Hanging basket structure

A technology of trusses and main longitudinal beams, applied in the field of hanging basket structures, which can solve the problems of increased weight of hanging baskets, inconvenient construction of hanging baskets, slow construction of hanging baskets, etc., and achieve the effects of shortening the construction period, convenient construction, and reducing the number of rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

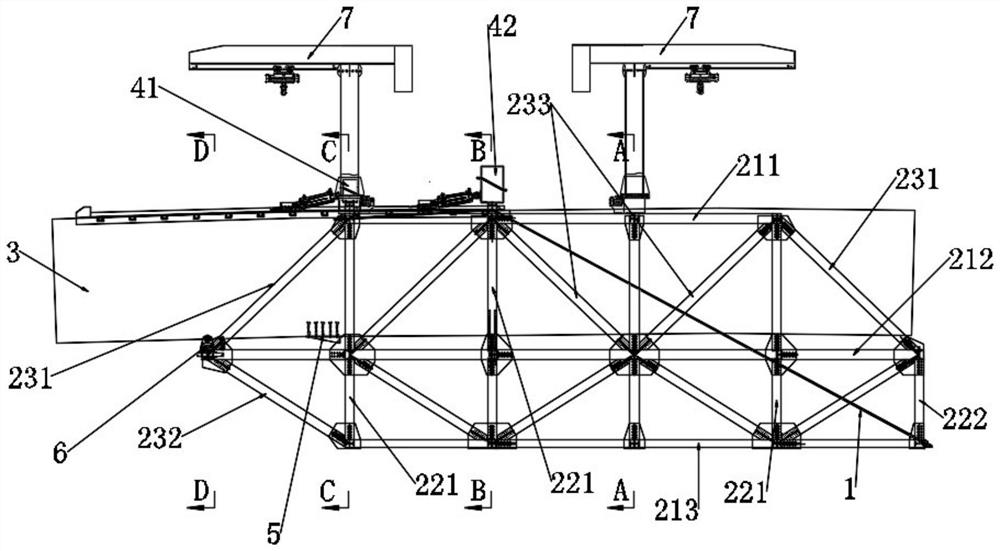

[0039] This embodiment provides a hanging basket structure, see figure 1 , including a truss load-bearing system, a walking system, a support reaction system 6 and a thrust system 5, and the travel system, a support reaction system 6 and a thrust system 5 are all installed on the truss load-bearing system, and at least two pre-loaded Stress cables 1, all the prestress cables 1 are distributed along the transverse interval of the truss load-bearing system, one end of the prestressed cables 1 is connected to the top of the longitudinal rear half of the truss load-bearing system, and the other end is connected to the truss load-bearing system The bottom of the vertical front end.

[0040] The hanging basket structure described in this embodiment, the longitudinal rear half of the truss load-bearing system is used for hanging on the construction section, the longitudinal front half of the truss load-bearing system is used for construction, and the second half is used as the load-b...

