Roller-cone polycrystalline diamond compact (PDC) two-stage cutting compound drill bit

A compound drill bit and roller cone technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., can solve the problem of slowing down of mechanical drilling speed of PDC drill bits and roller cone bits, increasing the investment and cost of surface pump equipment, cutting debris return, etc. Insufficient drainage space and other problems, to achieve the effect of realizing drilling efficiency, improving well deviation control ability, and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

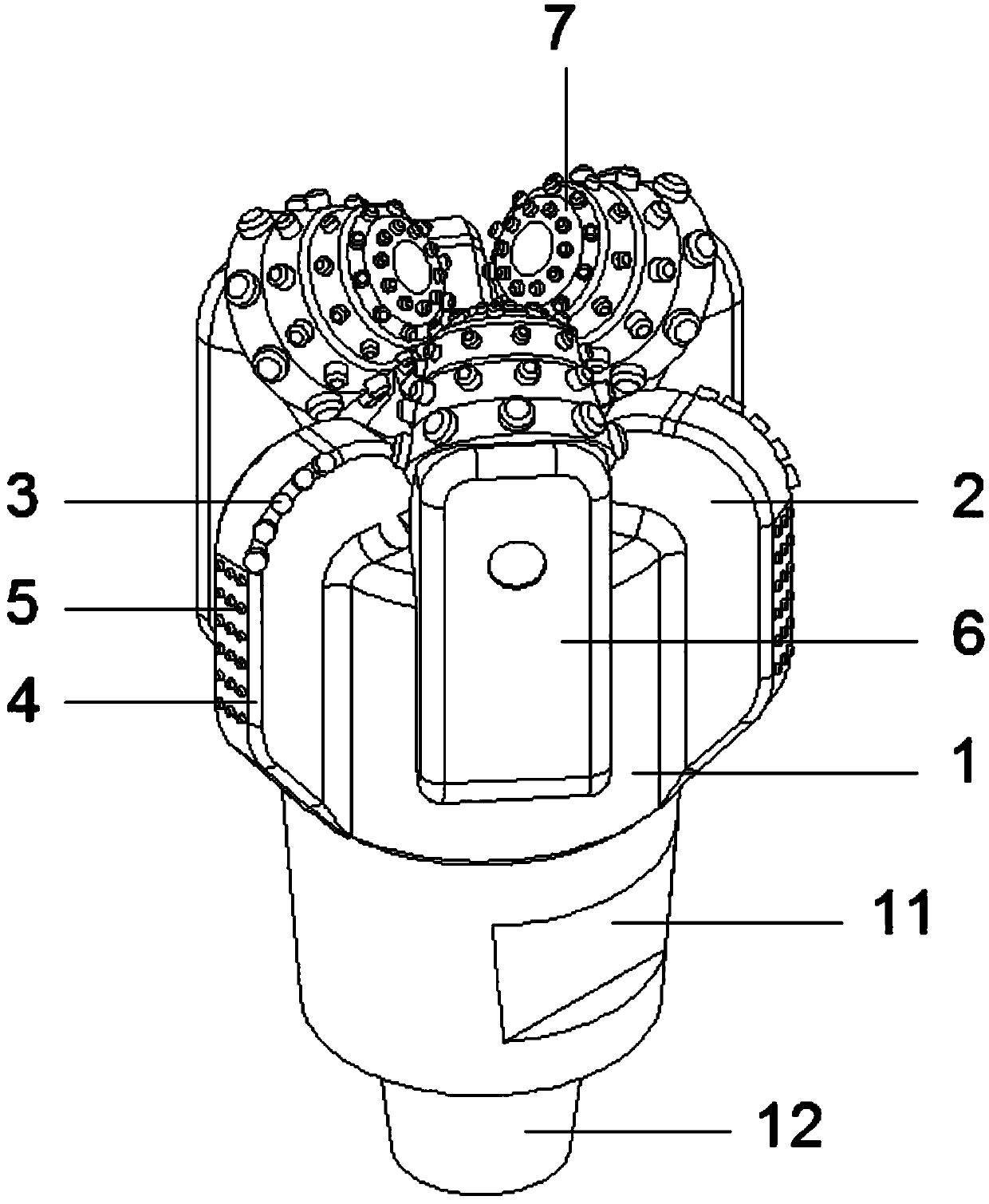

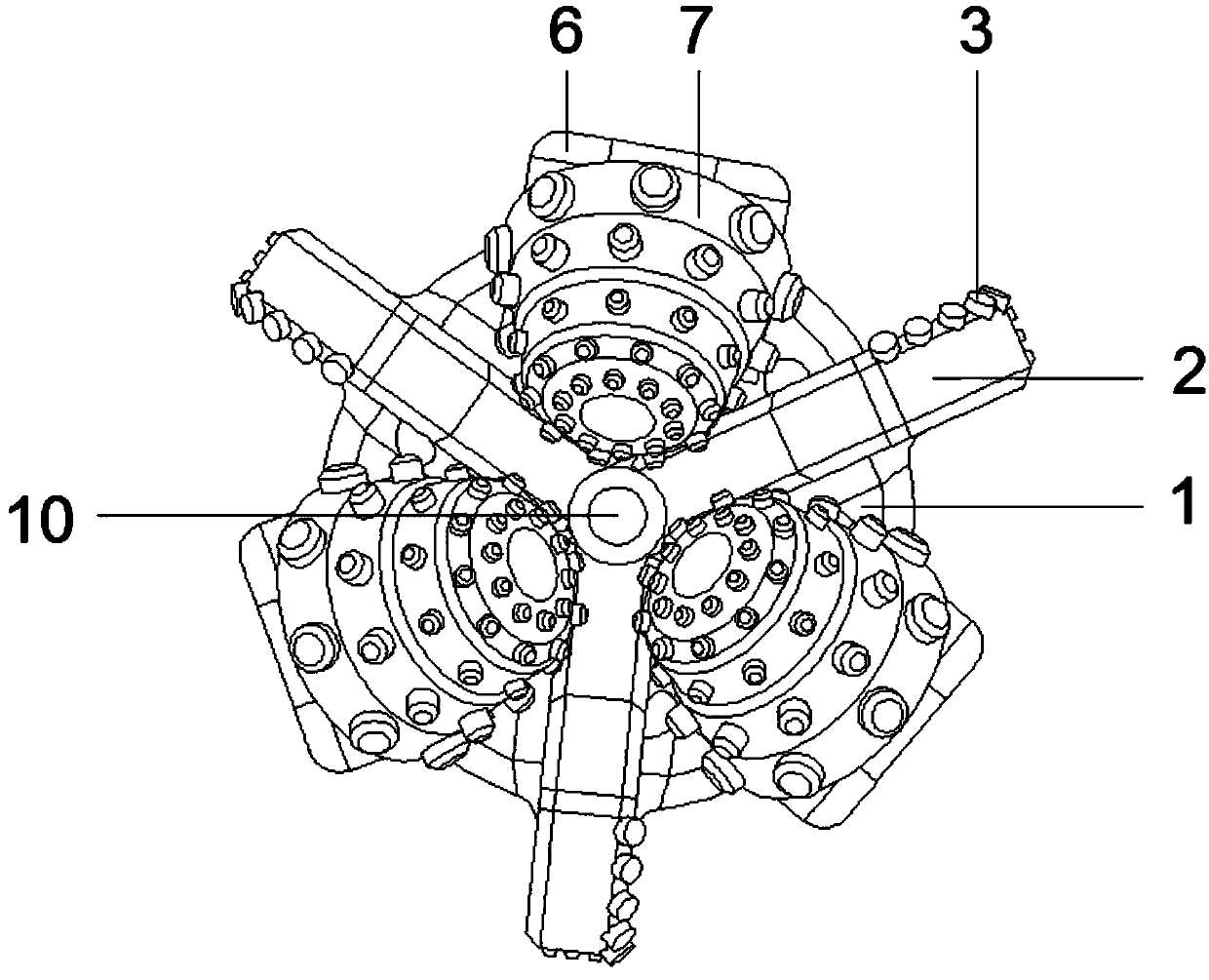

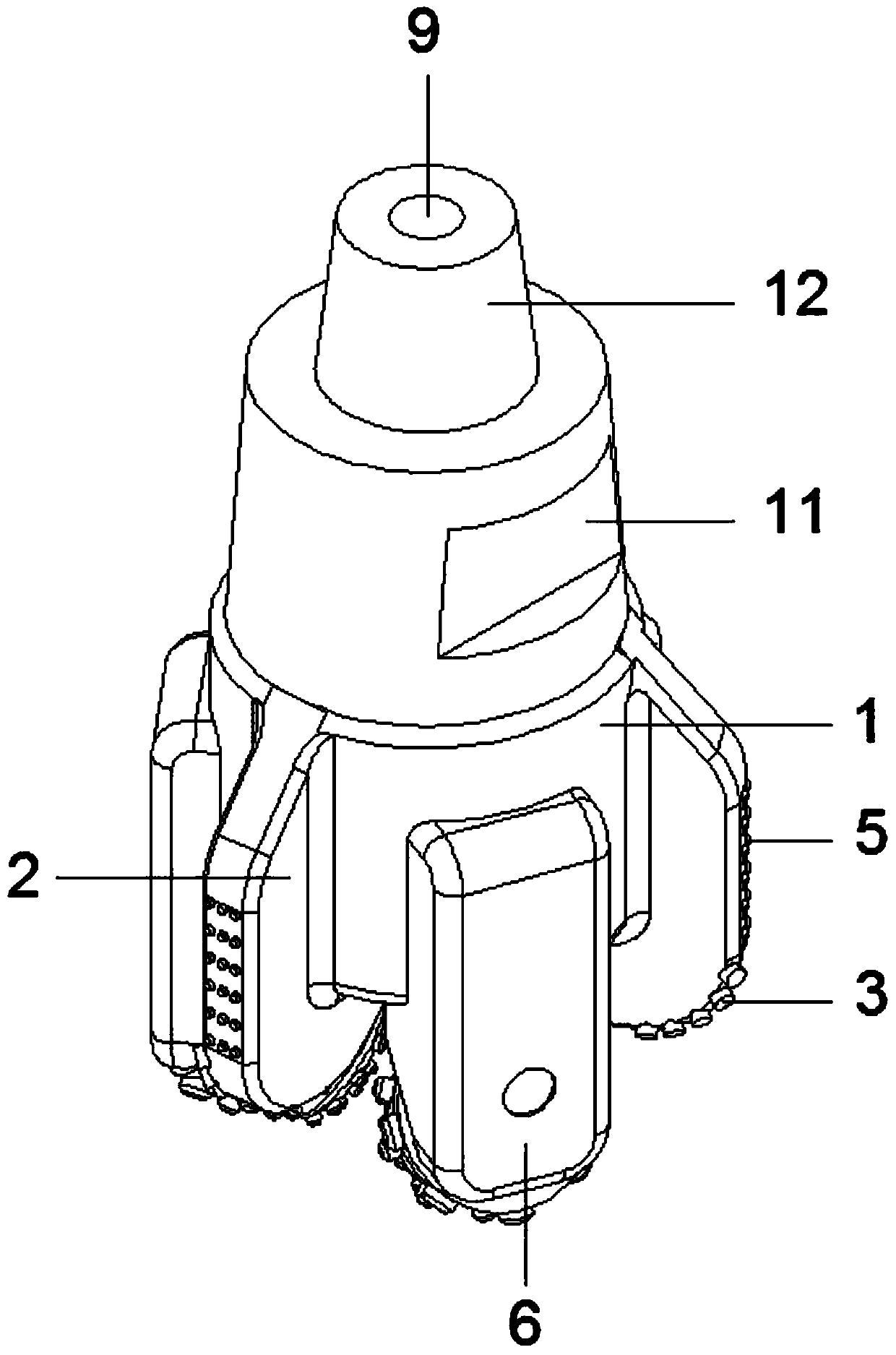

[0035] A roller cone PDC two-stage cutting compound drill bit, comprising: PDC bit body 1, blade 2, cutting teeth 3, gauge part 4, gauge teeth 5, oil storage chamber 6, cone 7, teeth 8, flow channel 9. Water eye 10, shackle groove 11, screw thread 12; the blade 2 is set on the top of the PDC bit body 1, and the blade 2 and the PDC bit body 1 are of an integrated structure; the cutting teeth 3 are welded and installed on the blade 2 one side of the top; the gauge part 4 is arranged on the outside of the blade 2, and the gauge part 4 is connected with the blade 2 by welding; the gauge teeth 5 are welded and installed on the outer wall of the gauge part 4; The oil cavity 6 is arranged on the top of the PDC bit body 1, and the oil storage cavity 6 is connected with the PDC bit body 1 by welding; the cone 7 is installed on the top of the oil storage cavity 6; the outer wall of the tooth 8 is welded and mounted on the cone 7 Above; the flow channel 9 is set through the middle positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com