the resource waste and the production cost.

Owner:ANHUI RESOURCE SAVING & ENVIRONMENTAL TECH CO LTD

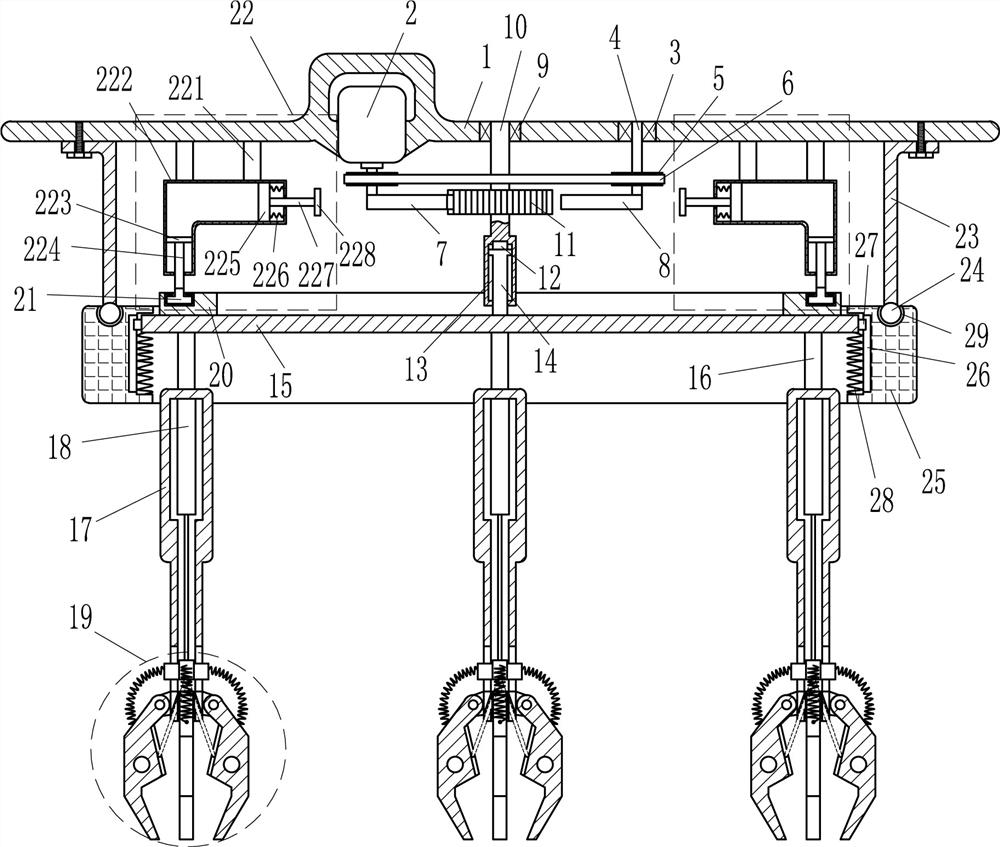

Small cargo handling device

Owner:湖南启航创客人力资源有限公司

A welding method for air purifier honeycomb mesh

ActiveCN104907658BImprove efficiencyReasonable division of laborWelding/cutting auxillary devicesAuxillary welding devicesWire gauzeManufacturing cost reduction

The invention relates to a welding method for an air purifier honeycomb mesh. The welding method comprises the following steps: I, cleaning zinc coated sheets: removing impurities from the surfaces of the zinc coated sheets which are continuously bent positively and negatively in a trapezoidal way; II, performing screen printing of soldering paste: performing screen printing of soldering paste on the joint faces of the zinc coated sheets which are continuously bent positively and negatively in a trapezoidal way through a silk screen, wherein screen printing is performed at three positions on each joint face; III, assembling the honeycomb mesh: putting the zinc coated sheets which are screen-printed with the soldering paste into a honeycomb mesh welding fixture one by one and clamping, thereby constructing the air purifier honeycomb mesh with a plurality of hexagonal holes; IV, heating and welding: putting the air purifier honeycomb mesh and the honeycomb mesh welding fixture into a drying oven for heating till the soldering paste is molten, welding, discharging and performing air cooling to the room temperature; V, loosening the honeycomb mesh welding fixture, and taking the air purifier honeycomb mesh out to obtain a finished product. The production efficiency can be increased greatly, a clad layer close to a welding spot is protected from being damaged, the product quality is enhanced, and the manufacturing cost is lowered.