Embodiment 2

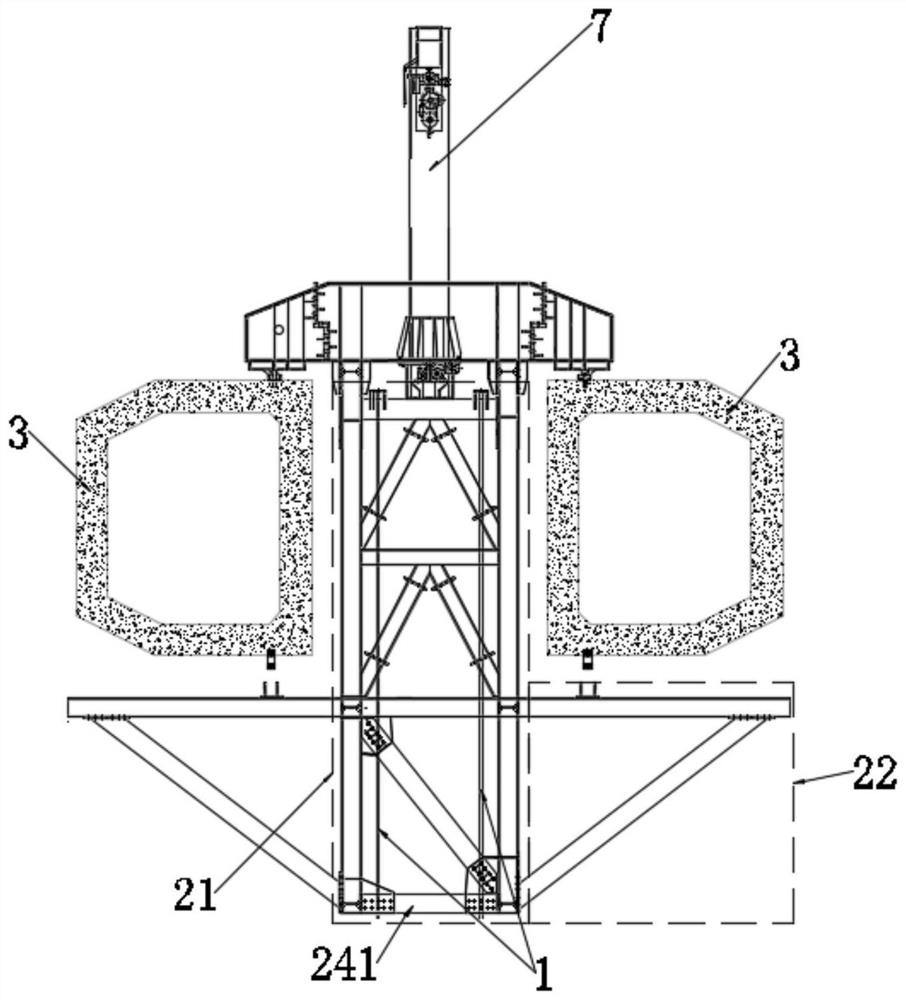

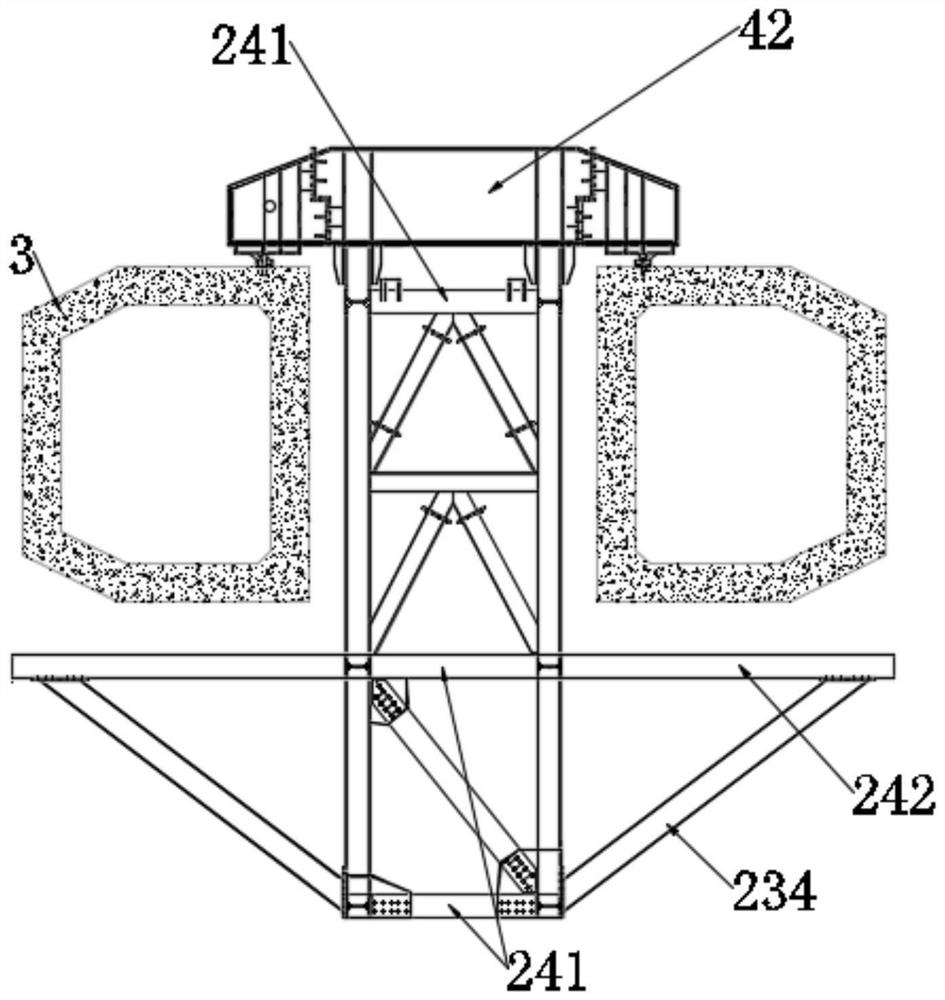

[0045] This embodiment provides a kind of hanging basket structure, and this hanging basket structure can construct the arch rib 3 sections of double arch rib at the same time, as Figure 1-7 As shown, it includes a truss load-bearing system, a walking system, a supporting reaction force system 6 and a thrust system 5, and the walking system, a supporting reaction force system 6 and a thrust system 5 are installed on the truss load-bearing system.

[0046] Such as Figure 1-5 As shown, the truss load-bearing system includes a main truss 21 and cantilevered corbels 22 arranged laterally on both sides of the lower part of the main truss 21, and the upper part of the main truss 21 is used to be placed between two arch ribs 3; The truss load-bearing system composed of the main truss 21 and the cantilevered corbels 22 arranged laterally on both sides, the upper part of the main truss 21 is used to be placed between the two arch ribs 3, forming a cantilever to the lower lateral side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com