Multi-type packaging integrated machine and packaging method thereof

A multi-type, all-in-one technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve problems such as narrow application scope, long overall equipment length, and materials that cannot be used with flexible materials, saving costs, improving applicability, Distribute technology for quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

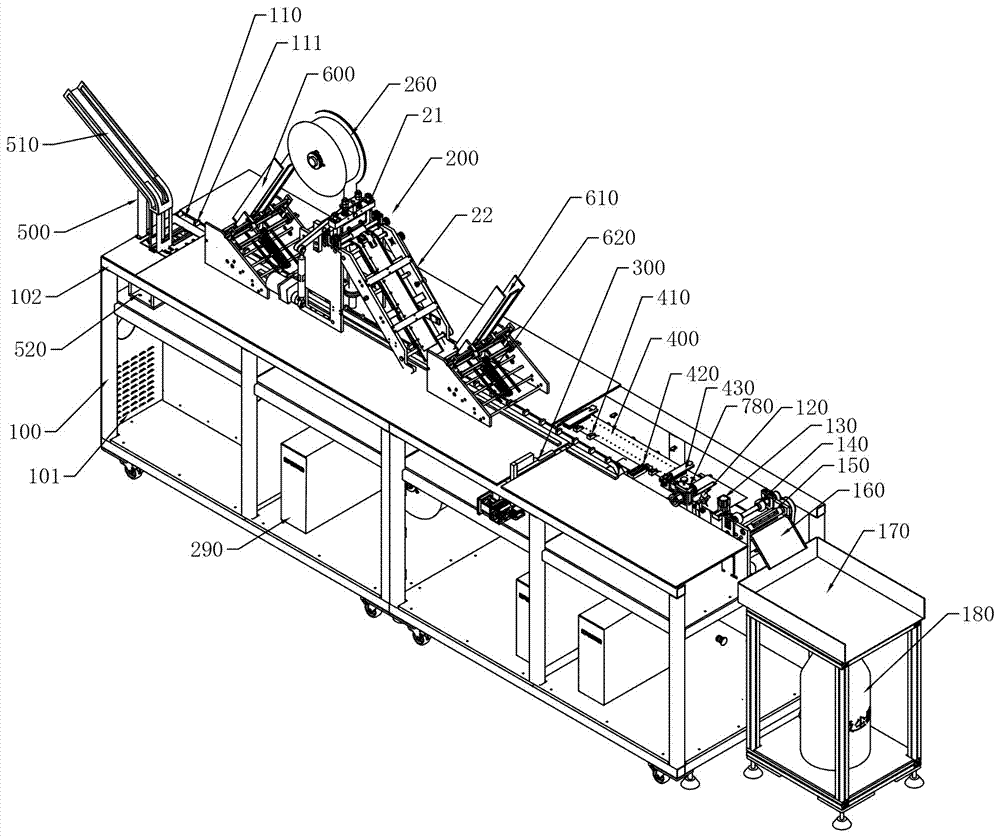

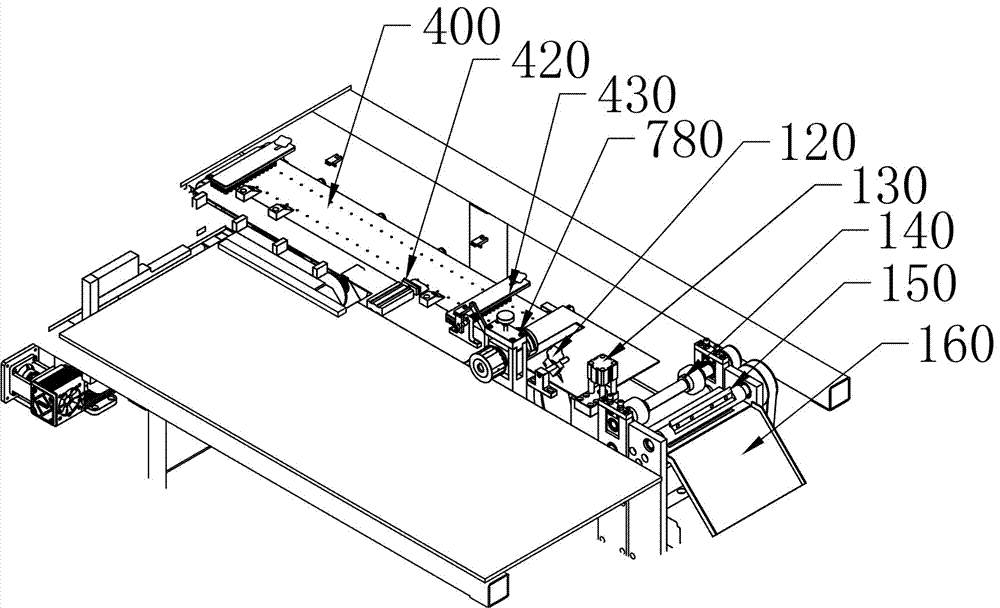

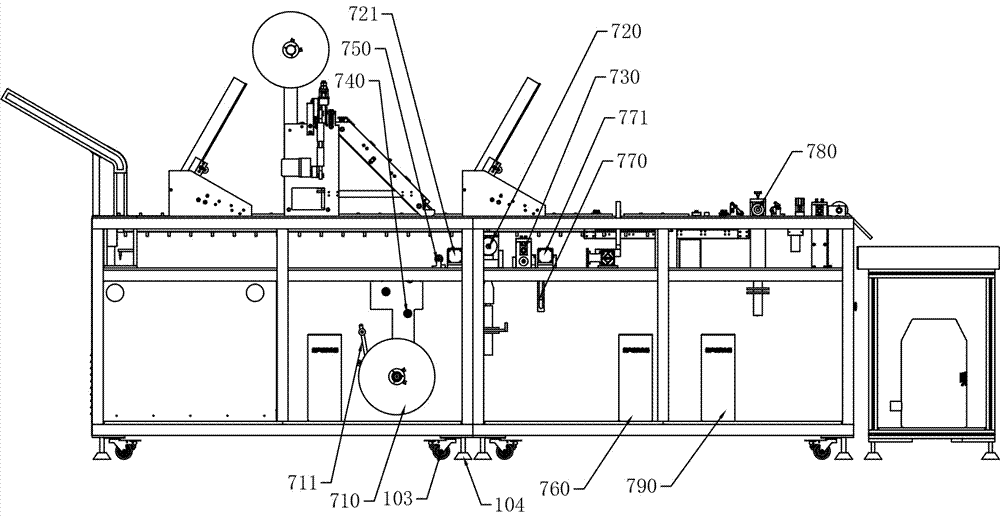

[0085] Such as figure 1 and Figure 4 As shown, a multi-type packaging all-in-one machine includes a frame 100 and a conveyor belt 110 for conveying materials. The conveyor belt 110 is installed on the frame 100, and several sequentially connected Limiting pieces 111, a limiting groove for placing materials is formed between every two limiting pieces 111.

[0086] The frame 100 is spliced into three layers from bottom to top through the detachable connecting plate 101 and the square tube 102, which are respectively the lower layer, the middle layer and the upper layer. device, a material pushing device for pushing materials into the packaging film, and a packaging device for sealing the packaging film; the frame in this patent embodiment adopts an upper, middle and lower three-layer structure, and is welded by square tubes 102 Each layer is laid with steel plates of corresponding thickness for placing different parts. At the same time, the whole frame is composed of front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com