Low-shrinkage and low-density modified polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of low shrinkage, low density modified polypropylene composite material and its preparation, can solve the problem of affecting the flow characteristics of polypropylene melt, unfavorable processing of polypropylene composite material, and affecting the comprehensive performance of materials, etc. Problems, to achieve good market prospects and economic benefits, low density, low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

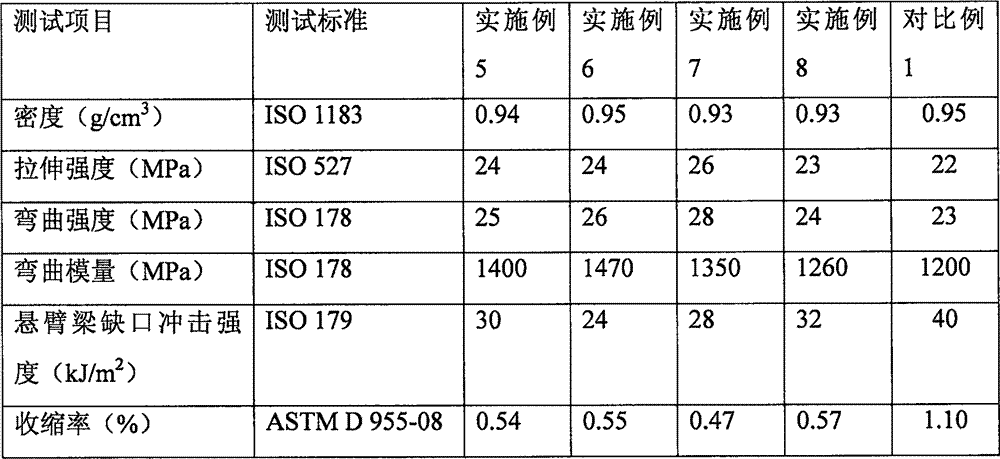

Examples

Embodiment 1

[0029] In this embodiment, the long fiber reinforced resin is prepared as follows:

[0030] First, 45.6kg of polypropylene PP BJ356MO (melt index 100g / 10min), 4kg of compatibilizer maleic anhydride grafted polypropylene (grafting rate 0.8%), 0.2kg of tetrakis [β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.2kg of β, β'-thiodipropionic acid distearate are mixed evenly, then added to the twin-screw extruder for high-temperature melting , the temperature of the extruder is set at 240°C, the mixture is melted and blended by the extruder to obtain a high-temperature melt, and the high-temperature melt is transported to the impregnation mold, and the mold temperature is set at 250°C. After being extruded from the die, 50kg of non-alkali continuous long glass fiber is transported to the impregnation mould. The fiber-reinforced polypropylene strips are introduced into a pelletizer for granulation, and the length of the particles is controlled at 10-30mm, ...

Embodiment 2

[0032] In this embodiment, the long fiber reinforced resin is prepared as follows:

[0033]First, 55.6kg of polypropylene PP SK3920 (melt index 100g / 10min), 4kg of compatibilizer maleic anhydride grafted polypropylene (Shenyang Ketong KT-1, grafting rate 1.0%), 0.2kg of tetra[ β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.2kg of β, after the β'-thiodipropionic acid distearate is mixed uniformly, join the twin-screw High-temperature melting is carried out in the extruder, and the temperature of the extruder is set at 240°C. The mixture is melted and blended by the extruder to obtain a high-temperature melt, and the high-temperature melt is transported to the impregnation mold, and the mold temperature is set at 250°C , after the melt is filled with the mold and extruded from the die, transport 40kg of basalt fiber to the impregnation die, after the basalt fiber is dispersed and impregnated by the high-temperature melt, it is extruded from the die, a...

Embodiment 3

[0035] In this embodiment, the long fiber reinforced resin is prepared as follows:

[0036] First, 55.6kg of nylon 6 (China Baling Petrochemical YH160, relative viscosity 1.64), 4kg of compatibilizer maleic anhydride graft POE (Shenyang Ketong KT-9, grafting rate 0.8%), 0.2kg of four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 0.2kg of β, β'-thiodipropionic acid distearate are mixed evenly, then added to bis High-temperature melting is carried out in the screw extruder, and the temperature of the extruder is set at 240°C. After the mixture is melted and blended by the extruder, a high-temperature melt is obtained. The high-temperature melt is transported to the impregnation mold, and the mold temperature is set at 250°C. ℃, after the melt is filled with the mold and extruded from the die, transport 40kg of carbon fiber to the impregnation die, after the basalt fiber is dispersed and impregnated by the high-temperature melt, it is extruded from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com