High-efficiency energy-saving bending machine

A high-efficiency energy-saving bending machine technology, applied in the field of bending devices, can solve problems such as unfavorable production efficiency, cumbersome steps, and complex structure, and achieve the effect of enhancing guiding and supporting functions, reducing cumbersomeness, and increasing the force-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

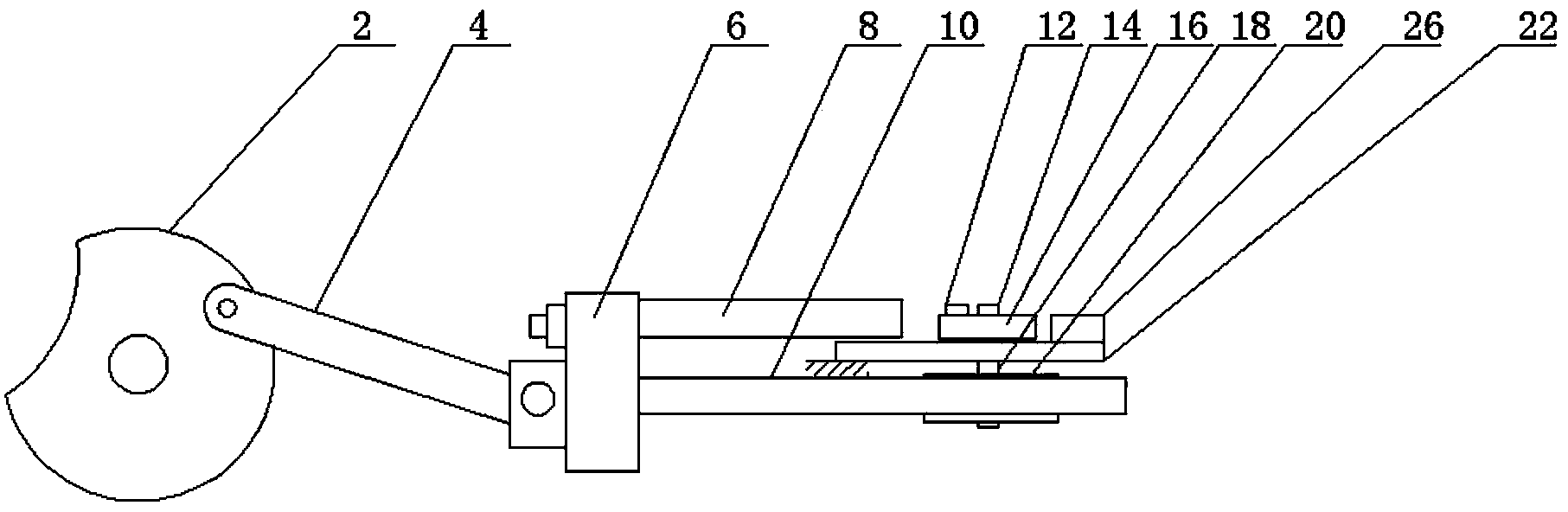

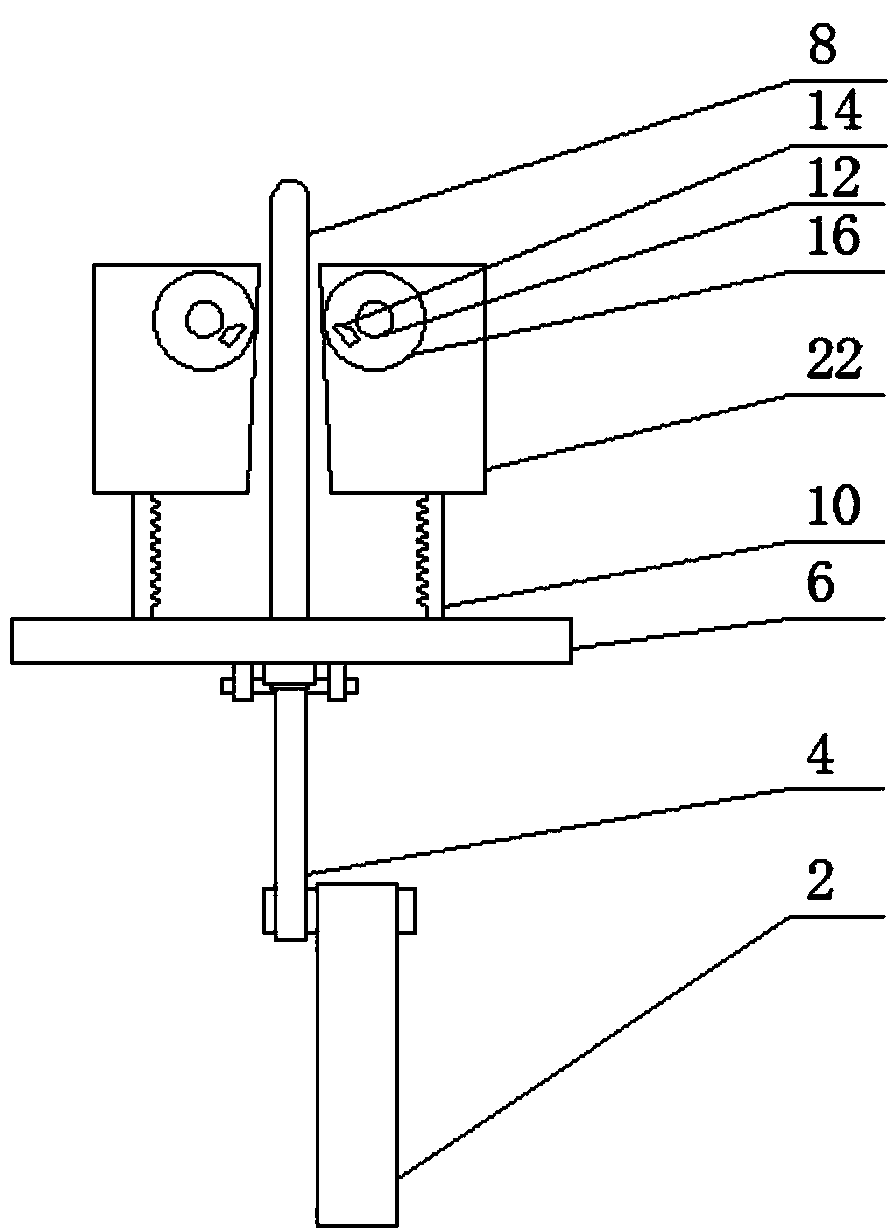

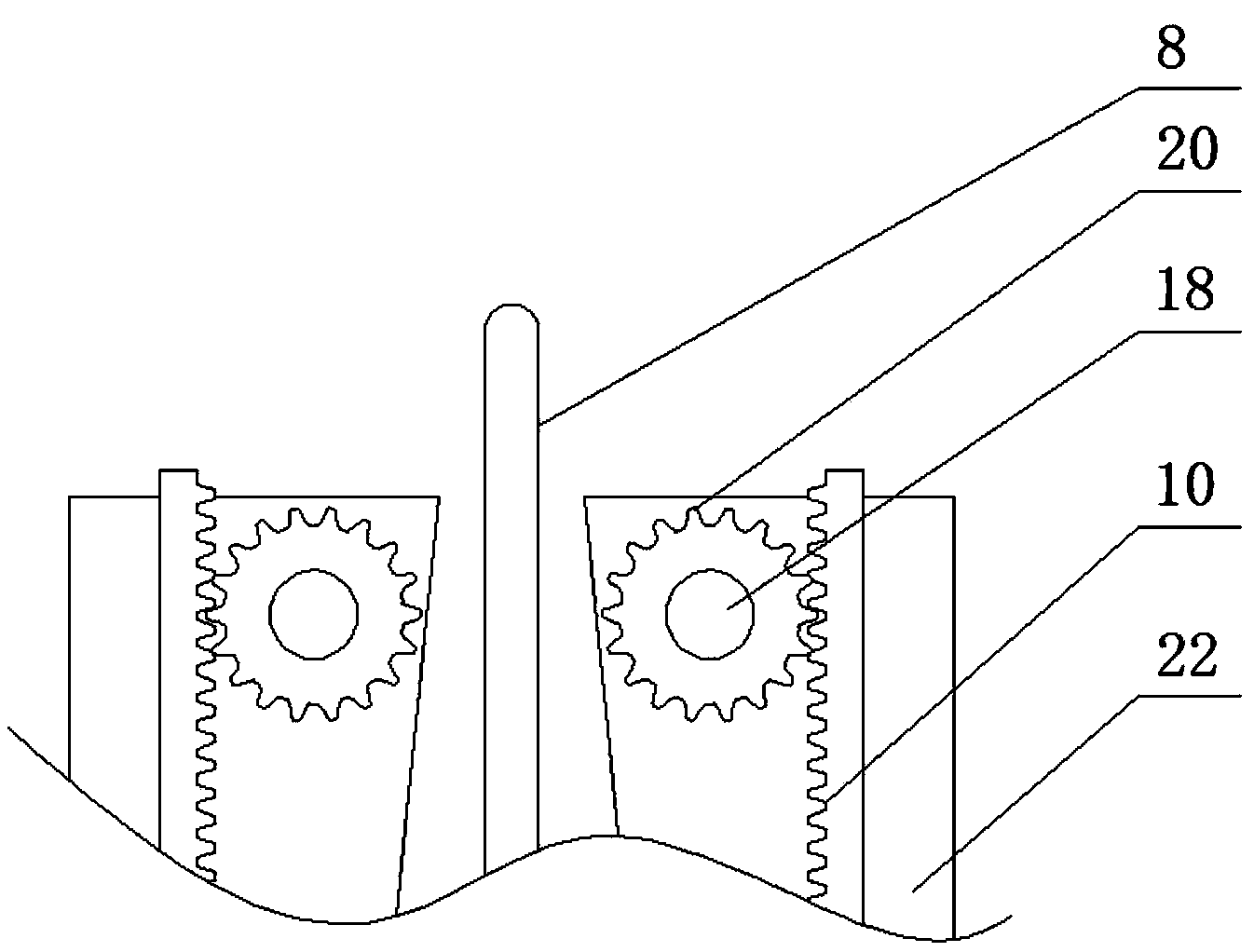

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Figure 1 to Figure 3 It is the first embodiment of the present invention, which includes two horizontal baffles 26 arranged in gaps, behind each baffle 26 there is a turntable 16 driven to rotate by a power device, and the upper surface of the turntable 16 is provided with the turntable 16. The concentric and columnar first bump 14 and the second bump 12 eccentrically arranged on the turntable 16 are fixedly connected to the transmission shaft 18 under the turntable 16, and a fixed plate 22 is also provided under the turntable 16, and the transmission shaft 18 is Through the fixed plate 22 and fixed on the fixed plate 22 by bearings, there are also gears 20 fixedly connected to the two transmission shafts 18 below the fixed plate 22, and the gears 20 are provided with racks 10 meshing with them. A push rod 8 is also arranged between the two rotating disks 16 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com