Thin-wall sleeve inner hole finish machining clamp and inner hole machining method

A thin-walled sleeve, inner hole technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high production cost, out of tolerance, easy to deform in clamping and processing, and improve production efficiency and efficiency. Economic benefits, lower production costs, and the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

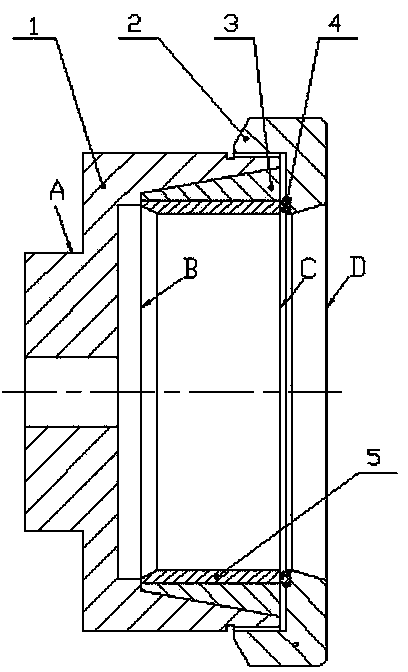

[0013] Example 1 Such as figure 1 Shown: a fixture for finishing the inner hole of a thin-walled sleeve. The positioning seat 1 is composed of a small cylinder A and a large cylinder. The right end of the large cylinder cavity is a conical surface, and the left end of the large cylinder cavity is a round hole. Between the conical surfaces at the right end is a transitional step surface B, and the right end of the large cylinder is provided with a fine-toothed external thread; the external conical surface of the elastic bushing 3 and the right end of the inner cavity of the positioning seat 1 have a taper of 1:10, and the thin-walled sleeve is 5 packs The inner hole of the cylindrical surface of the elastic bushing 3, the left end of the elastic bushing 3 and the thin-walled sleeve 5 withstand the transitional step surface B; The external thread on the right end is matched, and the thin-walled sleeve 5 is compressed by the rubber washer 4 . The side wall of the elastic bushi...

Embodiment 2

[0014] Example 2: A method for finishing the inner hole of a thin-walled sleeve using a jig for finishing the inner hole of the thin-walled sleeve described in Embodiment 1, including:

[0015] ① Fix the small cylinder A of the positioning seat 1 on the three-jaw chuck of the CK63 CNC lathe, and strictly correct the radial and axial runout tolerance of the positioning seat 1 within 0.01mm;

[0016] ② Put the elastic bushing 3 into the inner cavity of the positioning seat 1, and then put it into the thin-walled sleeve 5. The inner hole of the elastic bushing 3 is a cylindrical surface, and maintain a 0.15mm gap with the outer circle of the thin-walled sleeve 5 in the natural state;

[0017] ③ Surface A is concentric with the conical surface, the inner cavity B, C end surfaces and right end surface D are all perpendicular to the axis of surface A, and the outer circle of the right end of positioning seat 1 adopts fine thread, which is also concentric with surface A.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com