Welding method for air purifier honeycomb mesh

An air purifier and welding method technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment and other directions, can solve the problems of product defects, increased production cost, low production efficiency, etc. The effect of labor cost reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

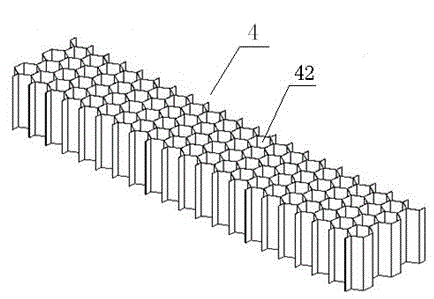

[0040] Embodiment 1: as Figure 1 to Figure 4 , Figure 13 As shown, the welding method of the honeycomb mesh of the air purifier includes the following steps:

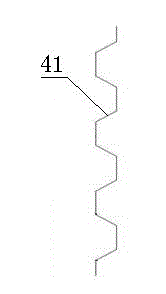

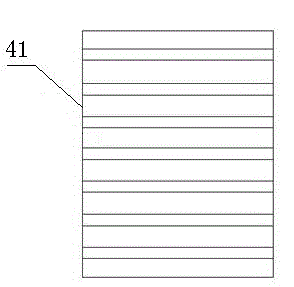

[0041] The first step is to clean the galvanized sheet: remove the sundries on the surface of the galvanized sheet 41 which is continuously bent forward and reverse trapezoidally.

[0042] The second step, silk screen printing solder paste: on the bonding surface of the galvanized sheet 41 which is continuously bent in a trapezoidal front and back, the solder paste is silk screen printed on each bonding surface at three places. The grade of the solder paste is NC747-7B0C2, the melting point is 183°C, the alloy composition is Sn63 / Pb37, and it is a product produced by SOLCHEM. Solder paste is also called solder paste, the English name is solder paste, gray paste. Solder paste is a new type of soldering material that emerged with Surface Mount Technology (SMT) in the 1970s. It is composed of solder powder, flux and ...

Embodiment 2

[0051] Embodiment 2: The welding method of its air cleaner honeycomb net is mostly the same as the method described in Example 1, except that in the fourth step of heating and welding, the heating temperature of the air cleaner honeycomb net 4 The temperature is 250°C, and the holding time is 3 minutes.

Embodiment 3

[0052] Embodiment 3: The welding method of its air cleaner honeycomb net is mostly the same as the method described in Example 1, except that in the fourth step of heating and welding, the heating temperature of the air cleaner honeycomb net 4 The temperature is 255°C, and the holding time is 2.5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com