Tip-extension type deep hole boring cutter rod

A telescopic and boring tool bar technology, which is applied in the direction of boring bars, tool holder accessories, and tools used in lathes, etc., can solve the problems of inability to perform cutting processing, affecting the processing of long-axis parts, and large length-to-diameter ratio of the tool bar. , to achieve the effect of low manufacturing cost, stable processing state and guaranteed rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

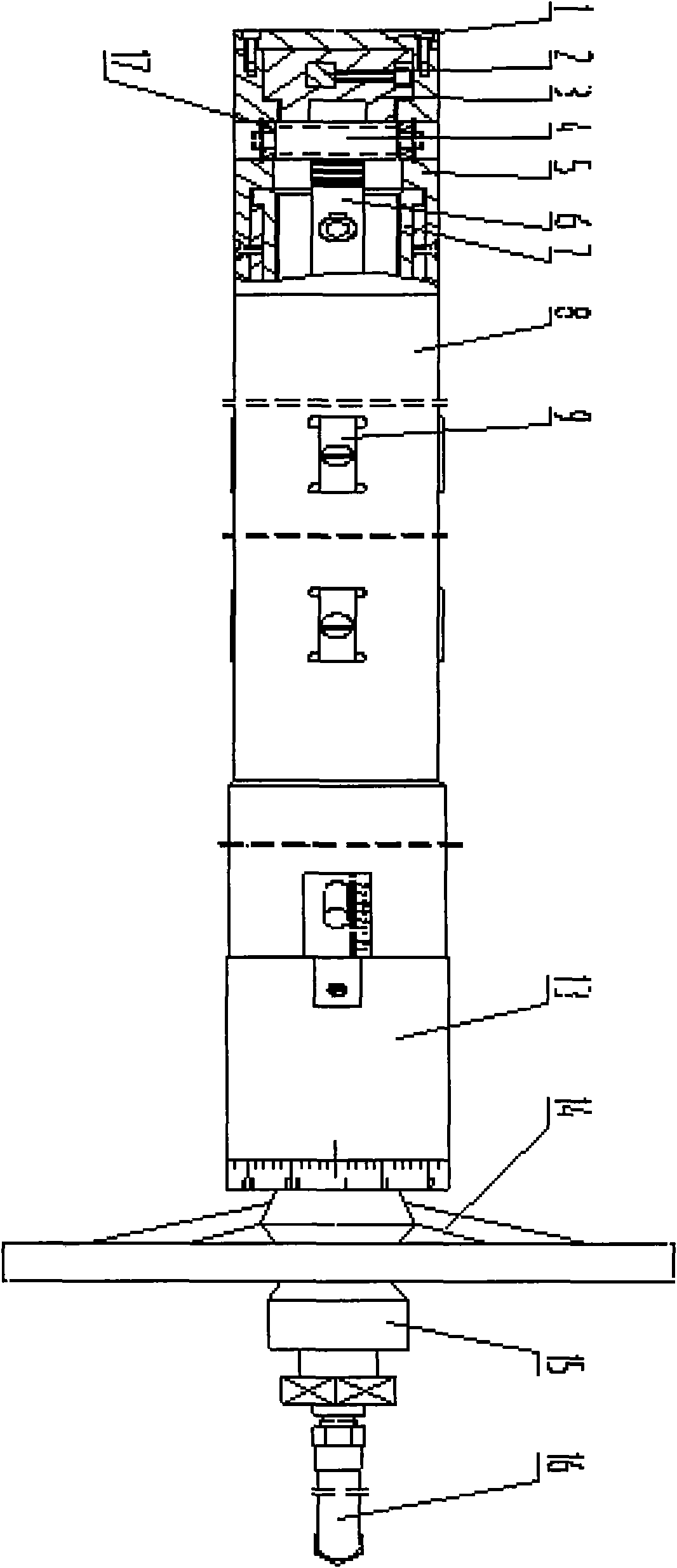

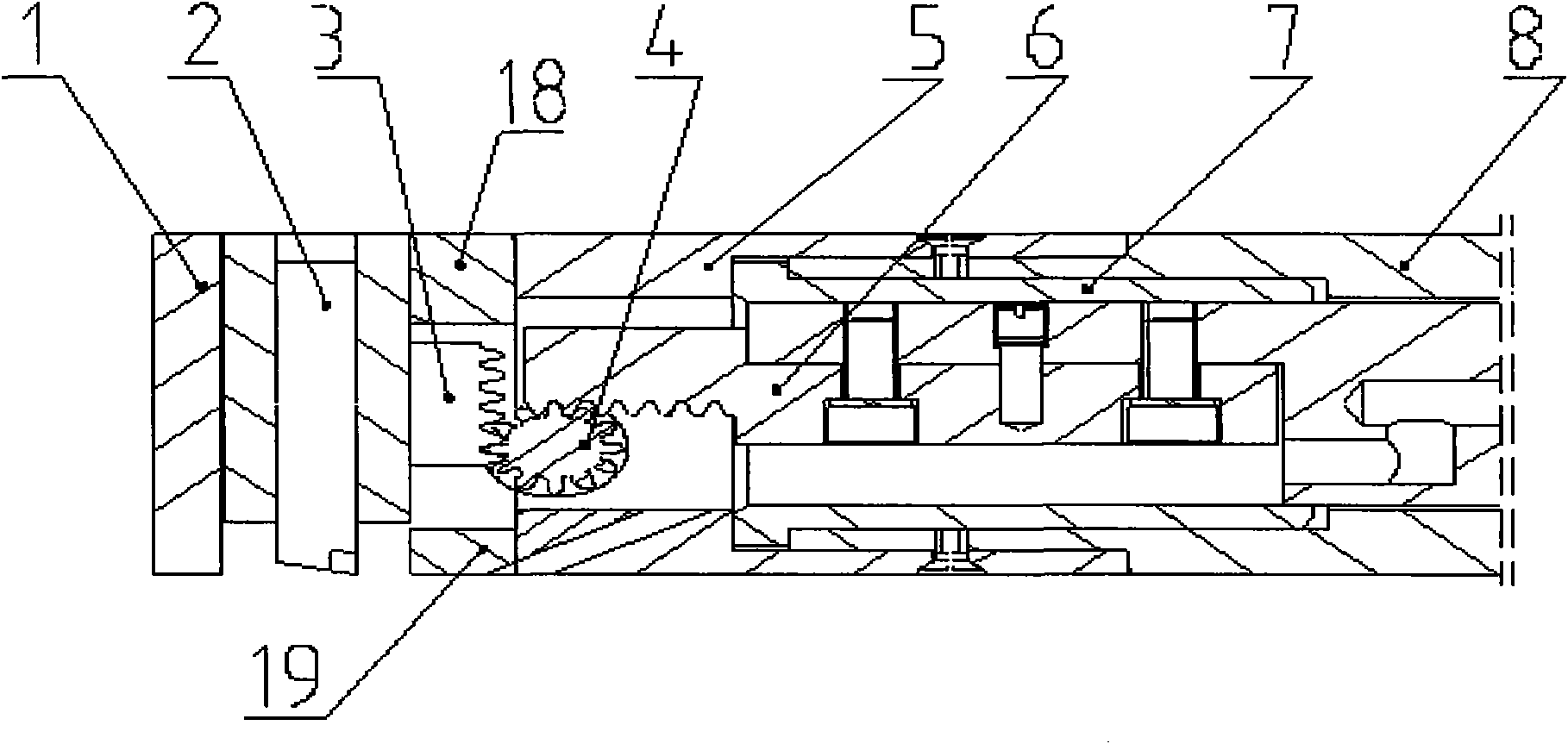

[0054] This embodiment is a telescopic deep-hole boring tool bar for machining a deep hole of a long-axis part, including an outer tool bar system, an inner transmission system and a cooling system.

