Pressure pipe radial vibration damping force stilling support

A pressure pipeline and force-reducing technology, which is applied in the field of radial vibration-reducing and force-reducing support for pressure pipelines, can solve problems such as the inability to realize horizontal and radial constraints of pipelines, and achieve the effects of improving anti-corrosion capabilities, good structure and reliability, and maintaining rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

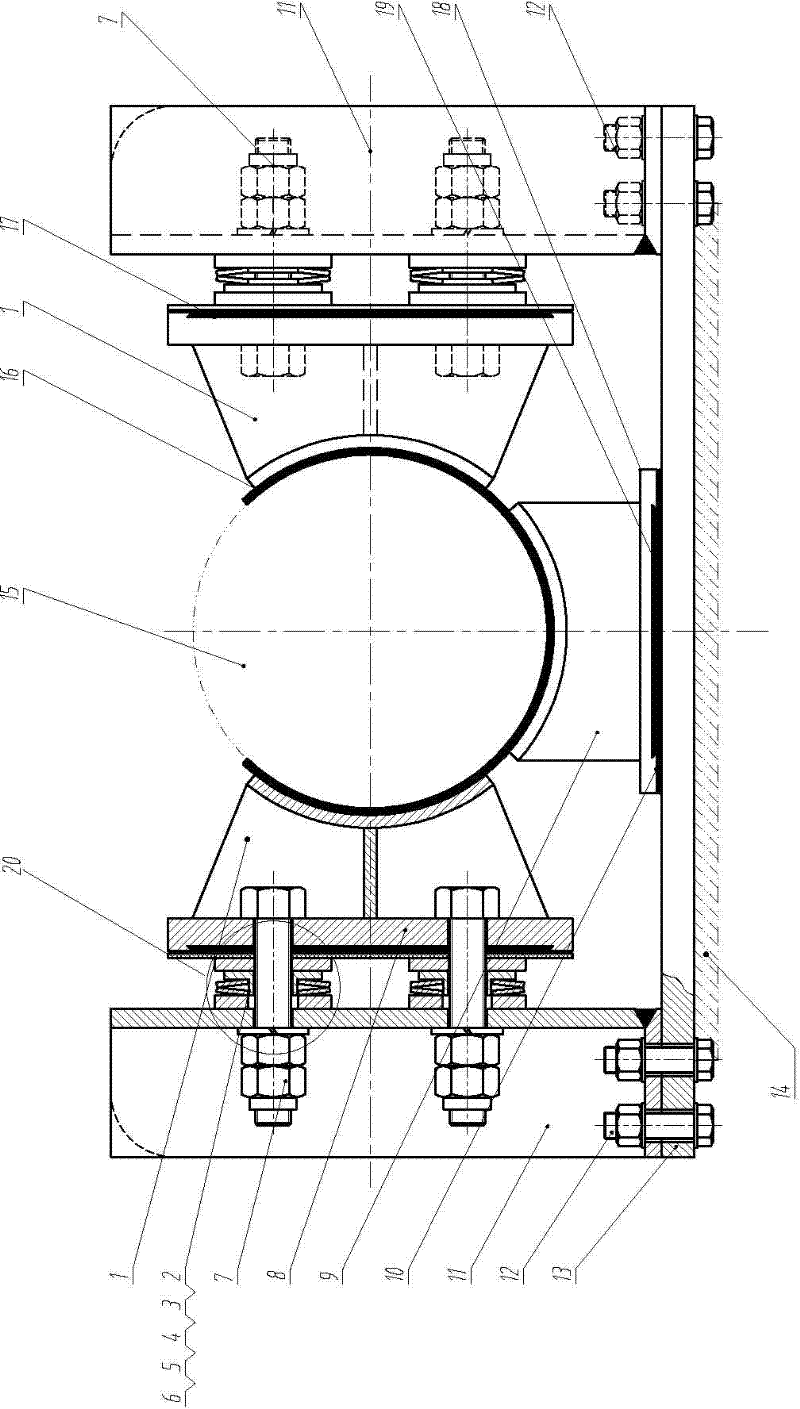

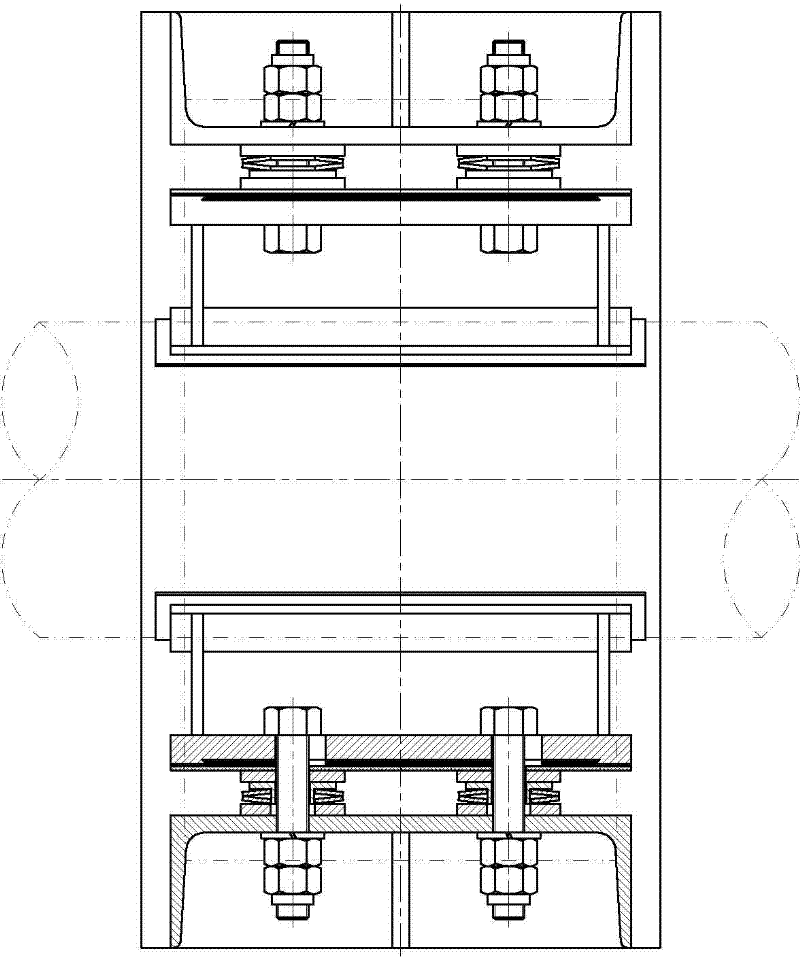

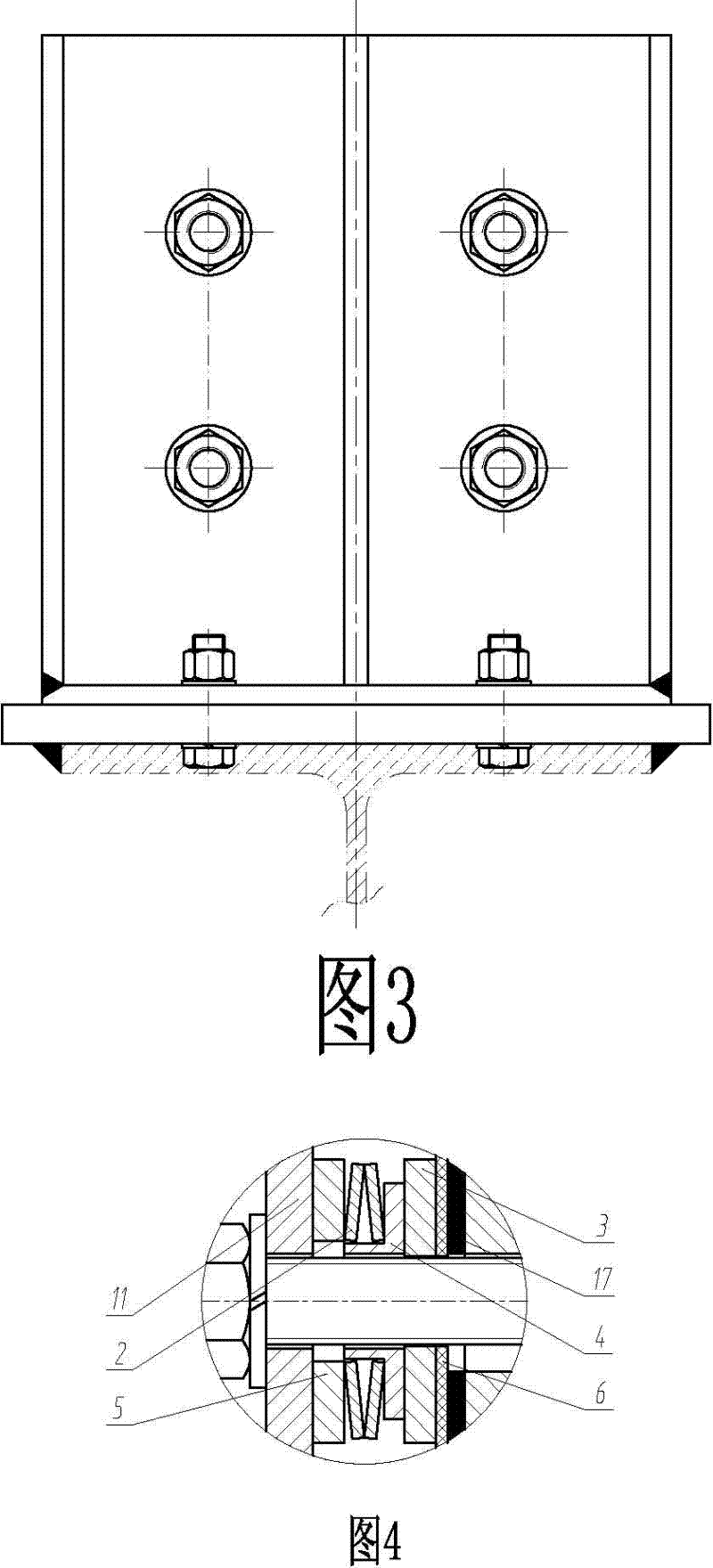

[0016] Such as figure 1 -4 shown.

[0017] A pressure pipe radial vibration damping support, which includes a lower bracket 9 and a lower bottom plate 13, the pressure pipeline 15 is supported on the lower bracket 9, in order to prevent the stilling bracket from causing wear to the pipeline, it can be installed on the pipeline 15 Upper cover is equipped with opening backing plate 16, as figure 1 As shown, the lower support block 9 can be directly supported on the lower base plate 13, or it can be installed on the lower support plate 18 earlier, and the lower support plate 18 is installed on the lower backing plate 19, and the lower backing plate 19 is installed on the lower mirror panel 10, and the lower mirror The panel 10 is then mounted on the lower base plate 13 . Both sides of the lower base plate 13 are symmetrically provided with vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com