Molded product having hollow structure and process for producing same

A molded body and hollow technology, which is applied to hollow objects, chemical instruments and methods, household appliances, etc., can solve the problems of disordered reinforcement fiber orientation, weak resistance to external forces, and weak strength, and achieve high reinforcement effect and light weight Sexuality, the effect of maintaining rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0141] Hereinafter, the present invention will be described in more detail by way of examples.

[0142]

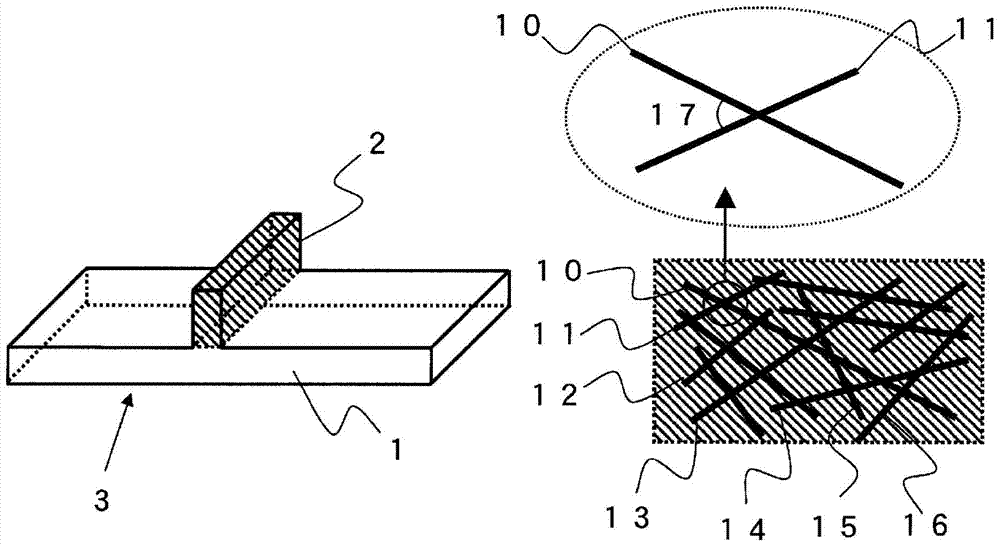

[0143] Cut out from the resulting molded body Figure 22 A portion having a protruding shape as shown in (a), such as Figure 22 As shown in (b), the surface layer portion having a planar shape was wet-polished to a position where the boundary surface between the surface layer portion and the core material portion could be observed, and this was used as a sample for cross-sectional observation. The entire cross-section of the polished sample was photographed at a magnification of 200 times using an ultra-depth color 3D shape measurement microscope VK-9500 (controller part) / VK-9510 (measurement part) (manufactured by KEYENCE Corporation). Measure every 1mm at any position of the boundary surface between the surface layer part and the core material part from the captured image using the analysis application VK-H1A9 2 The number of reinforcing fibers (a1).

[0144]

[...

reference example 1

[0184]

[0185] A continuous bundle of carbon fibers with a total of 12,000 filaments was obtained by spinning and firing a polymer mainly composed of polyacrylonitrile. A sizing agent was applied to the carbon fiber continuous bundle by a dipping method, and dried in heated air at a temperature of 120° C. to obtain a PAN-based carbon fiber bundle. The characteristics of this PAN-based carbon fiber bundle are as follows.

[0186] Single fiber diameter: 7μm

[0187] Weight per unit length: 0.83g / m

[0188] Density: 1.8g / cm 3

[0189] Tensile strength: 4.0GPa

[0190] Tensile modulus of elasticity: 235GPa

[0191] Type of sizing agent: polyoxyethylene oleyl ether

[0192] Sizing agent adhesion amount: 2% by weight

reference example 2

[0193]

[0194] The carbon fibers of Reference Example 1 were cut using a cartridge cutter to obtain chopped carbon fiber bundles having a fiber length of 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com