Owner:SOUTHWEST COMP

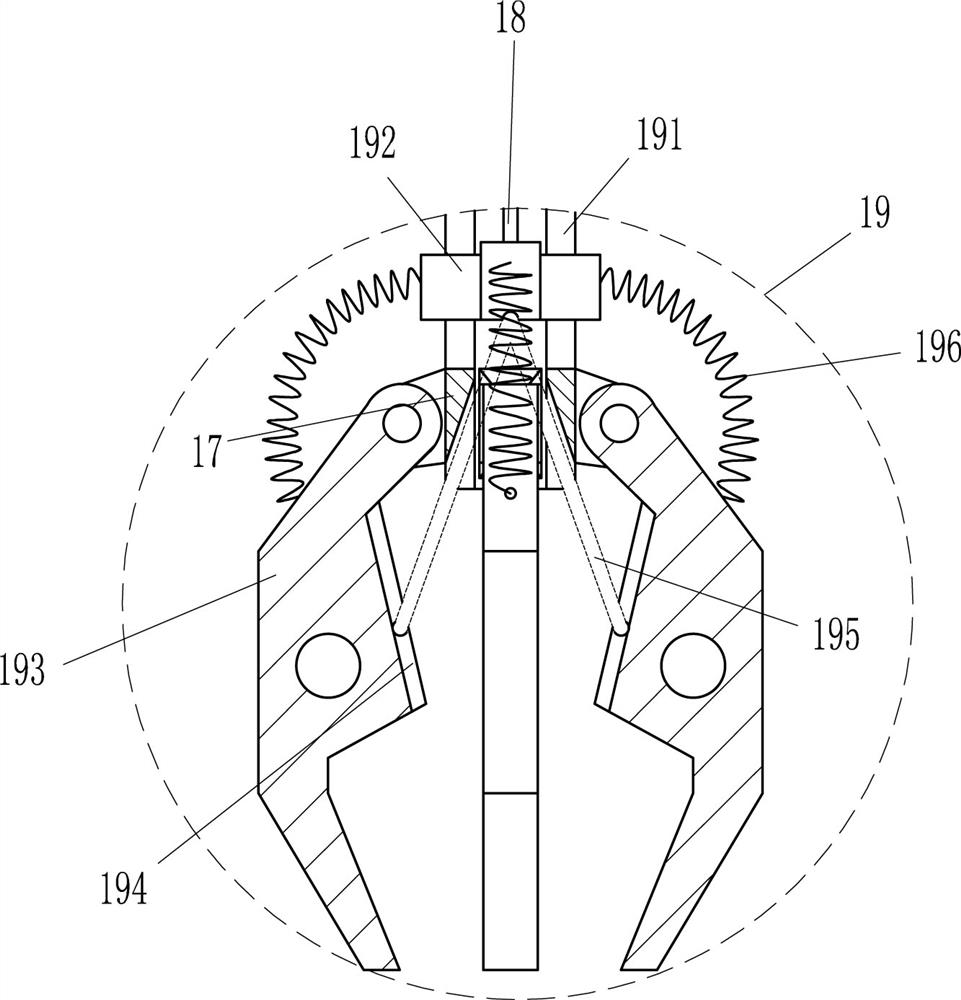

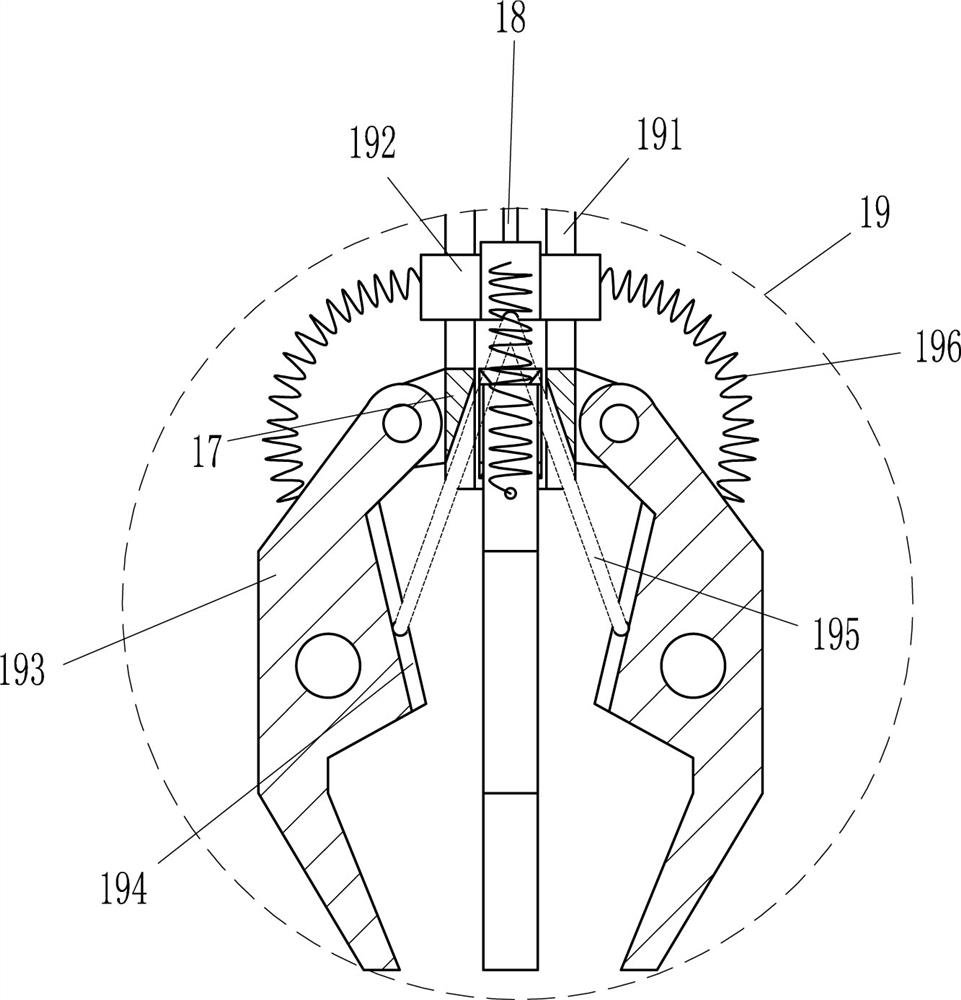

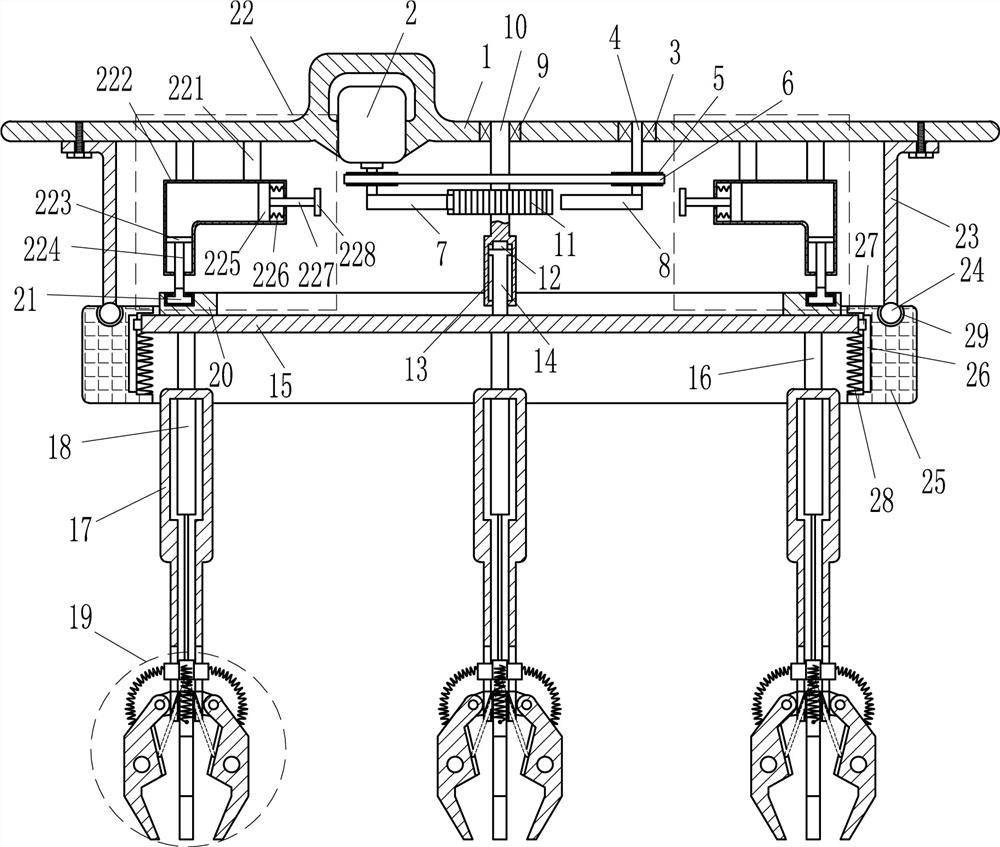

A small cargo handling device

The invention relates to a handling device, in particular to a small cargo handling device. Technical problem: Provide a small cargo handling device that can automatically transport small cargo and save manpower. The technical solution is as follows: a small cargo handling device, including a top plate, a motor, a first bearing seat, a first rotating shaft, a pulley, a flat belt, etc.; The present invention is equipped with a plurality of clamping devices, which can work continuously, speed up the speed of small cargo handling, and save manpower. When the tightening device rotates and the sector gear turns away from the full gear, the sector gear and the sector block contact the fixed block, pushing the circular plate and its upper device to move downward, so that when the circular plate and its upper device are driven to rotate, the circular plate The devices above and above will not move up and down, and the two will have a reasonable division of labor and will not conflict.

Owner:湖南启航创客人力资源有限公司

Cleaning equipment for plastic recycling

ActiveCN110405983BFully cleanedComprehensive cleaningPlastic recyclingEnvironmental engineeringMechanical engineering

The invention relates to a cleaning device, in particular to a cleaning device for recycling plastics. The technical problem to be solved by the present invention is to provide a cleaning device for plastic recycling that can clean irregular plastics without endangering human health. A cleaning device for plastic recycling, including a mounting frame, a cleaning frame, a cleaning device, a floating blocking device, a liquid inlet device, etc.; a cleaning frame is installed in the middle of the mounting frame, and a cleaning device for cleaning plastic by rotating is installed in the cleaning frame. device, the cleaning frame is provided with a floating barrier device that prevents liquid from entering through buoyancy. In the present invention, through components such as the floating plate and the first baffle plate, when the water with the disinfectant solution is put into the cleaning frame, the water with the disinfectant solution will not be discharged, and when the cleaned water is discharged, there will be no There will be water with disinfectant entering the cleaning frame, the division of labor is reasonable, and the work is more convenient.

Owner:南通微淼新材料科技有限公司

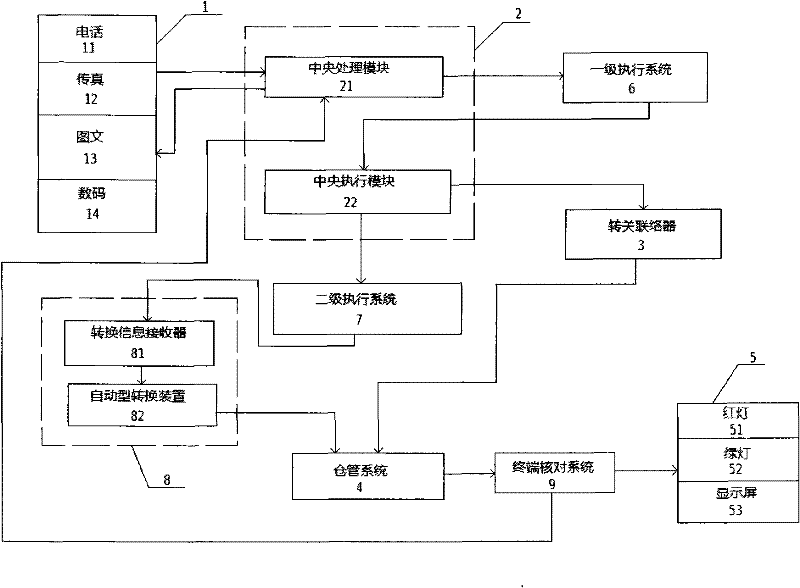

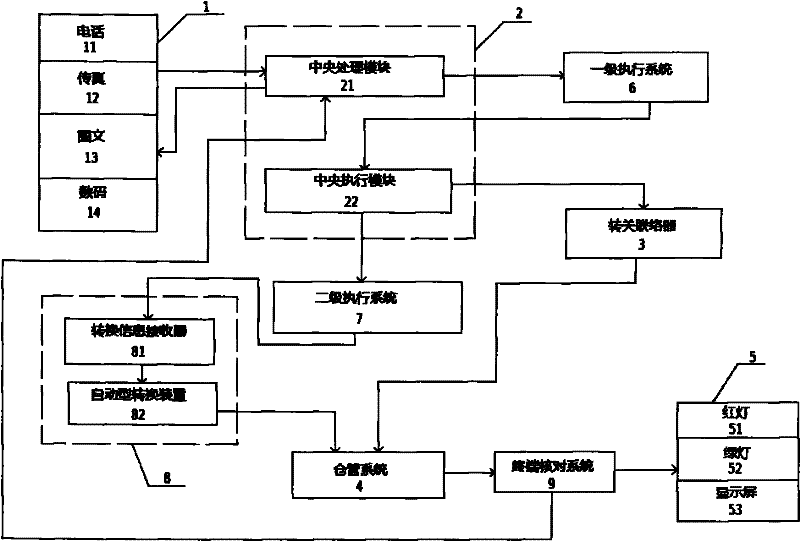

Automatic control system for export customs transfer

ActiveCN101833326BReasonable division of laborImprove computing efficiencyTotal factory controlProgramme total factory controlAutomatic controlAutomatic train control

The invention relates to an automatic control system for an export customs transfer, sequentially comprising a business contact table, a central processing table, a customs transfer contactor, a warehouse management system and a customs barrier receiver, wherein the input end of the central processing table is connected with the business contact table, and the output end of the same is connected with the customs transfer contactor; the other end of the customs transfer contactor is connected with the warehouse management system, and the other end of the warehouse management system is connected with the customs barrier receiver; the central processing table internally comprises a central processing module and a central execution module, wherein the input end of the central processing module is connected with the business contact table, and the output end of the same is connected with a first-level execution system; the other end of the first-level execution system is connected with theinput end of the central execution module, and the output end of the central execution module is connected with the customs transfer contactor; and a second-level execution system and a transfer table are connected between the central execution module and the warehouse management system. The invention not only has higher export customs transfer efficiency and accelerates the export customs transfer, but also has lower error rate and saves the customs transfer cost.

