Pedal control gem shaping machine

A control type, setting machine technology, used in manufacturing tools, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problem of retrofitting and retrofitting of pedal-type floor adjustment devices, unfavorable renewal of existing equipment, and large investment costs. problems, to achieve the effect of improving production efficiency and economic benefits, reducing industrial accidents, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

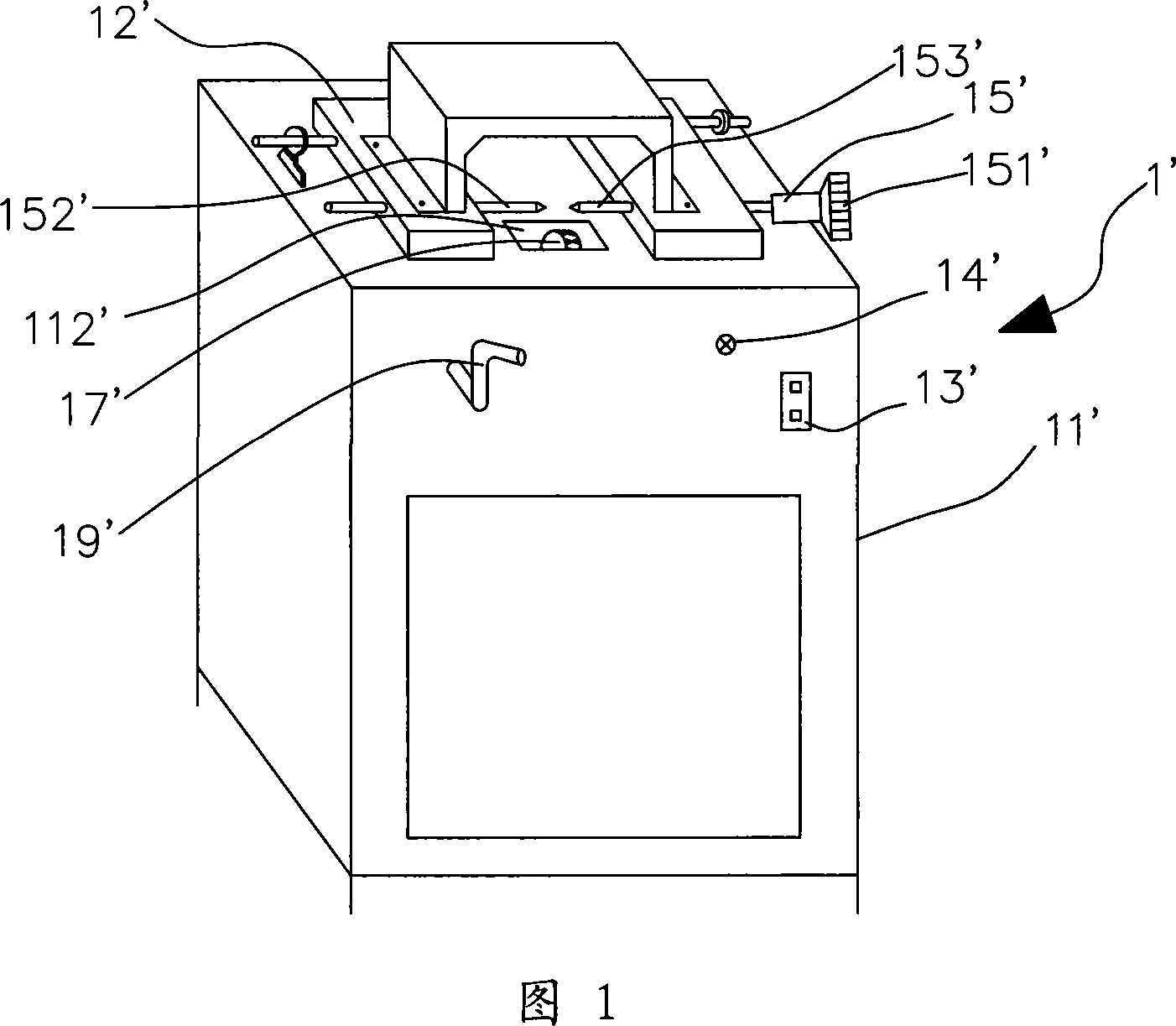

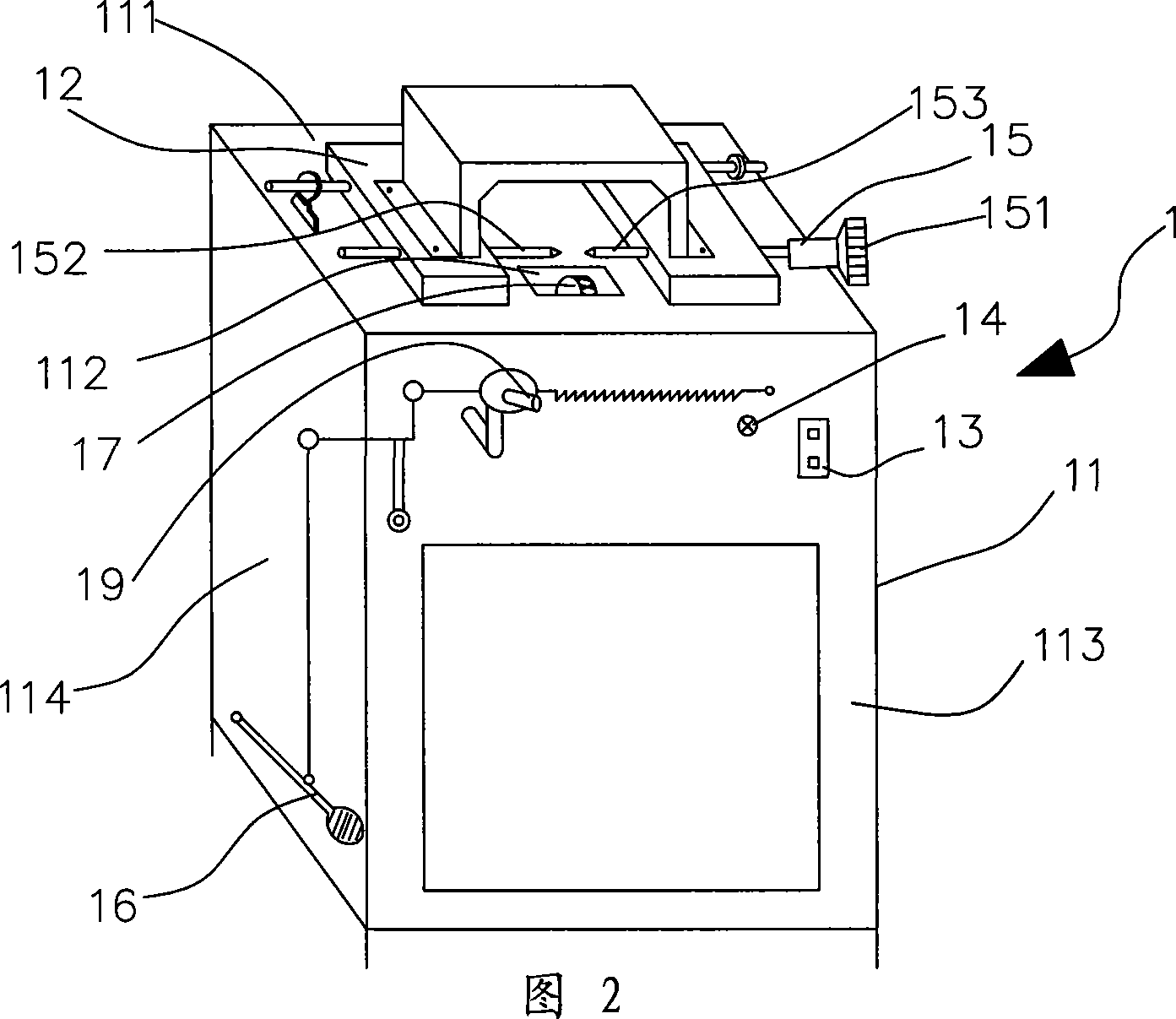

[0023] As shown in Figure 4, the pedal-controlled gem setting machine 1 of the present invention includes a base 11, a grinding wheel 17 installed inside the notch 112 on the upper surface 111 of the base 11, and a machine head installed on the upper surface 111 of the base 11. 12. The machine head lifting operation lever 19 for directly controlling the height of the machine head, the switch 13 and the indicator light 14 arranged on the front surface 113 of the base 11, the advance and retreat mechanism 15 for clamping the workpiece, and the mechanism for controlling the up and down movement of the machine head 12 Pedal toggle mechanism 16.

[0024] The advancing and retreating mechanism 15 includes a left shaft 152 of the shaping machine, a right shaft 153 of the shaping machine and an advancing and retreating handle 151, and the workpiece is clamped between the left shaft 152 of the shaping machine and the right shaft 153 of the shaping machine.