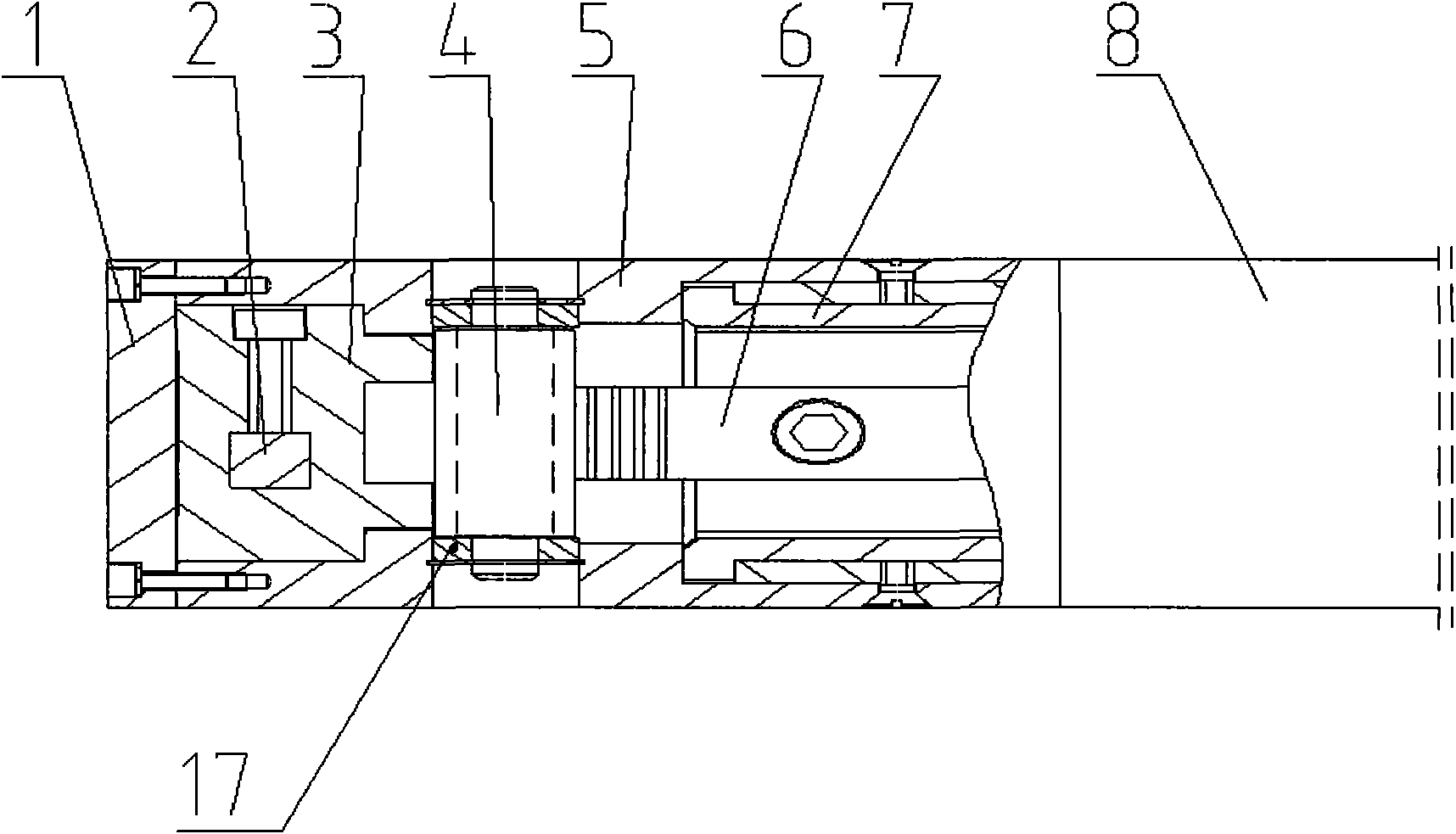

[0055] The outer knife bar system includes a gland 1, a gear mounting seat 5, an outer knife bar 8, a first copper sleeve 7, a second copper sleeve 12, a guide block 9, a bearing seat 13, a first baffle plate 18 and a second baffle plate 19 .

[0056] Gland 1 is a circular plate, the outer diameter of which is the same as that of outer cutter bar 8; two groups of connection holes are symmetrically distributed on the outer edge of gland 1, and there are two positioning pin holes on the center line of gland 1, and the two Two positioning pin holes are symmetrically distributed on the outer edge of the gland 1; the centers of the connecting holes and the positioning pin holes are on the same line, and the positioning pin holes are located between the connecting holes.

[0057] as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com