Owner:苏州工业园区报关有限公司

A rivet nut electric gun

The invention relates to an electric gun for riveting nuts, which is used in the technical field of machinery, including an outer cover, a trigger, a circuit board, a power motor assembly, a riveting system, a screw drive system, a clutch control system and a planetary gear reduction system; A circuit board, a trigger, a travel fixing board and a travel adjustment board are provided, and the circuit board is connected with the motor and the travel control board through a control line; sensors are arranged at both ends of the travel control board, and the travel fixing board and the travel adjustment board are assembled through a travel adjustment nut Control; the roller positioning block is provided with a magnet; the sensor is located under the magnet; the center line of the power motor assembly, the planetary gear reduction system, the screw drive system and the riveting system are on the same axis as the riveting direction. The electric gun has strong power and can be used indoors and outdoors. It is ergonomic when used in hand. It has the largest tool space and can be riveted on rivet nuts of different specifications. The clutch control system is more reliable, the riveting system is more stable, and the applicability powerful.

Owner:洪劲松

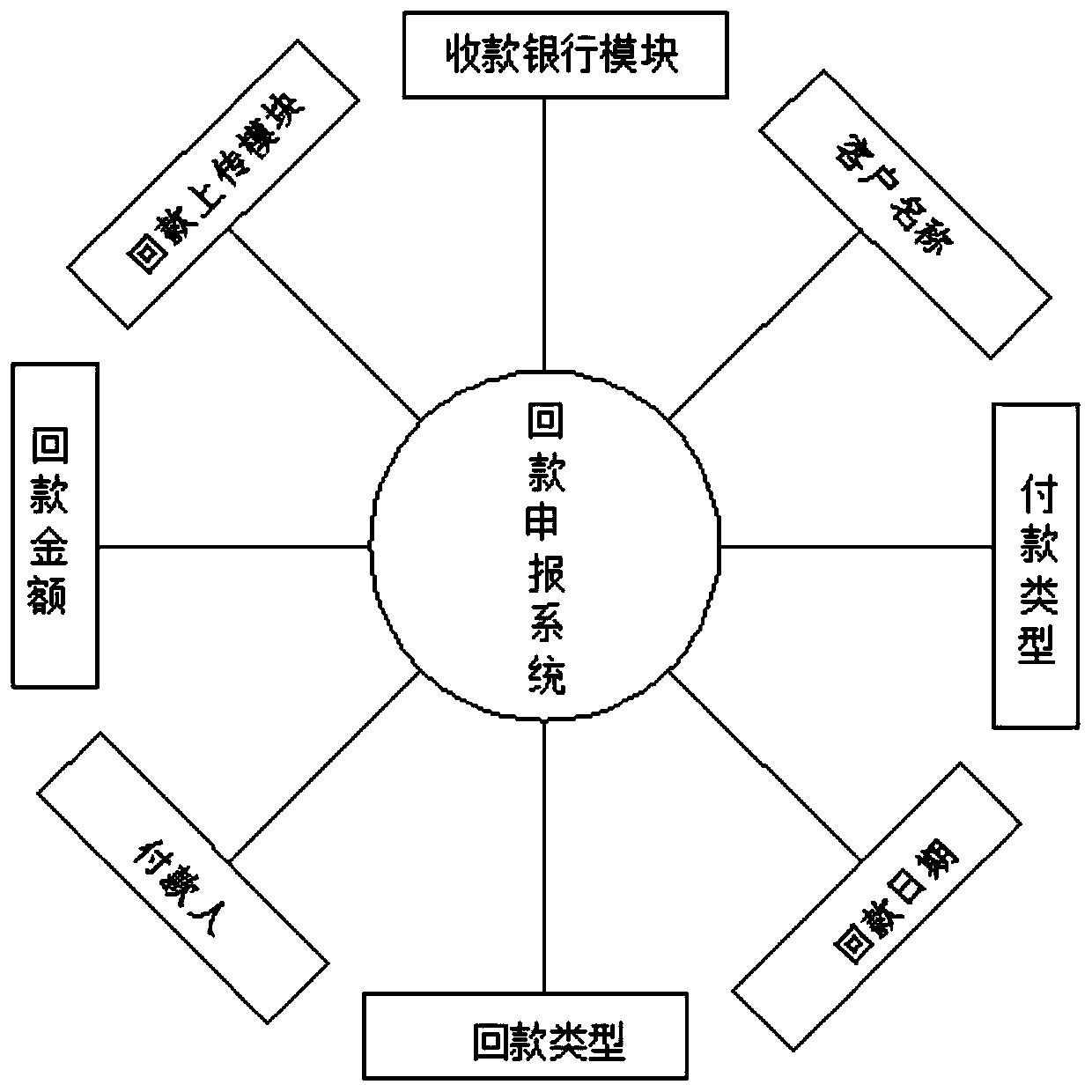

Client money return processing method

PendingCN110189217AImprove efficiencyImprove accuracyFinancePayment architectureBusiness PersonnelComputer science

The invention discloses a client money return processing method, which comprises the following steps that: step 1, a business person reports client money return through a money return application system in a mobile phone APP, and fills in necessary money return information; 2, generating bank collection information through a collection bank module in the return money declaration system; and step 3, after receiving the bank receipt information, the financial staff finds out a corresponding refund declaration from the undetermined refund records through the mobile phone APP or the PC, and confirms the refund declaration. The method has the beneficial effects that the repayment business part processed by the financial department is transferred to the business personnel because the business personnel directly face the client, and the repayment of the client is very clear; therefore, in this way, the returned money information is filled and distributed to the business personnel who most knows the situation, the financial personnel only need to confirm the accuracy of the amount of money, labor division is more reasonable, and the overall efficiency of a company is improved.

