Corn stigma peeling device

A peeling device and technology of corn silk, which is applied in the direction of agricultural machinery and implements, applications, harvesters, etc., can solve the problems of reducing the drying effect of corn cobs, shortening the shelf life of corn cobs, and easy mildew of corn cobs, so as to improve the peeling effect, Improves air-drying effect and increases pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

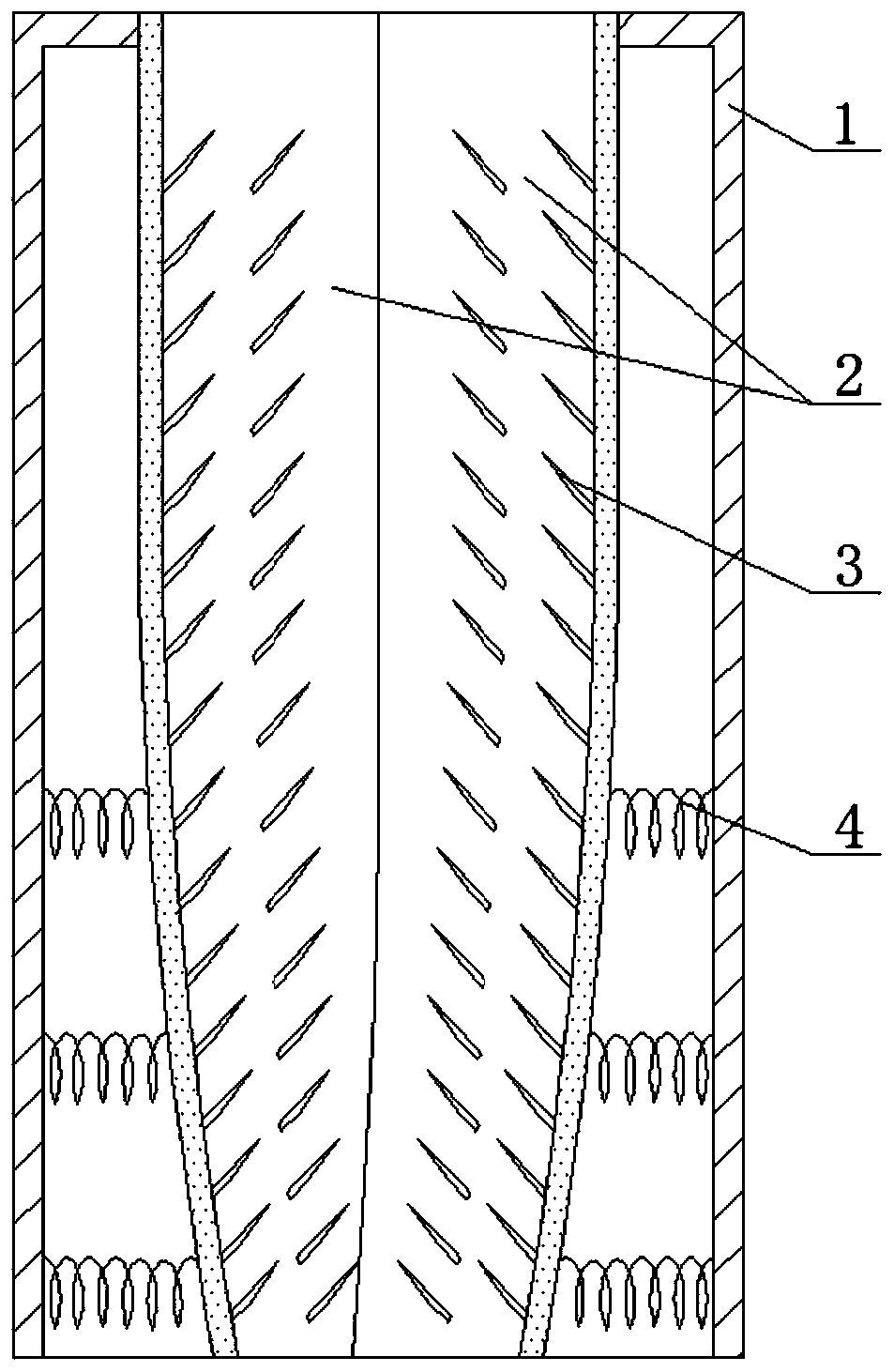

[0035] A corn silk stripping device, such as figure 1 As shown, it includes a peeling cylinder, a support cylinder 1, spikes 3 and an elastic member 4. The peeling cylinder is a cylindrical structure surrounded by four arc-shaped plates 2. The arc-shaped plates 2 are thin-walled plates, which can make the arc-shaped plates 2 It has elasticity, so as to be more adaptable to deformation. The support tube 1 is set outside the peeling tube, and the upper end of the support tube 1 is hinged with the upper end of the arc plate 2. There are multiple spikes 3, and the spikes 3 are arranged on the arc plate 2 away from the On one side of the support cylinder 1, the spikes 3 are welded and fixed to the arc-shaped plate 2. The end of the spikes 3 close to the arc-shaped plate 2 is lower than the end of the spikes 3 away from the arc-shaped plate 2. Multiple spikes 3 are on the arc-shaped plate. Evenly distributed on 2, the elastic member 4 is arranged between the support cylinder 1 and t...

