High-precision vertical type machining center

A vertical machining center, high-precision technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problem of decreased machining accuracy of the machining center, easy chips falling on the guide rail, poor working stability, etc. problems, to achieve the effect of improving machining accuracy, good protection effect, and strong overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

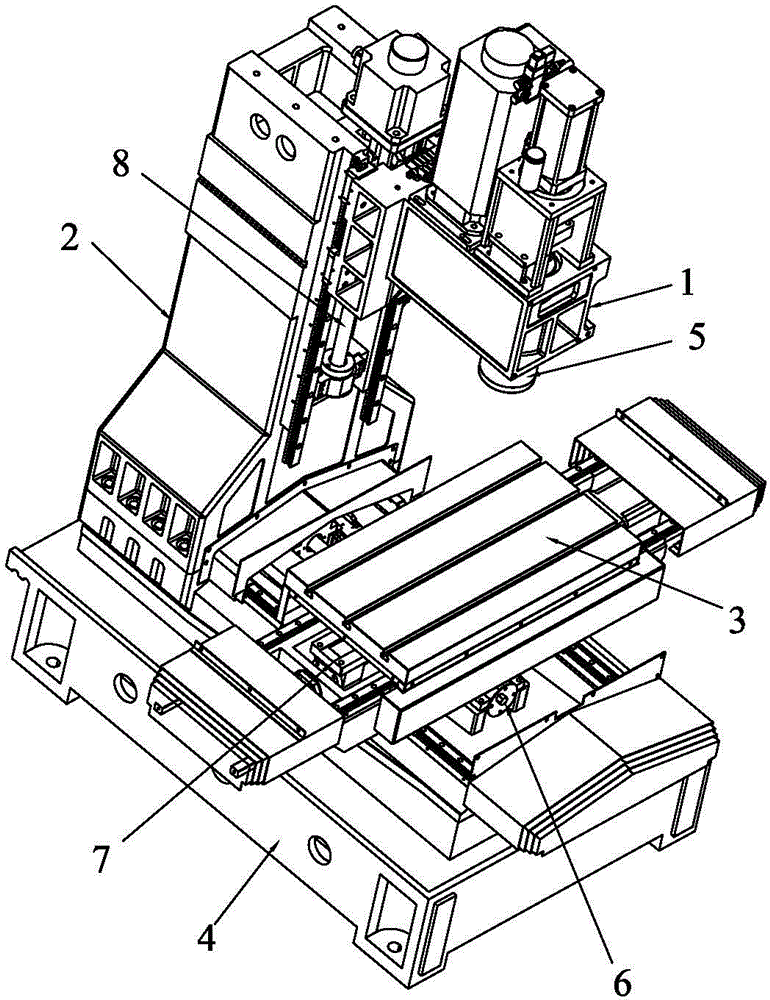

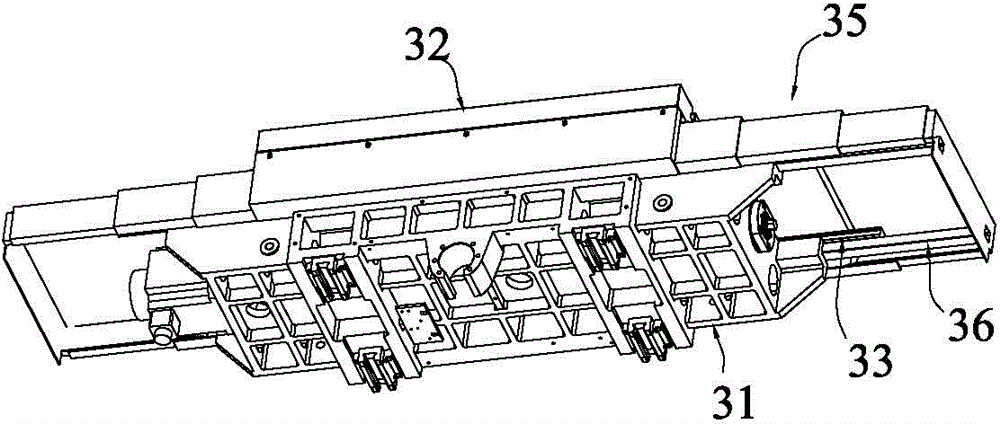

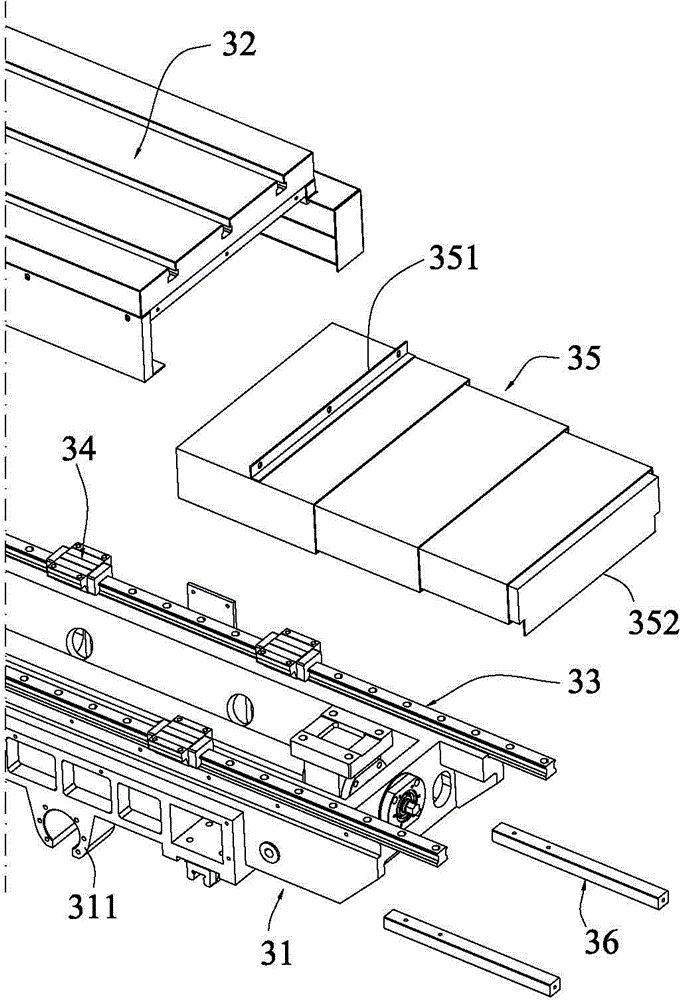

[0025] see Figure 1 to Figure 8 , a kind of high-precision vertical machining center provided by the present embodiment, it comprises base 4, column 2, workbench 3, main shaft box 1, PLC controller and the machining center that is respectively connected with this PLC controller and is controlled by it Main shaft assembly 5 , Y-axis moving mechanism 6 , X-axis moving mechanism 7 and Z-axis moving mechanism 8 , the column 2 is arranged at the rear of the base 4 , and the Y-axis moving mechanism 6 is arranged at the front of the base 4 .

[0026] The spindle housing 1 is arranged on the column 2 through the Z-axis moving mechanism 8. The spindle housing 1 includes a spindle installation horizontal part 11 and a slide seat installation vertical part 12. The slide seat installation vertical part 12 is vertically arranged on the spindle installation horizontal part. 11, the back of the sliding seat installation vertical part 12 is provided with a column slider installation position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com