Preparation method of novel viscosity reducer for thick oil

A heavy oil viscosity reducer, a new type of technology, applied in the field of preparation of new heavy oil viscosity reducer, can solve the problems of poor emulsification viscosity reduction effect, large fixed investment, large processing capacity, etc., to reduce the viscosity of heavy oil and improve the production process Simple, viscosity-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

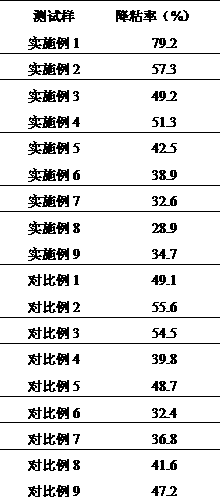

Embodiment 1

[0011] Weigh 100 parts by weight of toluene and place it in the reactor, then add 30 parts of methyl methacrylate and 9 parts of styrene, ultrasonically disperse for 30 minutes, then add 5 parts of maleic anhydride and 3 parts of acrylamide, and heat the reactor to Stir at a constant temperature of 60°C for 1~2h. After the monomer is completely dissolved, fill the reactor with 60% nitrogen and 40% neon for 30 minutes, then raise the temperature to 75~80°C, and slowly add 0.8 parts of benzene peroxide into the reactor. Formyl, heat preservation reaction for 4 hours, then lower the temperature to 65~70°C, add 16 parts of nanometer KH550-CMK-3 composite material, continue heat preservation reaction for 2~3 hours, and discharge to obtain a new type of heavy oil viscosity reducer.

[0012] The preparation method of the above-mentioned nanometer KH550-CMK-3 composite material is as follows:

[0013] Add 75 parts of absolute ethanol and 30 parts of deionized water into the flask, sti...

Embodiment 2

[0015] It is exactly the same as Example 1, except that 30 parts of methyl methacrylate, 12 parts of styrene, 11 parts of maleic anhydride and 4 parts of acrylamide are added.

Embodiment 3

[0017] It is exactly the same as Example 1, except that 30 parts of methyl methacrylate, 15 parts of styrene, 8 parts of maleic anhydride and 5 parts of acrylamide are added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com