Container crane

A technology of container cranes and cranes, which is applied in the direction of cranes, trolley cranes, transportation and packaging, etc., which can solve the problems of underutilized trolley time, high requirements for driver operation skills, and occurrence of waiting time, so as to eliminate waiting for truck collection Time, observation and control are convenient and reliable, and the effect of reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0022] Traditional container cranes generally use a single trolley operation method, that is, after the main trolley lifts the container from the container ship, it runs along the rail of the crane girder to the top of the collection truck, and then lowers the container to the collection truck. In addition to the road return, there is still waiting time for the main car caused by the absence of the collection truck. The longer reciprocating stroke of the main trolley and the waiting time caused by the failure of the truck to arrive reduce the operating efficiency of the crane.

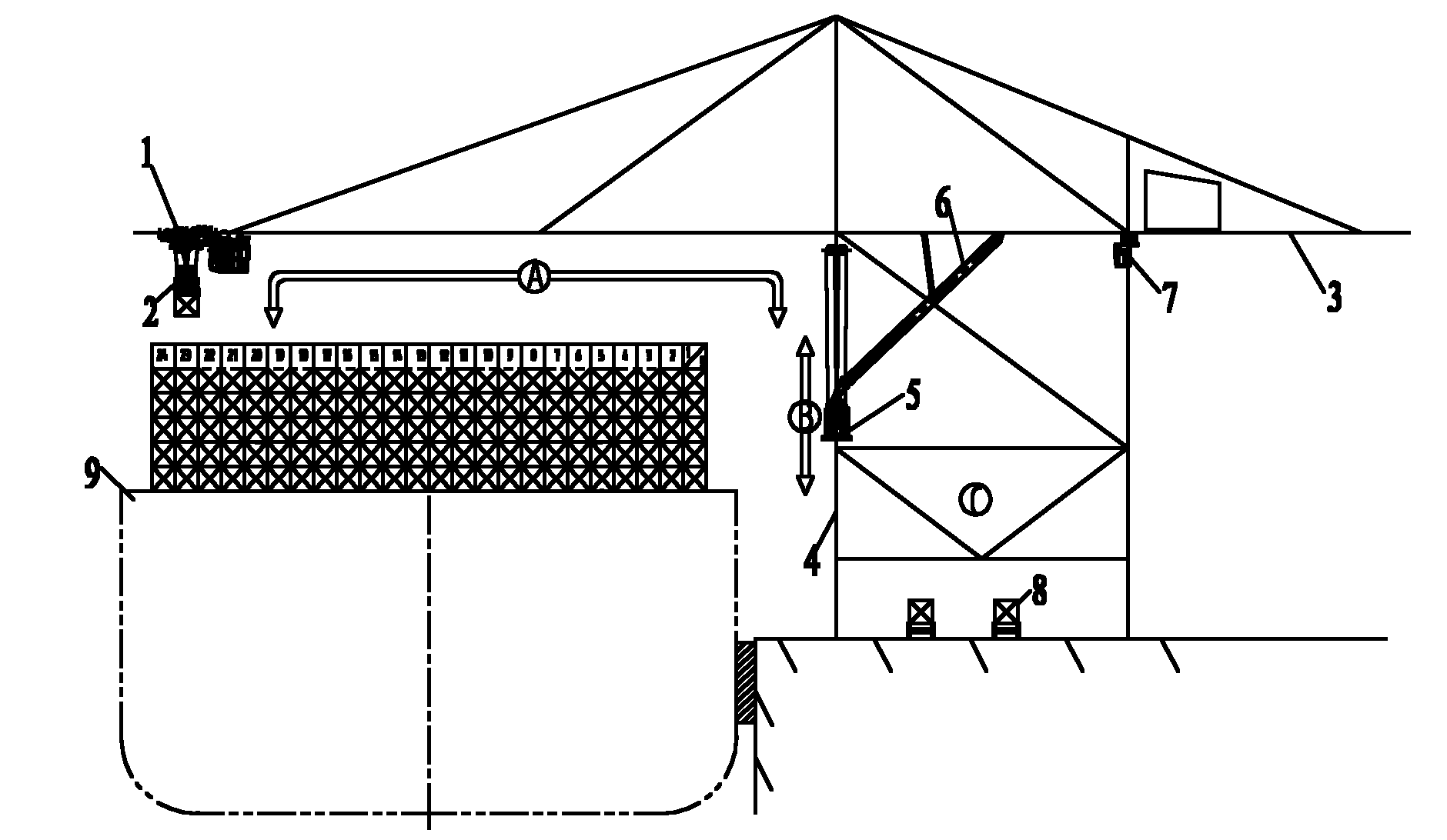

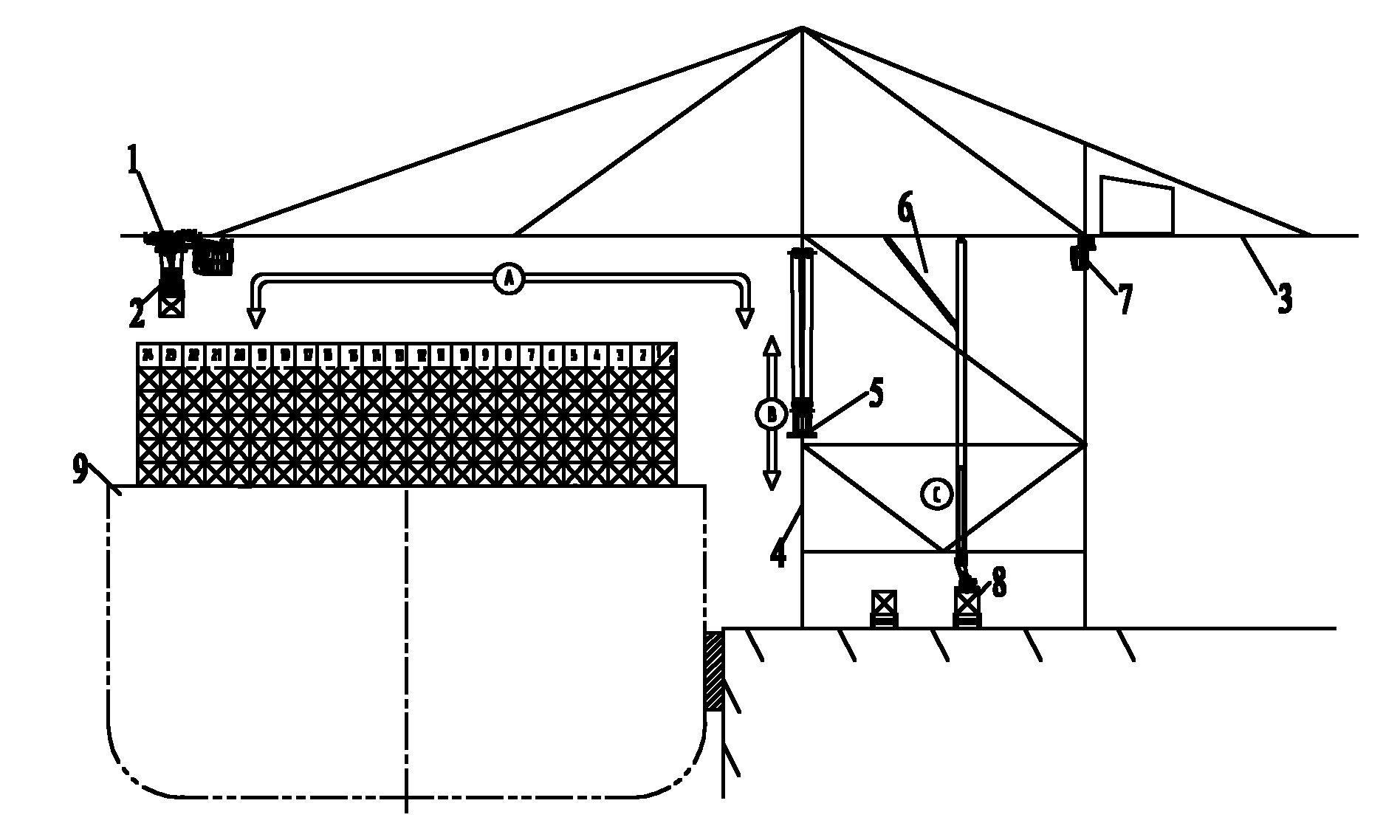

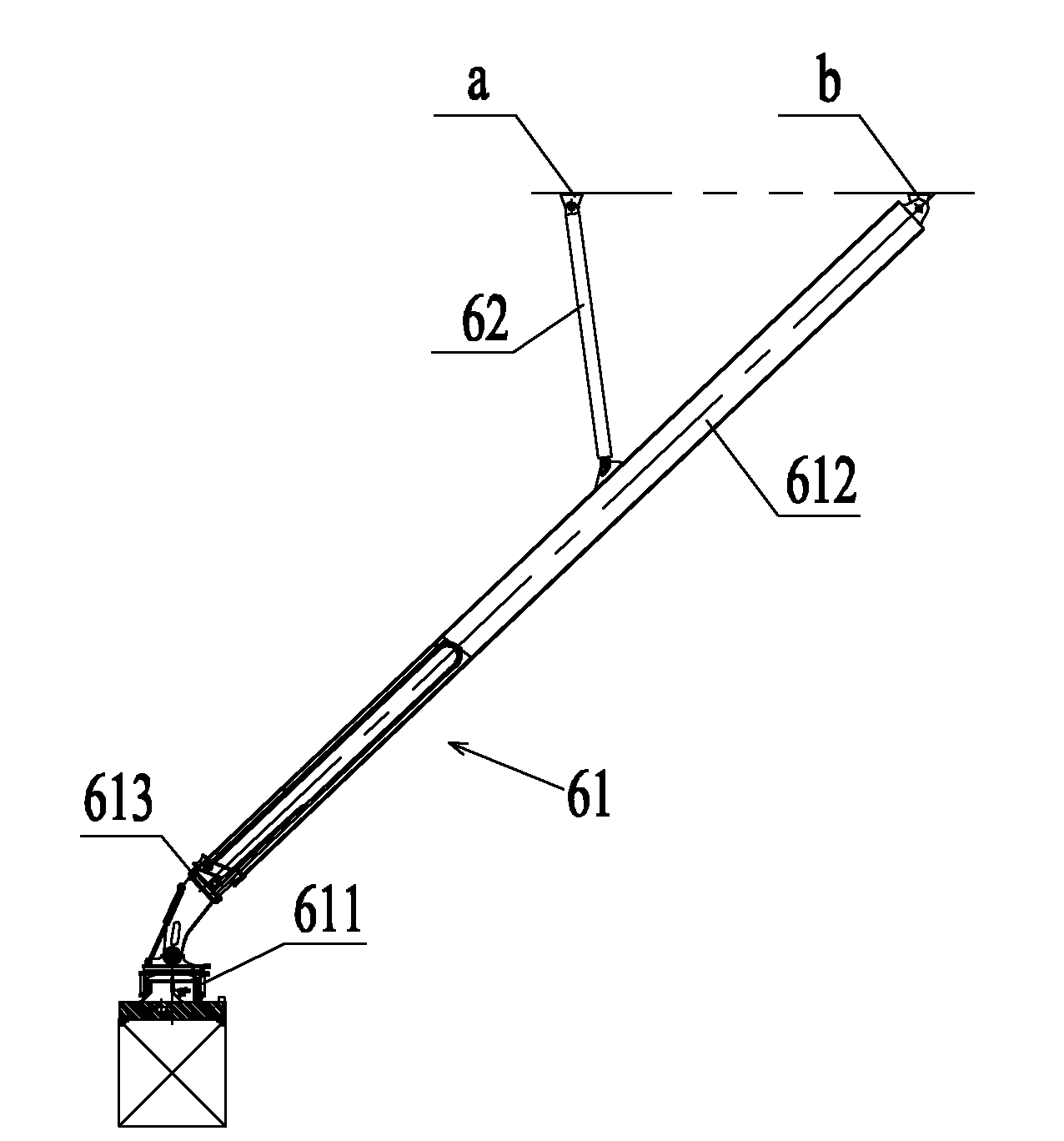

[0023] Such as figure 1 As shown, the container crane according to the embodiment of the present invention includes a cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com