Owner:合肥博耀信息技术有限公司

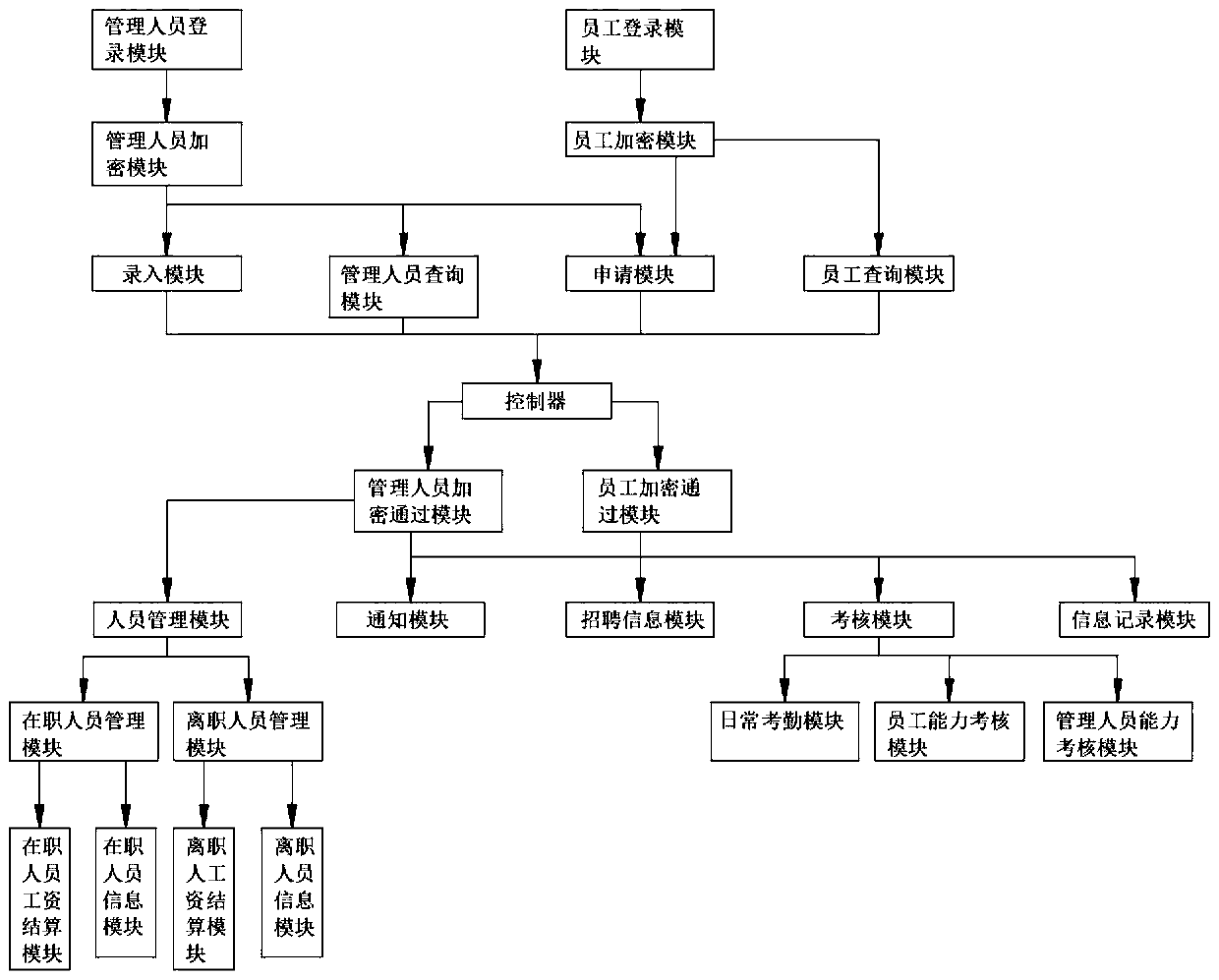

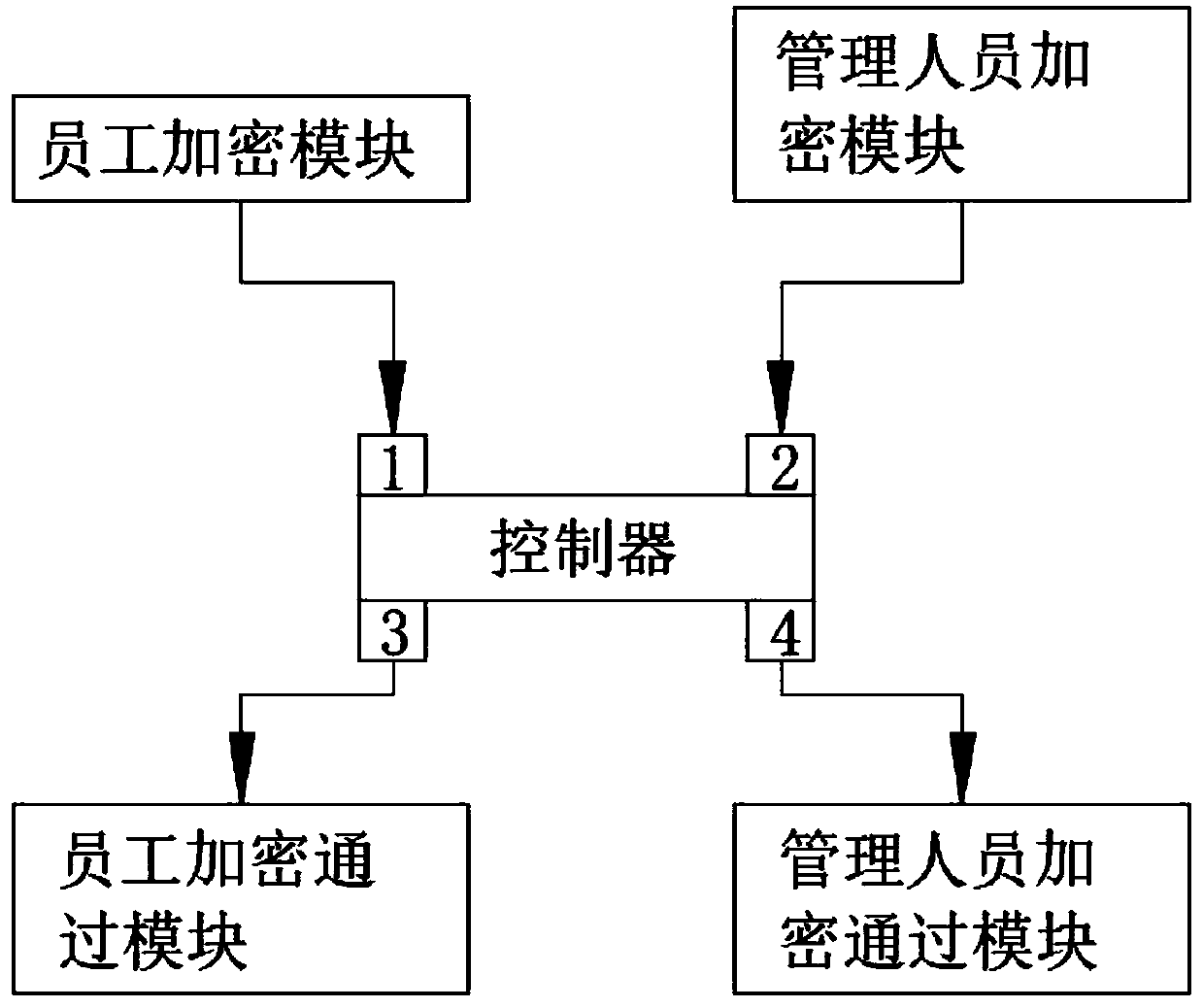

Human resource management system and mode

PendingCN111598552ARealize managementAchieve recordDigital data protectionDigital data authenticationConfidentialityHuman resource management

The invention discloses a human resource management system and mode and relates to the field of human resource management. The system comprises a personnel management module, a notification module, arecruitment information module, an evaluation module and an information recording module. The system can realize personnel management, notification issuing, recruitment information management, evaluation information management and recording of other object information, is high in practicability, relates to more management fields, and plays a role in managing overall human resources. According to the invention, the input end of the personnel management module is electrically connected with the output end of the management personnel encryption passing module; the input end of the administrator encryption passing module is electrically connected with the output end of the controller, the input module, the administrator query module, the application module and the employee query module can beused at the same time through the administrator encryption passing module, labor division is reasonable, information leakage is avoided, enterprise information is only opened to administrators, and confidentiality is good.

Owner:JIANGSU INST OF ECONOMIC & TRADE TECH

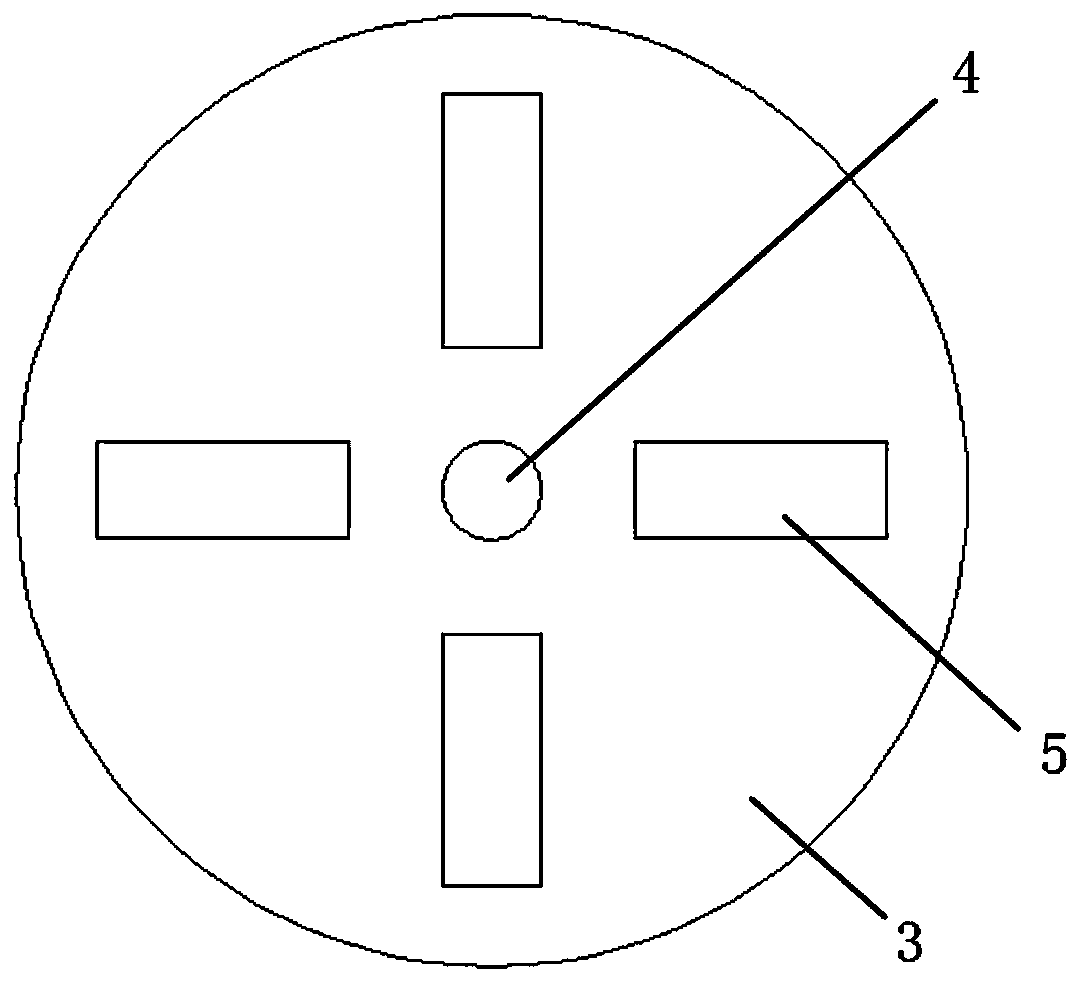

Hole opening equipment for building materials

InactiveCN110052639BReasonable division of laborAvoid eccentricityDrilling/boring measurement devicesMaintainance and safety accessoriesArchitectural engineeringElectric machinery

