Cover tape and electronic component packaging body

A cover tape and antistatic technology, applied in packaging, conductive coatings, coatings, etc., can solve the problems of insufficient antistatic performance of cover tape and the risk of sticking materials, and achieve excellent antistatic performance and low surface resistivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

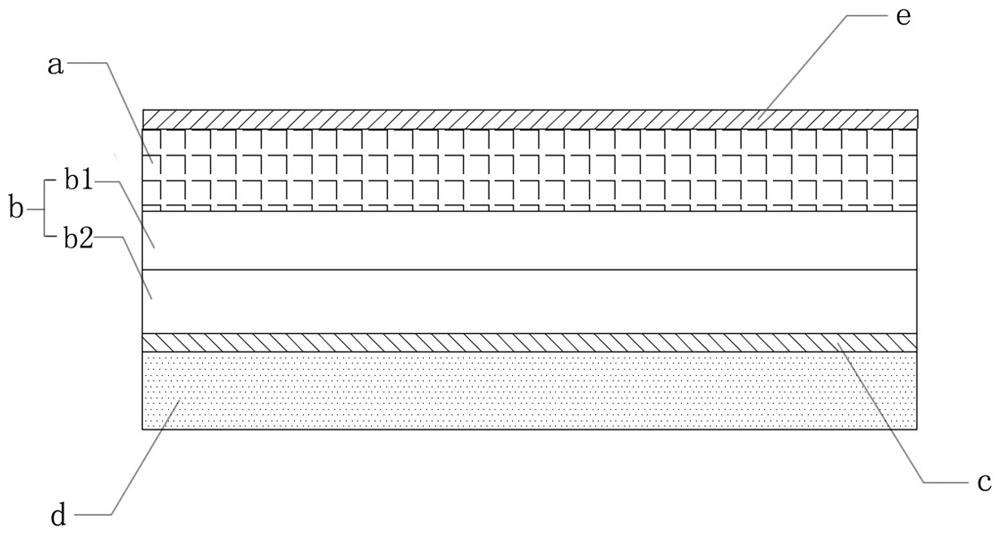

[0040] In this embodiment, the base material layer a can be selected from commonly used materials in the art, so details will not be repeated here.

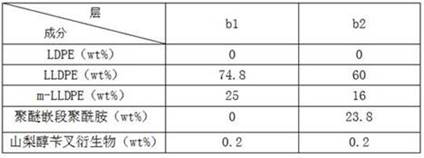

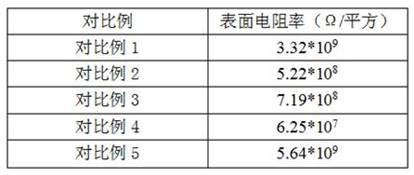

[0041] The middle layer b includes two structural layers b1 and b2, and the selected materials are as follows: LDPE (2426: density 0.925g / cm 3 , MI: 1.9), LLDPE (7042: density 0.918g / cm 3 , MI: 1.8), m-LLDPE (5230G: density 0.916g / cm 3 , MI: 4.0), polyether block polyamide (IRGASTA P), sorbitol benzylidene derivatives (DBS). The composition is as follows:

[0042]

[0043] as attached figure 1 As shown, in this embodiment, an antistatic coating c is coated on the surface of the b2 structural layer, and a second antistatic coating e is coated on the opposite surface of the substrate layer a and the intermediate layer b, specifically: 10wt% thiophenes Conductive polymer (polyethylenedioxythiophene / sodium polystyrene sulfonate composite conductive liquid CAS: 155090-83-8), 90wt% isopropanol / water (50 / 50) solution.

[0044] T...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that the composition of the middle layer b is as follows:

[0049]

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that the composition of the middle layer b is as follows:

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com