Pneumatic tire

A pneumatic tire, tire technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., to achieve the effect of balancing driving stability on dry roads, ensuring drainage, and balancing driving stability on wet roads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

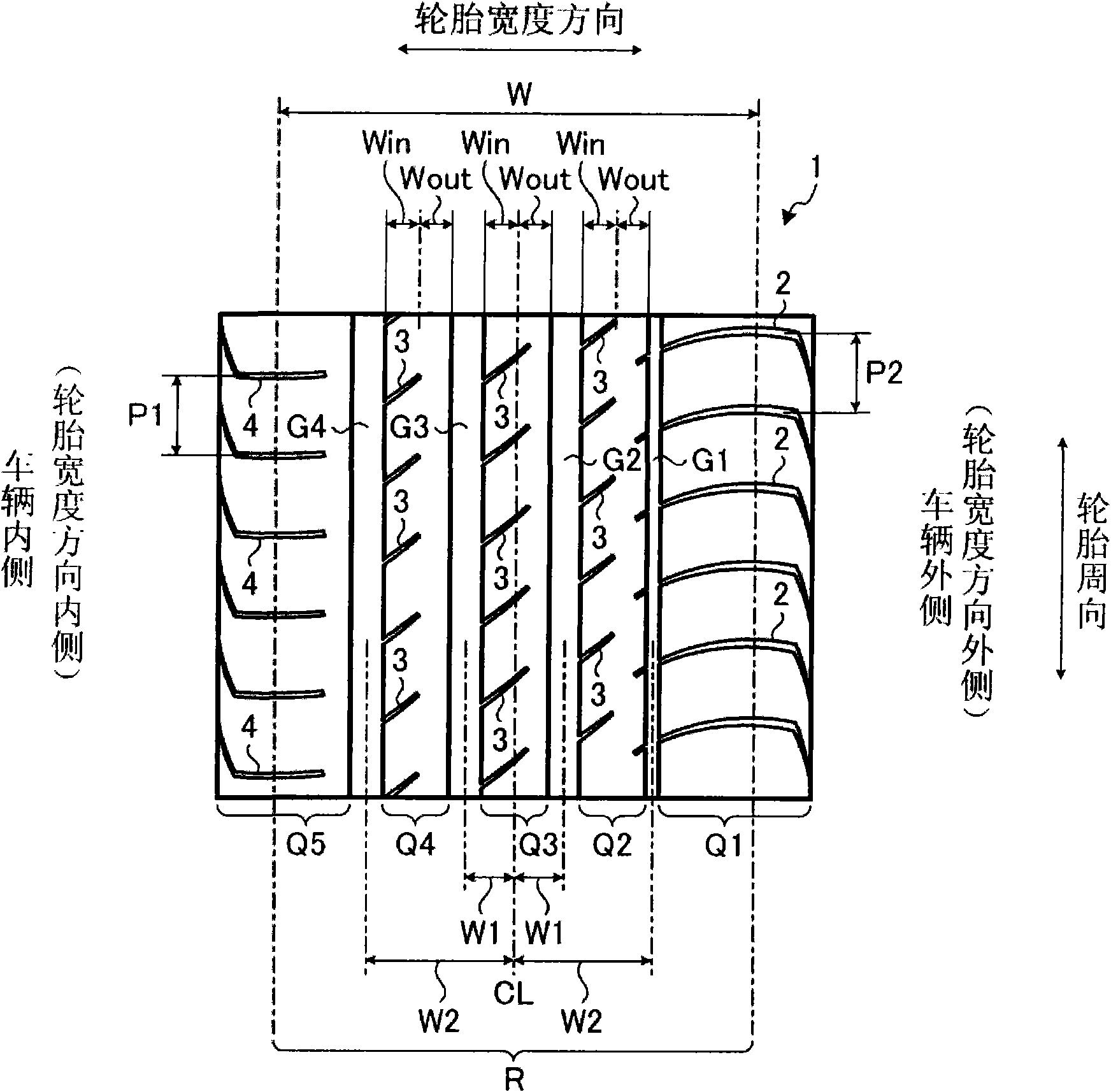

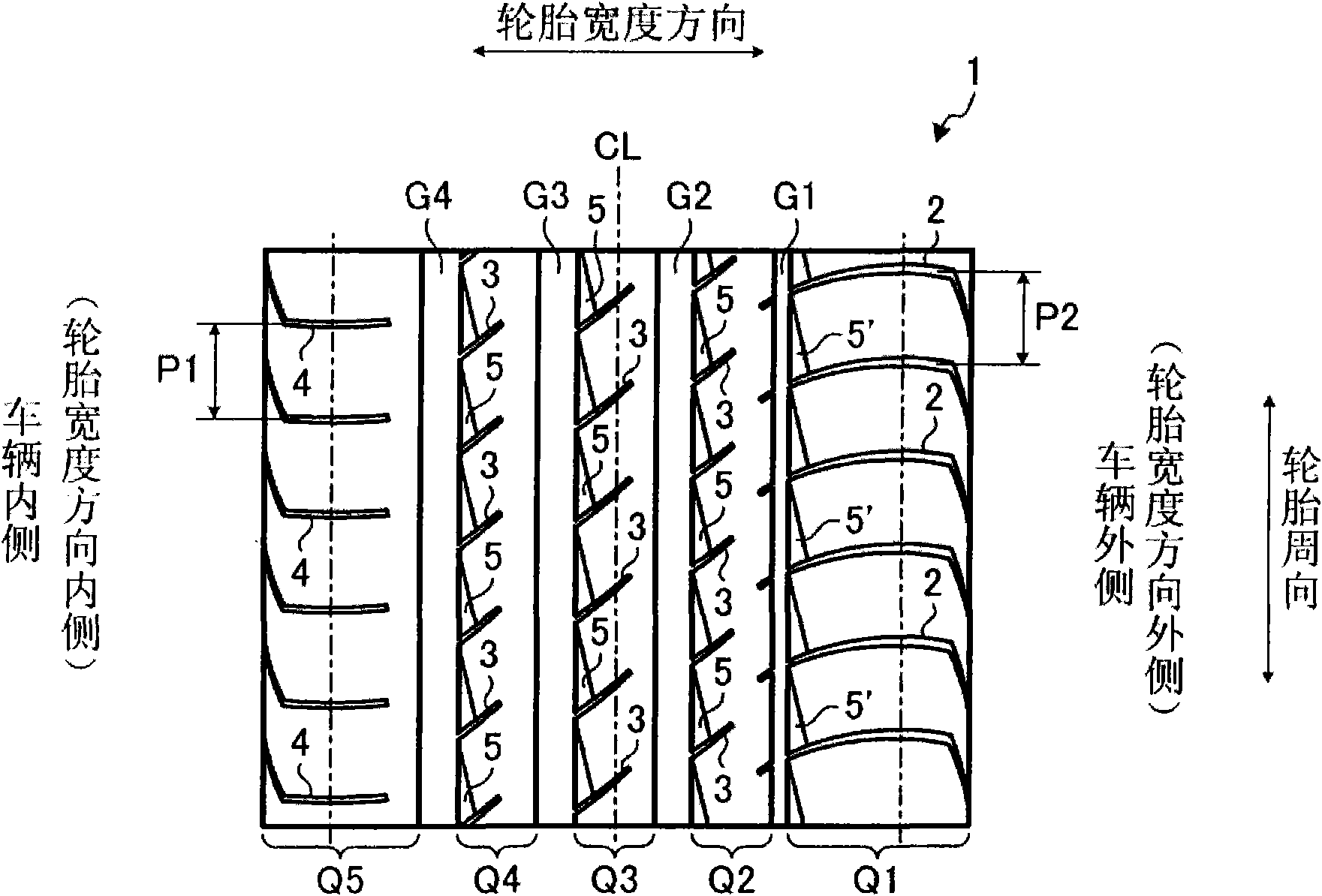

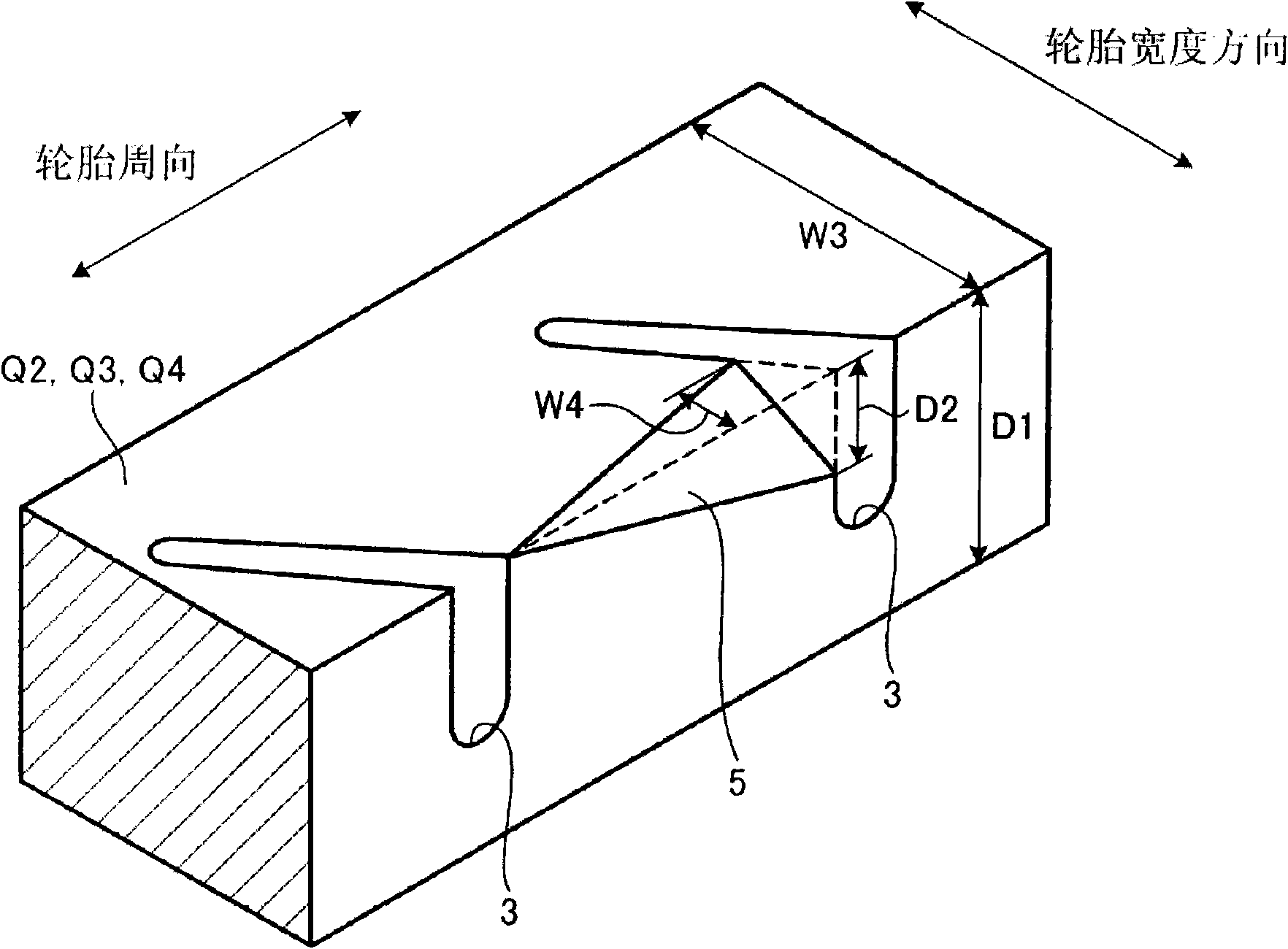

[0067] Take 245 / 40R18 as the tire size, and figure 1 For the basic shape of the tread pattern, tires of the present invention (Examples 1-8) were made respectively, which had figure 1 and figure 2 Shown pattern structure; Comparative tire (comparative example 1), the pattern structure that it has is main groove G1, G2, G3, the groove width of G4 is identical, and as Figure 4 As shown, the inclined groove 3 is connected with the main groove G1, G2, G3 and the horizontal groove 2, 4 is not configured; the comparison tire (comparative example 2) has a pattern structure such as Figure 5 shown in Figure 4 The two shoulders of the tire are configured with rib grooves 2 and 4 connected to the main grooves G1 and G4; the comparative tire (Comparative Example 3) has a pattern structure such as Figure 6 As shown, will figure 1 The lug groove 4 is connected to the main groove G4; and the comparison tire (comparative example 4), such as Figure 7 As shown, its pattern structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com