The invention discloses tapping equipment for building materials. The tapping equipment comprises a top plate, a pipe body and a bottom plate, the bottom plate is provided with a central through holeand a plurality of strip-shaped through holes, a driving motor with a tapping drill bit is arranged in an inner cavity of the pipe body, a guide column penetrates through a middle supporting plate ofthe driving motor, and the guide column is fixed on the inner wall of the pipe body through a positioning block, the outer side of the guide column is sleeved with a first spring, the lower end of thepositioning block is connected with a first propping block through a second spring, the first propping block is in sliding connection with a second propping block, a driven pressure rod is arranged above the first propping block, the lower end of the first propping block extends to form an anti-deflection block, and a main pressure rod with a handle penetrates through the top plate. The first propping block and the second propping block are reasonable in division of work, the first propping block prevents eccentricity of a drill rod by the anti-deviation block on the first propping block, andthe second propping block makes contact with plates by a pressing foot, so that the anti-skid effect is good; the exhaust heat radiation system is reasonable in design, an extra motor is needed, a main shaft of the driving motor is used for driving a fan blade assembly to rotate, and good heat radiation is realized.

Owner:安徽职业技术学院

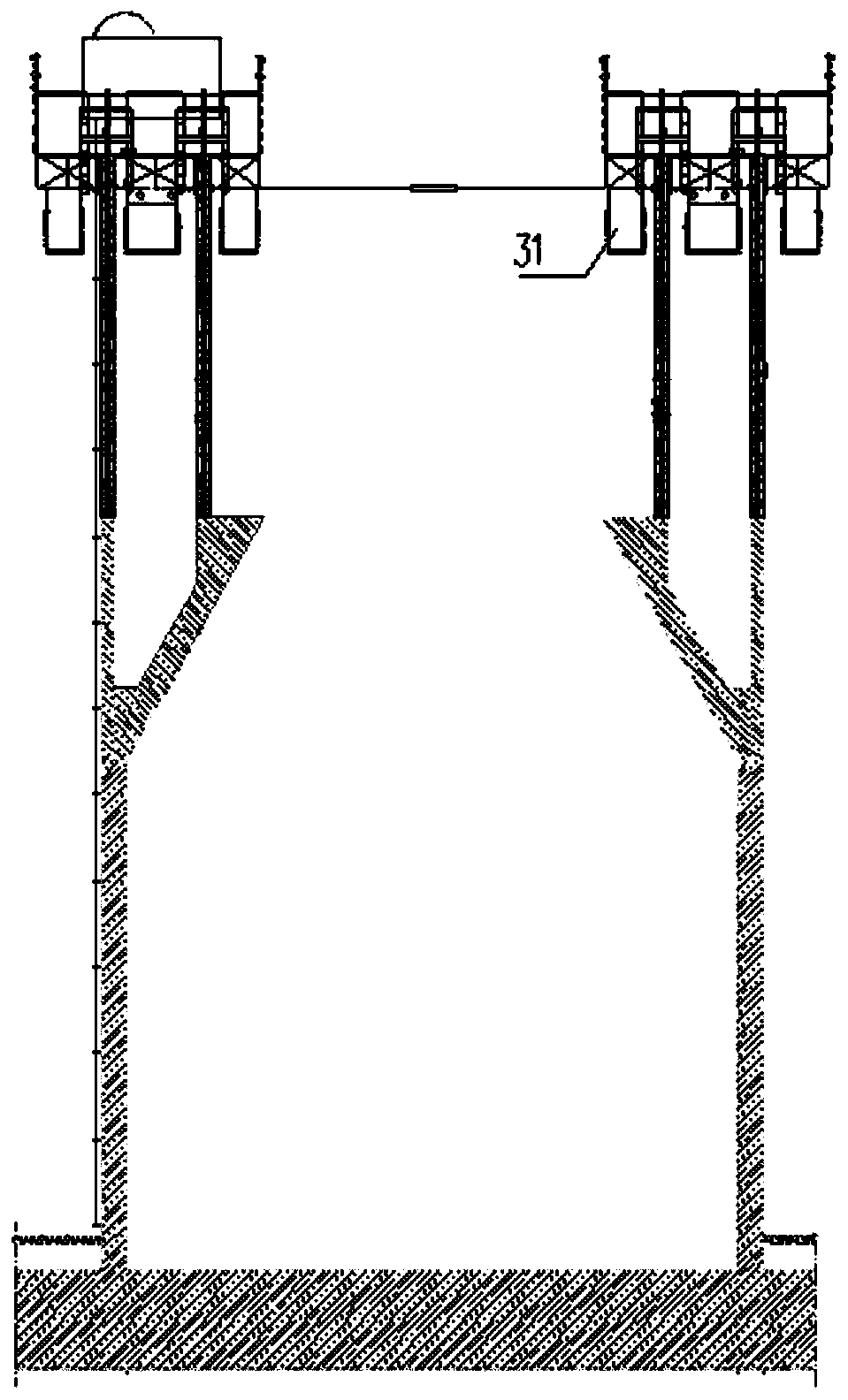

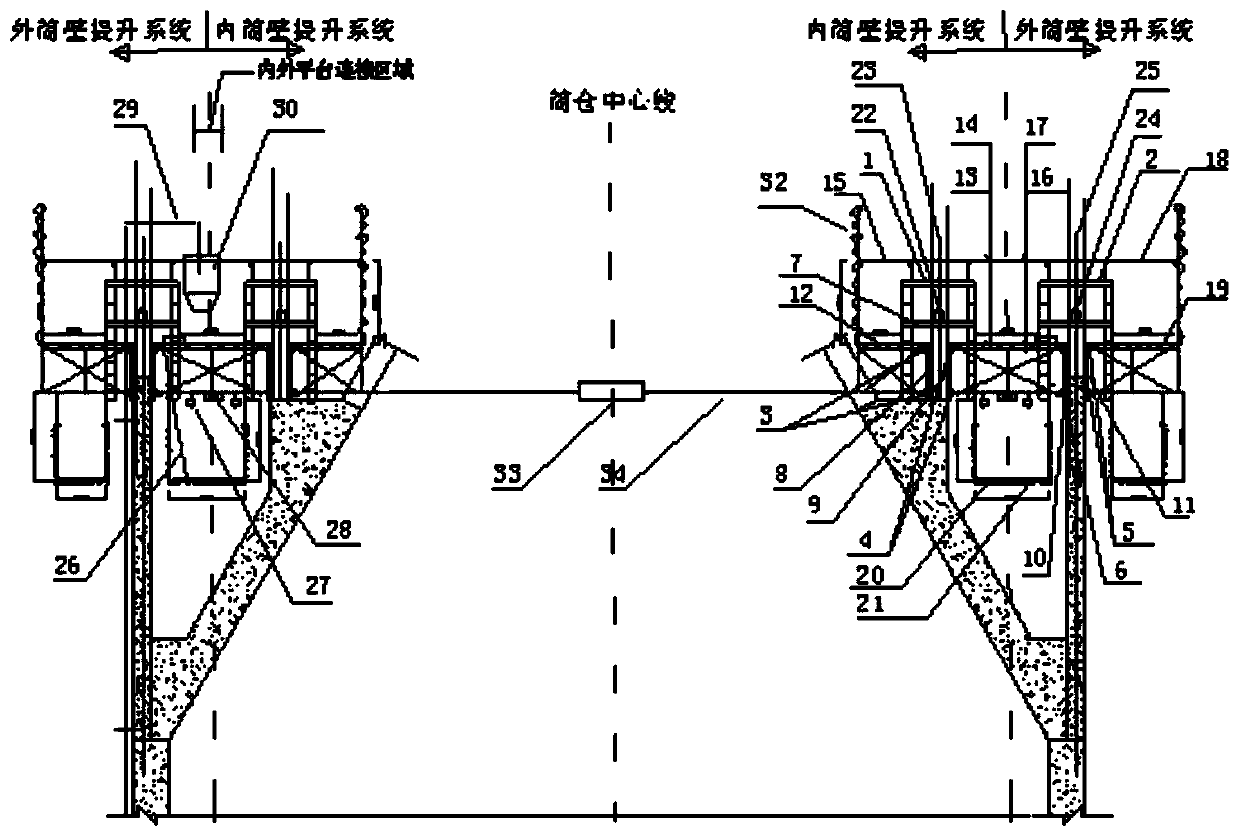

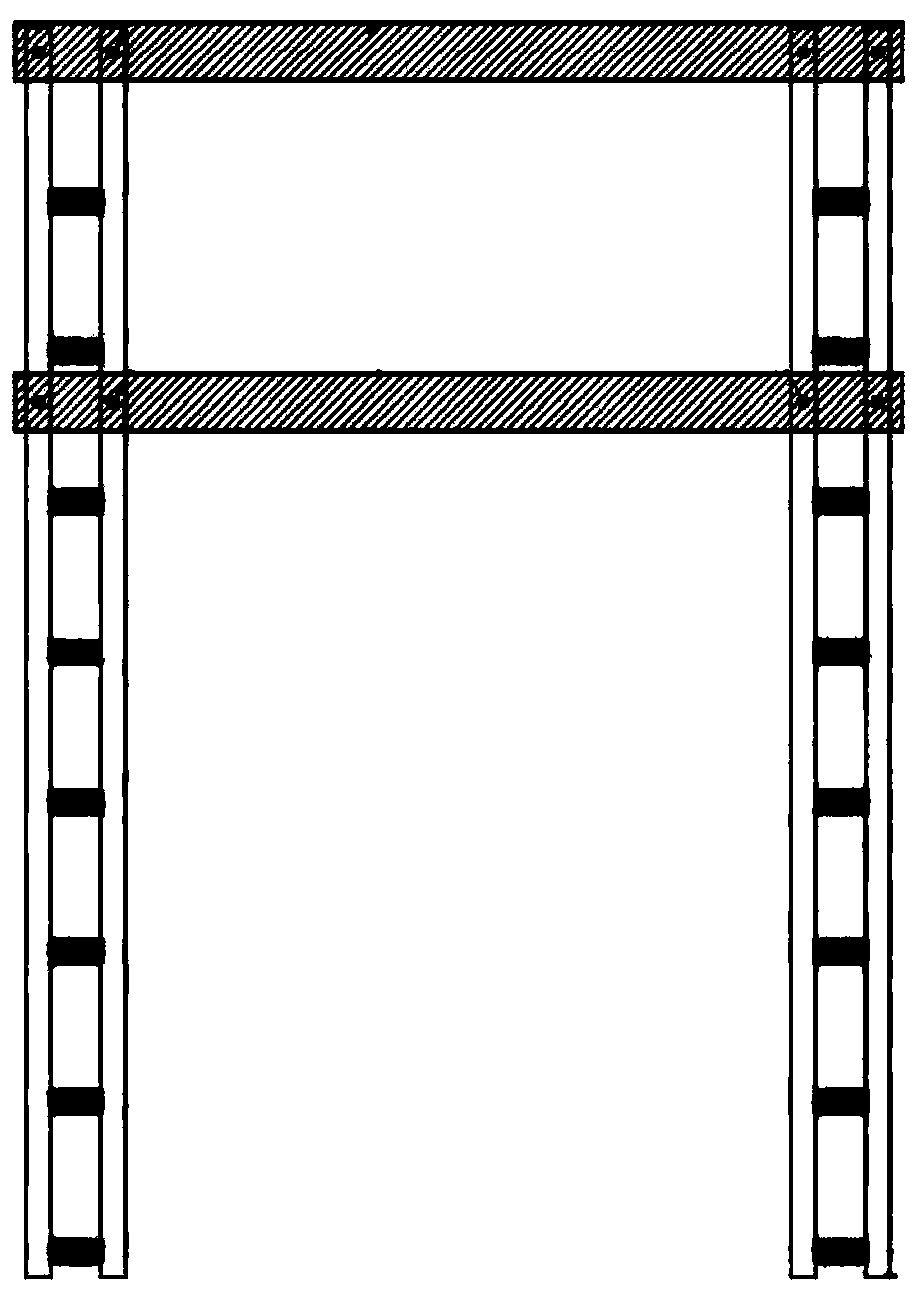

Double-cylinder-wall concrete silo slip form construction operation platform and construction method

PendingCN111424969ARelieve pressureInterspersed orderlyForms/shuttering/falseworksBuilding support scaffoldsArchitectural engineeringRebar

The invention discloses a double-cylinder-wall concrete silo slip form construction operation platform and a construction method. The double-cylinder-wall concrete silo slip form construction operation platform comprises an outer cylinder wall lifting system and an inner cylinder wall lifting system which are synchronously lifted, wherein the outer cylinder wall lifting system and the inner cylinder wall lifting system each comprise an inner side platform and an outer side platform, each of the inner side platforms and the outer side platforms comprises an upper