Embodiment 2

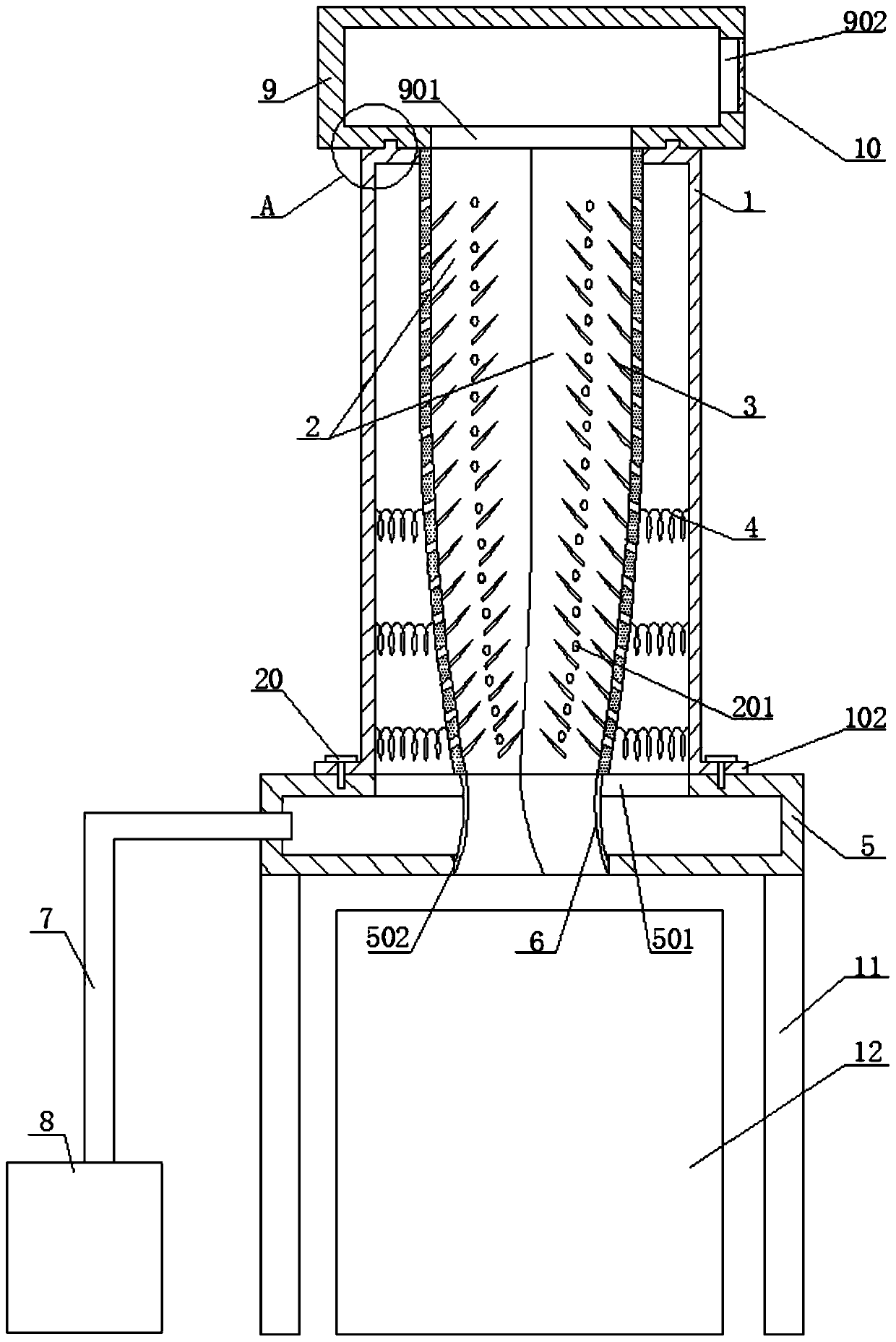

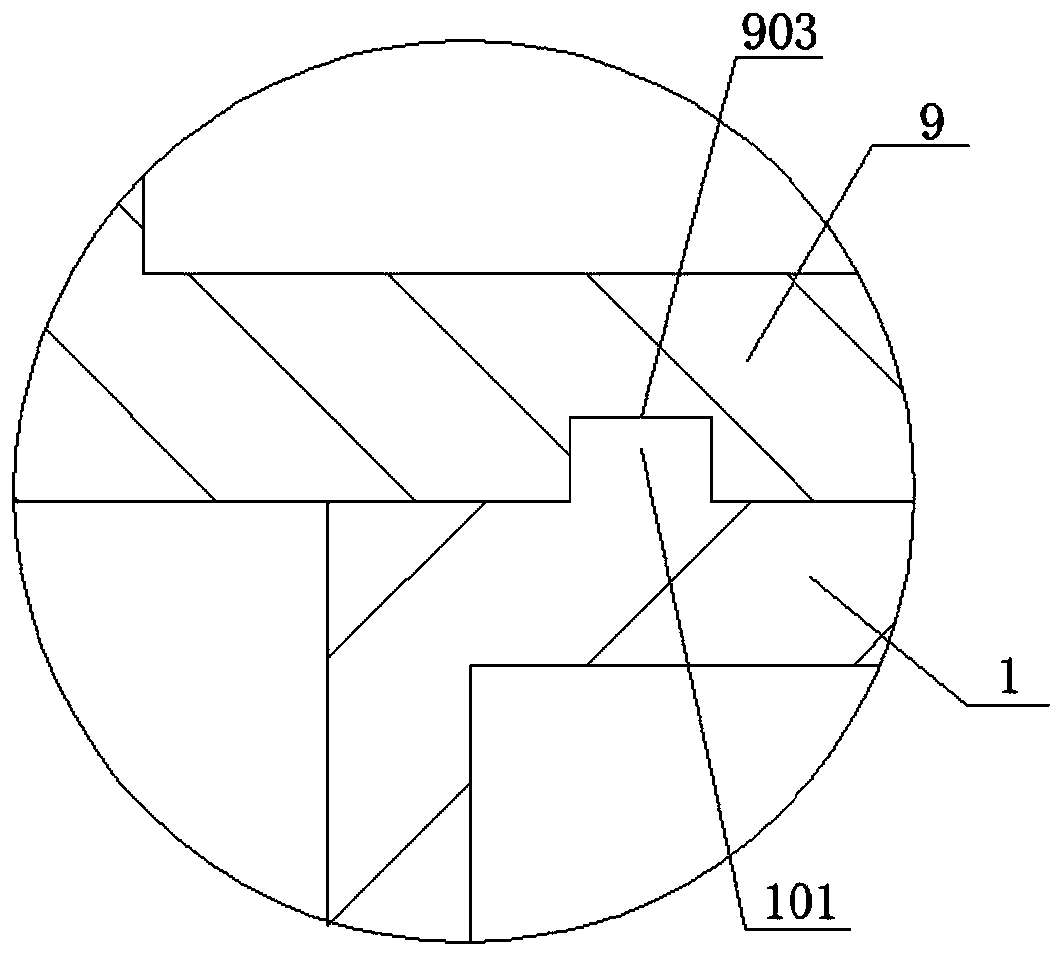

[0039] This embodiment 2 is the same as embodiment 1, the difference is that, as figure 2 and image 3 As shown, a kind of corn silk peeling device of present embodiment 2 also comprises corn silk collecting device, and corn silk collecting device comprises first box body 5, fan 8 and second box body 9, and described arc plate 2 is provided with A plurality of air intake holes 201, the plurality of air intake holes 201 are evenly distributed on the arc-shaped plate 2, and the end of the air intake hole 201 close to the axis of the support cylinder 1 is higher than the end of the air intake hole 201 away from the axis of the support cylinder 1;

[0040] The first box body 5 is arranged below the support cylinder 1, the first box body 5 lower end is covered with a connecting ring 102, the first box body 5 and the connecting ring 102 are welded and fixed, the connecting ring 102 is provided with a first threaded hole, the first The upper plate of the box body 5 is provided with...

Embodiment 3

[0046] This embodiment 3 is the same as embodiment 2, the difference is that, as Figure 4 and Figure 5 Shown, a kind of corn whisker stripping device of present embodiment 3 also comprises corn pushing device, and corn pushing device comprises the 3rd box body 13, push rod 14, sleeve 15 and driving device, and the 3rd box body 13 is located at the second Above the box body 9, a second positioning block 1303 is provided below the third box body 13, and the second positioning block 1303 is welded and fixed with the third box body 13, and the upper end surface of the upper plate of the second box body 9 is provided with a second positioning block. Positioning groove 905, the second positioning groove 905 cooperates with the second positioning block 1303, when installing the third box body 13, by inserting the second positioning block 1303 into the second positioning groove 905, the third box body 13 and the second The box body 9 is fixed together, the upper plate of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com