Brake block lining plate physical dimension measuring and sorting device

A technology of geometric dimensions and sorting devices, applied in sorting and other directions, to achieve the effects of high work efficiency and reliability, simple work process, and reasonable division of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

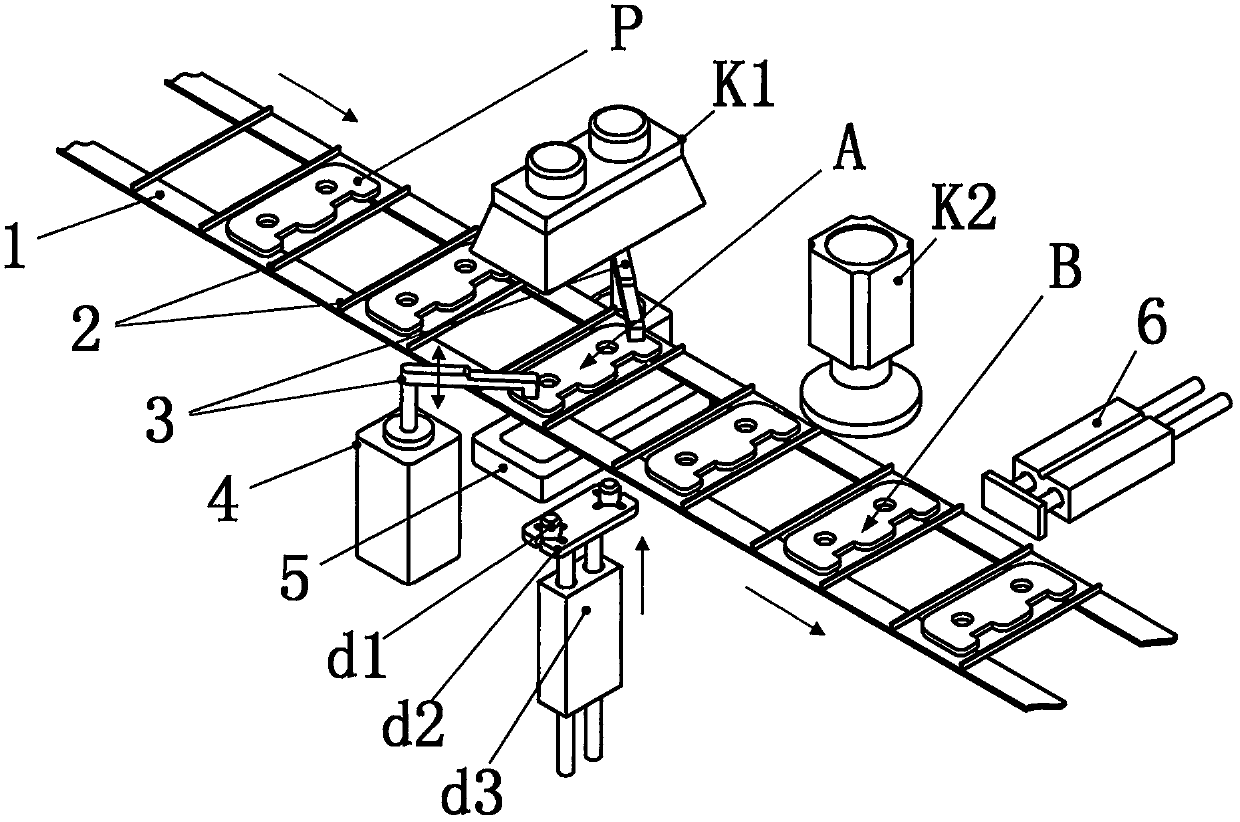

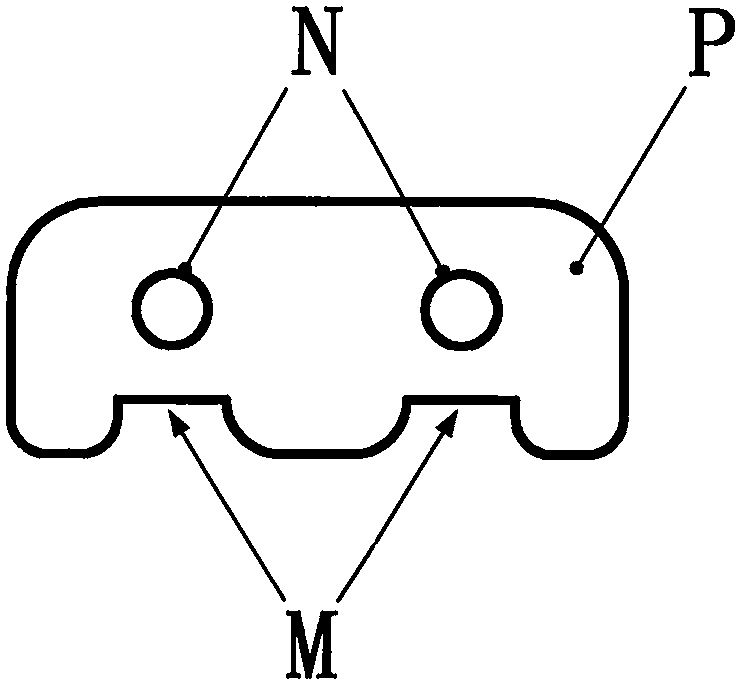

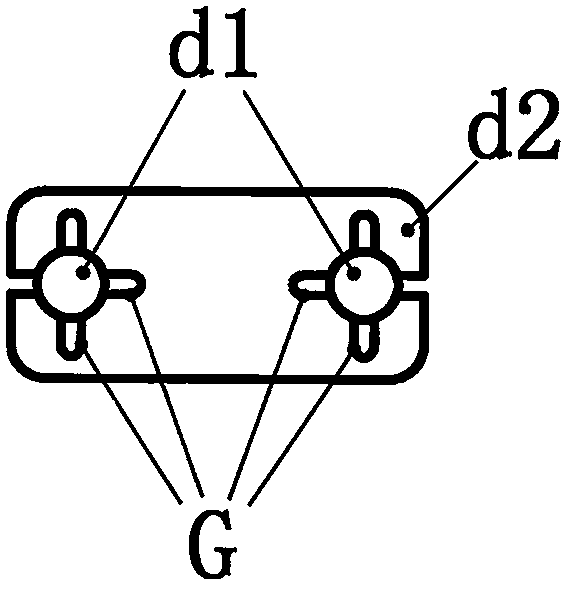

[0020] Brake pad liner P takes the commonly used specifications of a certain brand as an example, and its overall dimensions (length×width×thickness) are about: 170mm×75mm×6.5mm. In this embodiment, the overall dimensions (length×width) of the conveyor belt 1 are set to 1200mm×200mm. The external dimensions of the rectangular light source 5 (length × width × height) are set to 230mm × 135mm × 25mm, the inner rectangular dimensions (length × width) are set to 190mm × 85mm, and the external dimensions of the positioning pin plate 7 (length × width × thickness) are set to 160mm×55mm×8mm, the length and width dimensions are smaller than the inner rectangular size of the rectangular light source 5 , so that the positioning pin plate d2 can pass through the rectangular light source 5 vertically without any obstacles. In this embodiment, the transmission li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com