layer, a middle layer and a lower layer, and the three layers of platform bodies on the outer side of the inner cylinder wall and the three layers of platform bodies of the inner side of the outer cylinder wall are correspondinglyconnected into a whole; and the upper-layer platform bodies are used for temporarily stacking slip form construction materials, the middle-layer platform bodies are used for steel bar binding, concrete transportation and pouring and tamping space, and the lower-layer platform bodies are used as a platform for receiving light, maintaining and checking after concrete is out of the forms. The three layers of platform bodies are reasonable in work division, and the requirement for slip form simultaneous lifting of a double-cylinder-wall silo is effectively met. By means of the double-cylinder-wallconcrete silo slip form construction operation platform and the construction method, the inner cylinder wall and the outer cylinder wall are connected into the whole on the basis of an original single-cylinder-wall slip form, so that the overall stability of a slip form system is improved, the slip form is lifted through the double cylinder walls at the same time, and the construction period is greatly shortened.

Owner:MCC5 GROUP CORP SHANGHAI

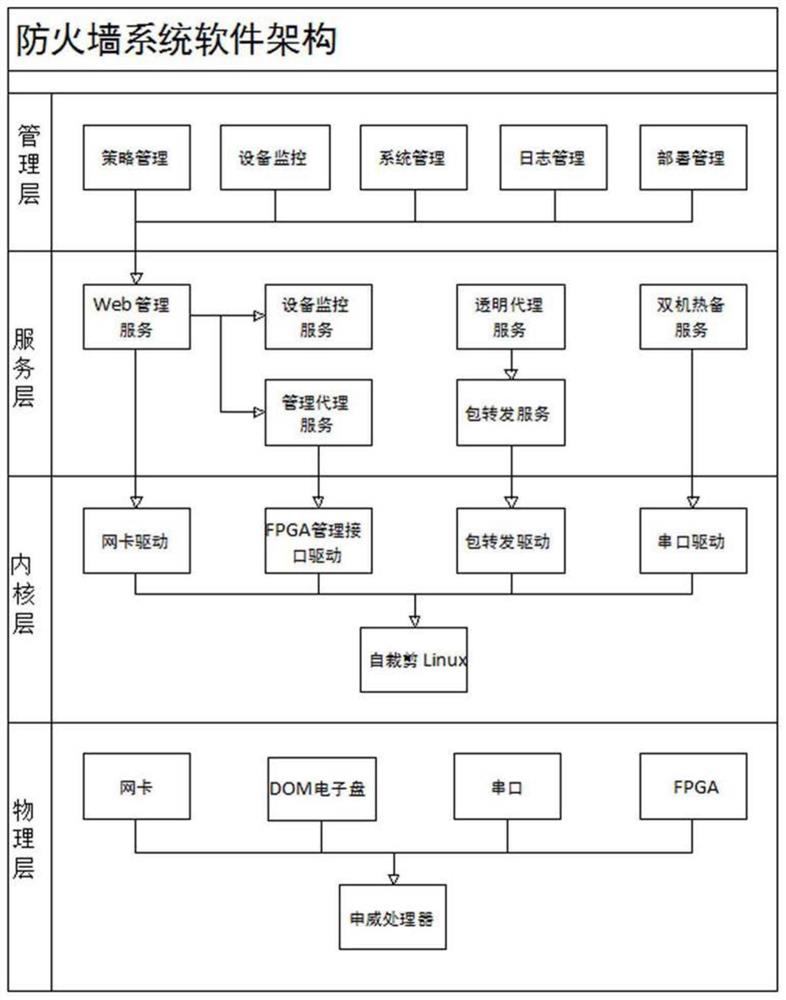

Firewall system architecture

InactiveCN112995093AMeet the needs of safe and reliable communicationIntegrity guaranteedTransmissionOperational systemWeb browser

The invention discloses a firewall system architecture. The system architecture is divided into a management layer, a service layer, a kernel layer and a physical layer from top to bottom. The management layer adopts a B / S framework and provides a GUI management mode based on a Web browser; the service layer comprises a daemon process, provides support for the functions of the management layer and completes the functions of a firewall; the kernel layer comprises an operating system and a device driver of the firewall; the physical layer is a hardware environment of the firewall and comprises a processor, a network card, a memory, a serial port and an FPGA chip. Compared with the prior art, the firewall system architecture has the advantages that the flow entering and exiting the intranet can be filtered, the network security is ensured, the network abuse is reduced, the security risk of the network is reduced, the practicability is high, and the popularization is easy.

