Intermediate track and auxiliary device transportation system

An intermediate track and auxiliary device technology, applied in the field of wheel-rail railways, can solve the problems that wheel-rail railways cannot solve the horizontal and vertical forces, etc., and achieve the effects of improving snaking motion, reducing track vibration and noise, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

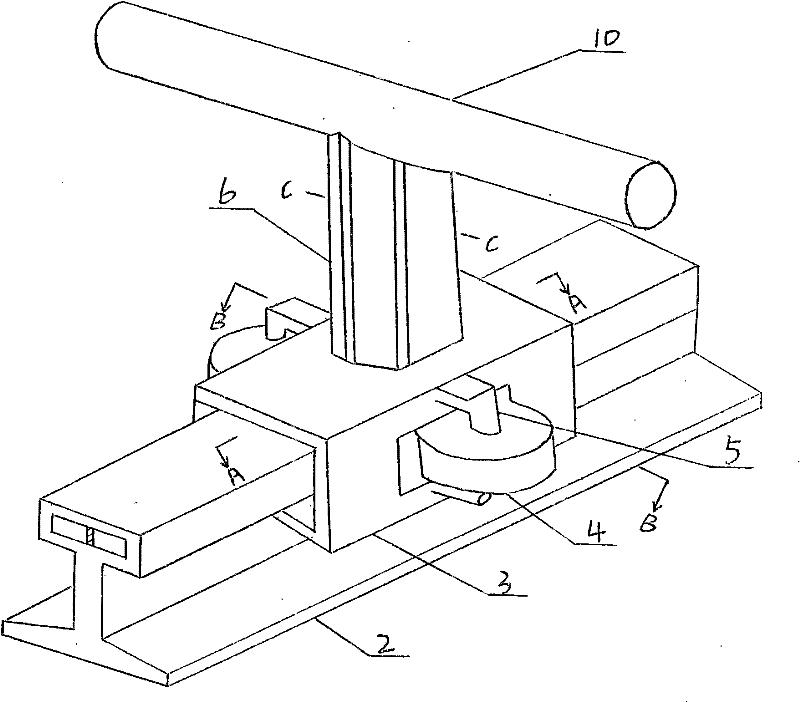

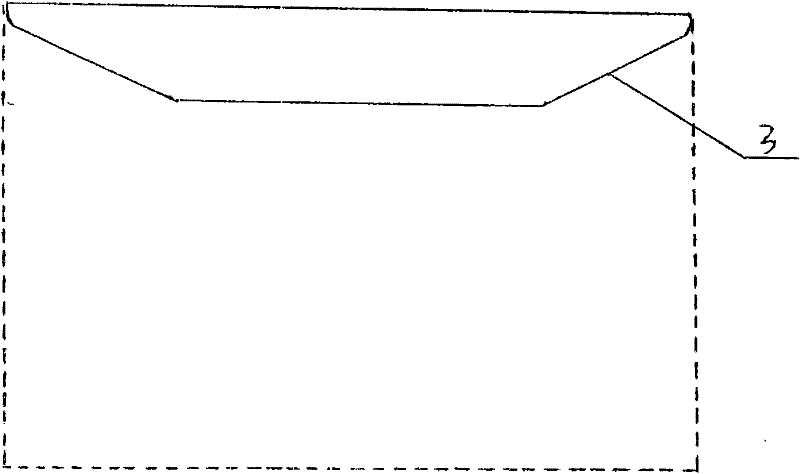

[0075]The hook (3) and the guide wheel axle (5) should be made of alloy material or carbon fiber with higher strength to ensure sufficient mechanical properties and miniaturization of volume. The width of both sides of the middle track (2) should be greater than the vertical distance between the lowermost end of the inner wall of the hook (3) and the center post (2) of the middle track.

[0076] The lateral distance between the connecting rod (9) and the notch of the outer cylinder (7) is usually 4-8mm, and this distance plays a role in limiting the lateral displacement of the wheel set during the running of the train.

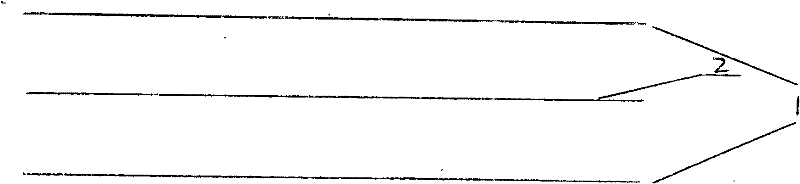

[0077] The two ends of the connecting rod (6) are designed to be nose-shaped and play the role of reducing air resistance.

[0078] The height of the lowest end of the controller device is usually between 30mm above the track and the middle part of the sleeper below the top surface of the rail. If it is considered that the train passes through the fork without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com