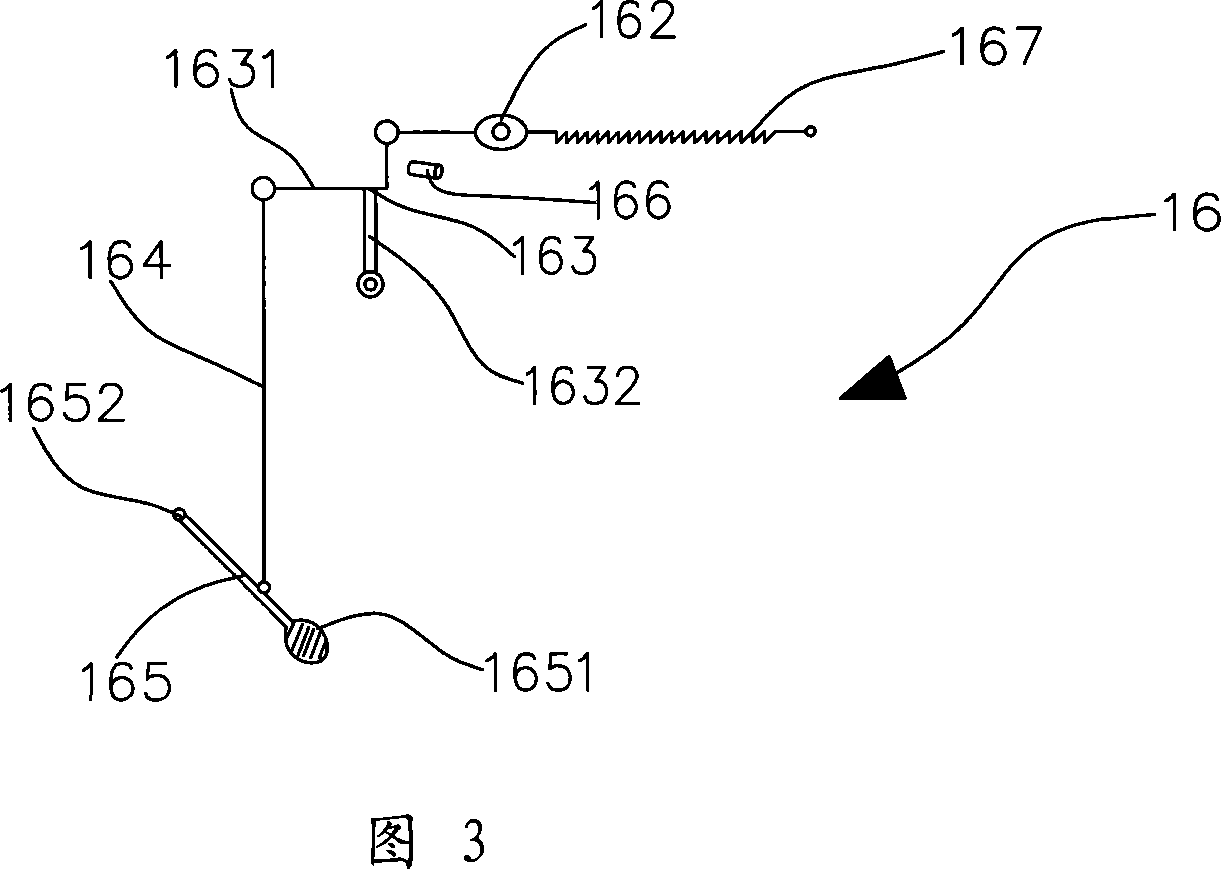

[0025] The pedal toggle mec...

Embodiment 2

[0029] As shown in Figure 4 and Figure 5, as another embodiment of the present invention, other parts are the same as in Embodiment 1, the difference is:

[0030] The pedal toggling mechanism 36 is arranged on the outside of the base 11 except the pedal 365, and all other components are arranged on the inside of the base 11. Such a pedal-controlled gem setting machine 1 has a simple and beautiful appearance.

[0031] Pedal toggling mechanism 36 comprises pedal 365, pedal sleeve 362, puller puller bar 364, location code one 3662, soft cable 3665, location code two 3667, cable lug 3669, mechanical handle 367, eccentric lifting shaft 368 and return spring 369. Wherein, a cam 3688 is fixed on the eccentric lifting shaft 368, and the return spring 369 is a scroll spring or a torsion spring fixed on the eccentric lifting shaft 368.

[0032] During use, the movement of the pedal 365 will pull the soft cable 3665, and the soft cable 3665 will make the mechanical pull handle 367 rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com