Owner:王珠

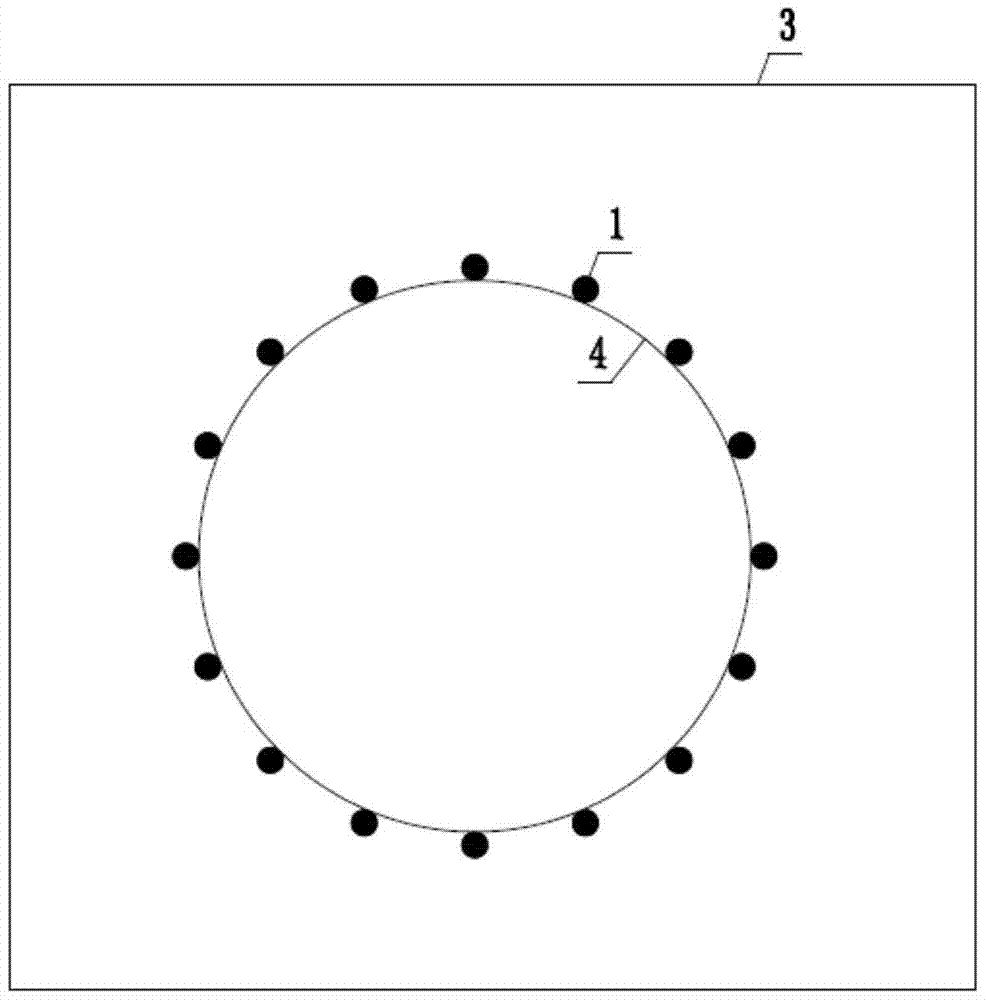

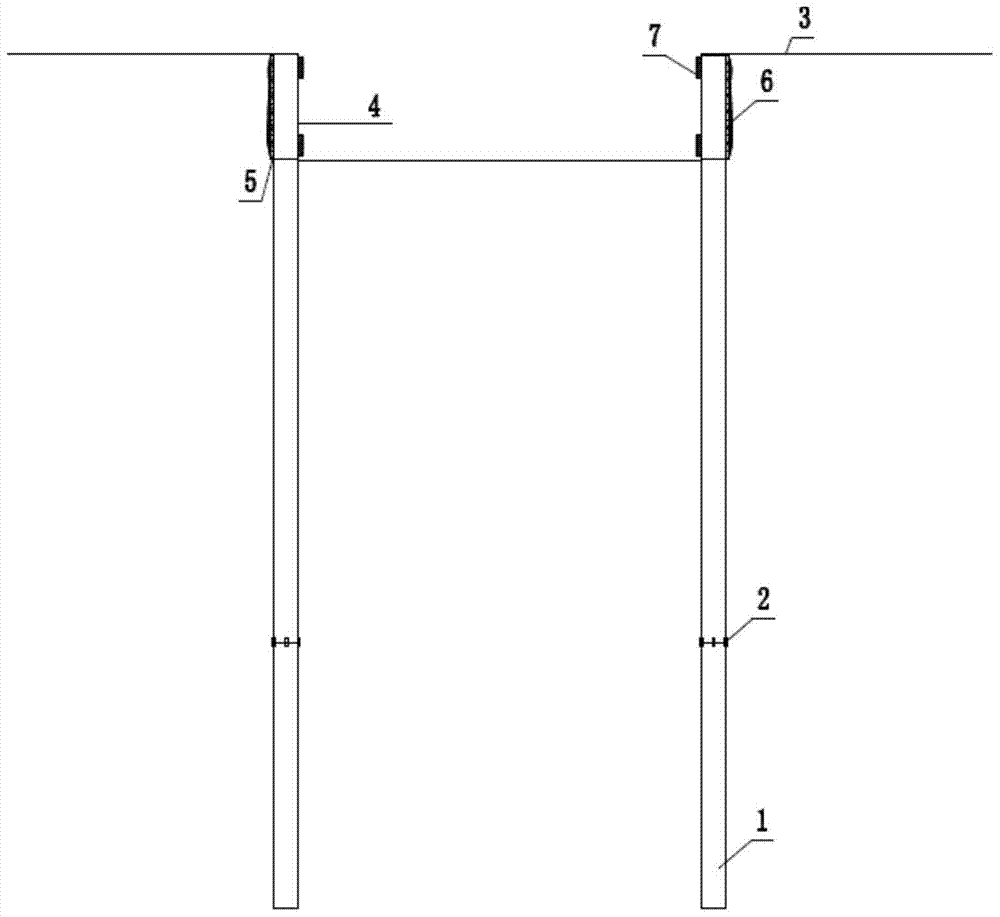

A Design and Construction Method of High Polymer Grouting Excavation Support Structure for Small Diameter Shaft

ActiveCN105672327BAdvanced technologyImprove economic indicatorsExcavationsEngineeringStructure system

The invention relates to a design construction method of a small-diameter shaft high polymer grouting excavation support structure. The method comprises the following steps: (1) micro support piles are constructed; (2) a small-diameter shaft is excavated; and the side wall high polymer grouting is constructed in a closed manner; (3) lining structures between the micro support piles are constructed; and according to an excavation depth and a calculation result, the lining structures are constructed between the micro support piles; (4) the layered and segmented excavation is vertically performed in sequence; the steps (2) and (3) are repeated to construct to reach a designed depth; and the construction of the small-diameter shaft high polymer grouting excavation support structure is finished; and (5) after the support structure finishes the use function, the recovery work of the support structure can be performed along with beginning of the backfill work. The constructed support structure system has such advantages as safety, reliability, fast construction, advanced technology, recycling capacity and excellent economic index.

