Online product quality detection device used on beer filling production line

A product quality and detection device technology, which is applied in the direction of measuring devices, lubrication indicating devices, engine lubrication, etc., can solve the problems of high labor intensity, high detection cost, and difficulty in summarization, etc., and achieve improved detection accuracy and stability, detection The requirements and functions are clear, and the effect of avoiding too much interference in the bottom area of the bottle is avoided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

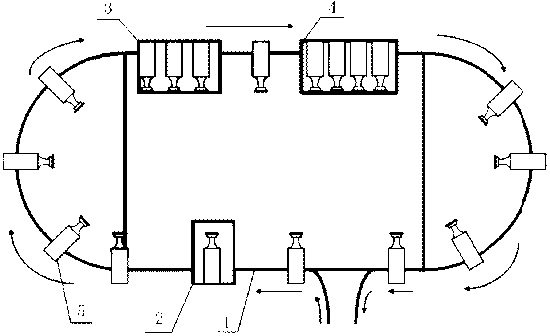

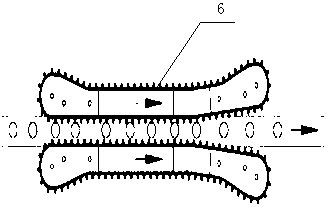

[0011] to combine figure 1 The schematic diagram of the structure of the present invention is shown, and the present invention is specifically described. The present invention includes detection station I2, detection station II3 and detection station III4, and detection station I2, detection station II3 and detection station III4 are located at the clamping beer bottle 5 and turned over on the mechanical transmission 1. To detect the filled beer, first determine the common foreign matter inside, such as floating matter (foam block, plastic block) whose density is much smaller than that of beer, and suspended matter (paper pieces, large mold spots and mosquitoes) whose density is closer to beer ), the sediment (glass, metal block, stone cement, etc.) whose density is much higher than that of beer is classified into stages, the detection station is determined, and the detection state of three stations is realized by using the flip-type mechanical transmission device. The detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com