Novel integral turning method of blades

A blade and turning technology, which is applied in the field of new integral turning of blades, can solve the problems of insufficient pressing force of the blades, and achieve the effect of ensuring the pressing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

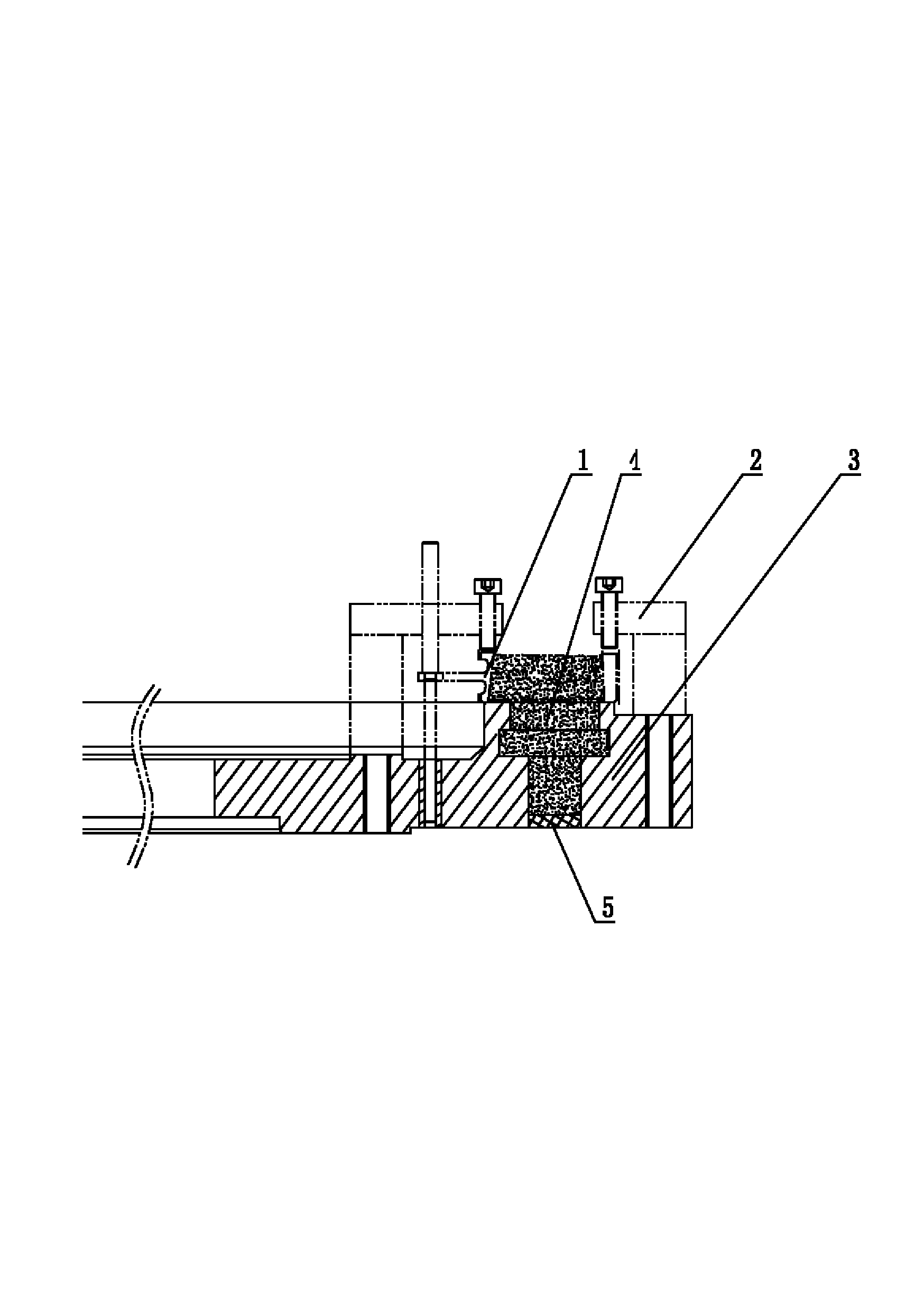

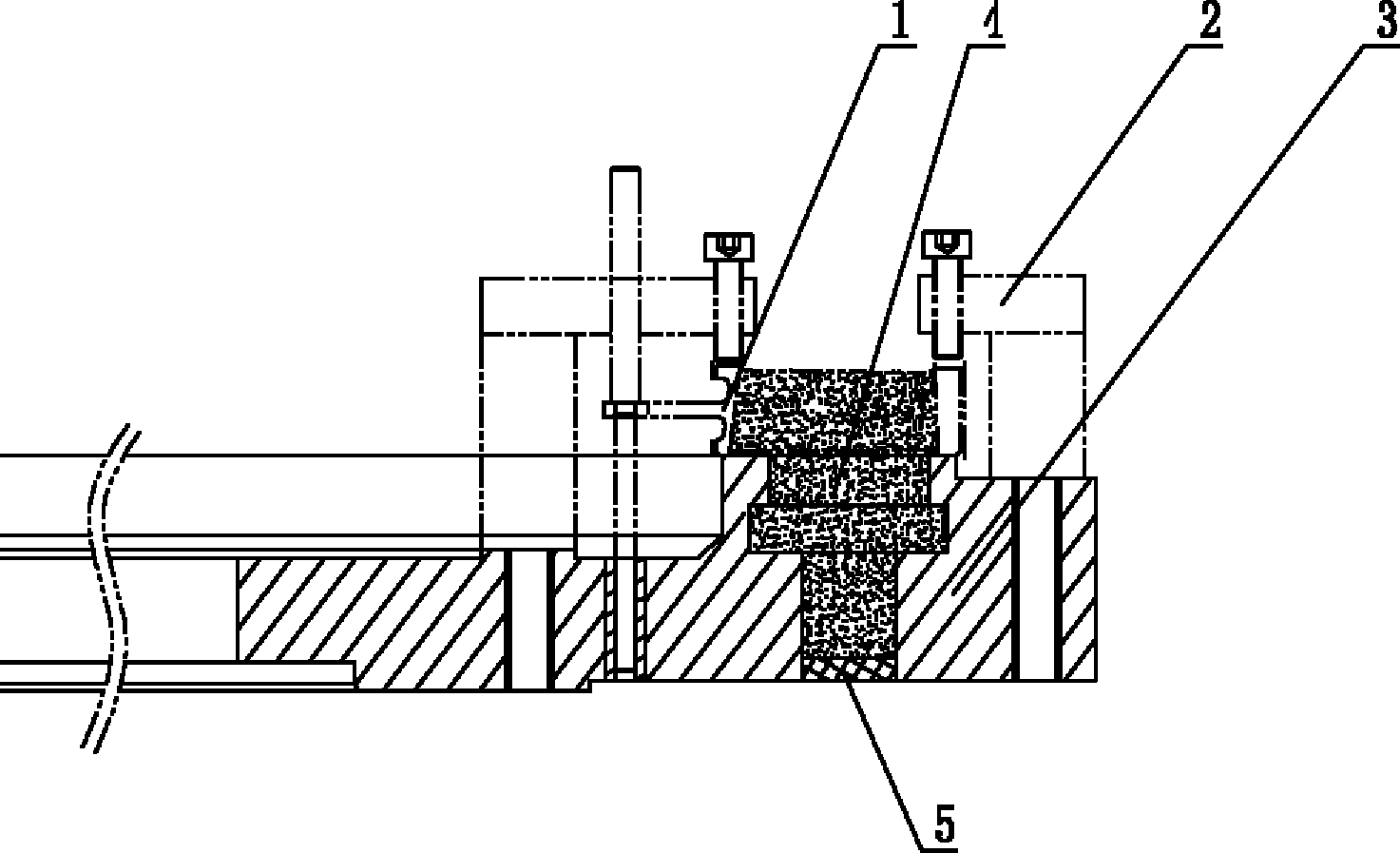

[0008] See figure 1 , the new overall turning method of the blade of the present invention, the blade 1 is positioned in a simulated assembly state and pressed on the turning fixture 3 with the pressure plate 2, and then the low melting point alloy 4 is poured between the blade 1 and the turning fixture 3, and the low melting point After the alloy 4 is cooled and solidified, the pressure plate 2 is removed, and the blade 1 and the turning fixture 3 are firmly bonded by the low melting point alloy 4, so that the blade 1 and the turning fixture 3 form a complete rigid part, and then the blade combination processing is performed. After the blade combination processing is completed, the blade 1 and the turning fixture 3 are put into hot water as a whole, the solid low-melting point alloy 4 is melted by heat, and the blade 1 and the turning fixture 3 are separated. Low melting point alloy 4 is tin-bismuth alloy; the shrinkage ratio of metal tin and metal bismuth in tin-bismuth allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com