Owner:SAFEKEY ENG TECHZHENGZHOU

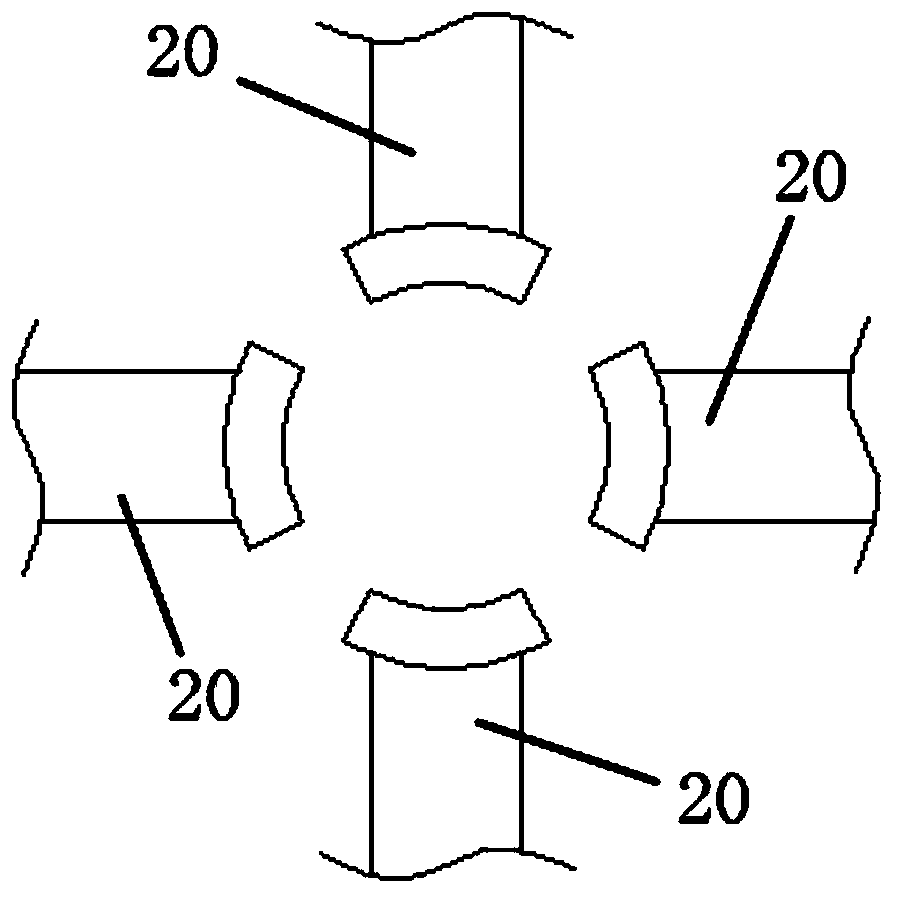

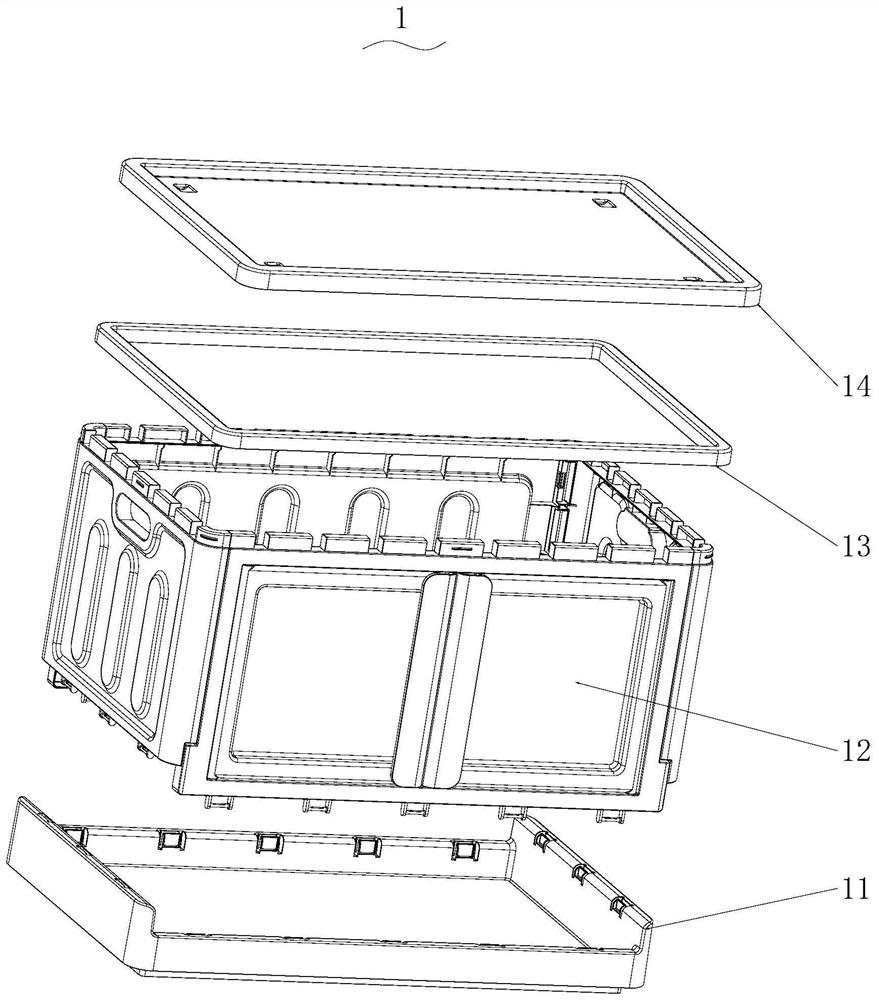

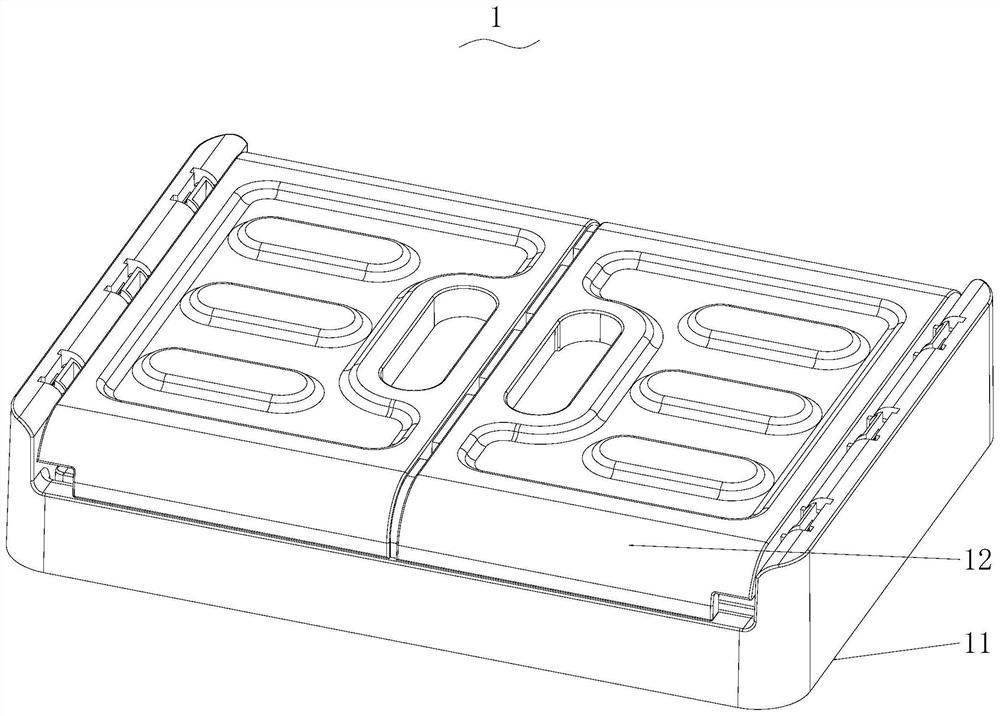

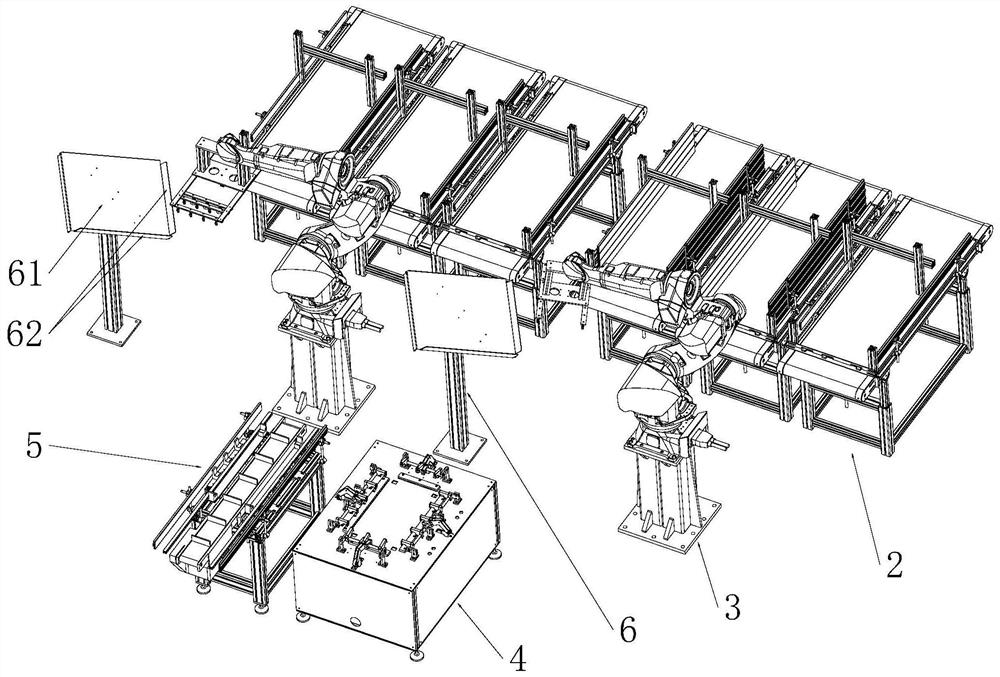

Assembling equipment for folding storage box

PendingCN114346648AReasonable division of laborMechanizationMetal working apparatusRobot handEngineering

The invention discloses assembly equipment for a folding storage box. The assembly equipment comprises a component conveyor, a manipulator, a storage box main body assembly mechanism and a final assembly conveyor. And a plurality of component conveyors are arranged. The storage box main body assembling mechanism is used for assembling a plurality of components of the storage box together; the storage box body assembling mechanism comprises a supporting plate and a plurality of press-fitting mechanisms, the supporting plate is provided with a containing station used for containing components of a storage box, and the multiple press-fitting mechanisms are arranged on the periphery of the containing station in a surrounding mode. The press-fitting mechanism comprises a bearing seat mounted on the supporting plate, a rotating shaft pivotally connected with the bearing seat, a plurality of pressing heads fixedly connected with the rotating shaft and arranged at intervals in the axial direction of the rotating shaft, and a pressing driving mechanism in driving connection with the rotating shaft to drive the rotating shaft to rotate around the axis of the rotating shaft. The final assembly conveyor is provided with a feeding station and a discharging station which are sequentially arranged in the conveying direction of the final assembly conveyor. The full mechanization of the folding storage box production process can be realized, so that the production efficiency is improved.

Owner:GUANGDONG HAIXING PLASTIC & RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com