Methacrylate-N-naphthyl methacrylamide polymer diesel oil pour point depressant, and preparation method and application thereof

A technology of naphthyl methacrylamide and methacrylate, which is applied in the field of diesel oil pour point depressant, can solve the problems of poor diesel sensitivity, single structure, and general pour point depressant effect, and achieve increased conversion rate, uniform contact, and easy decomposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

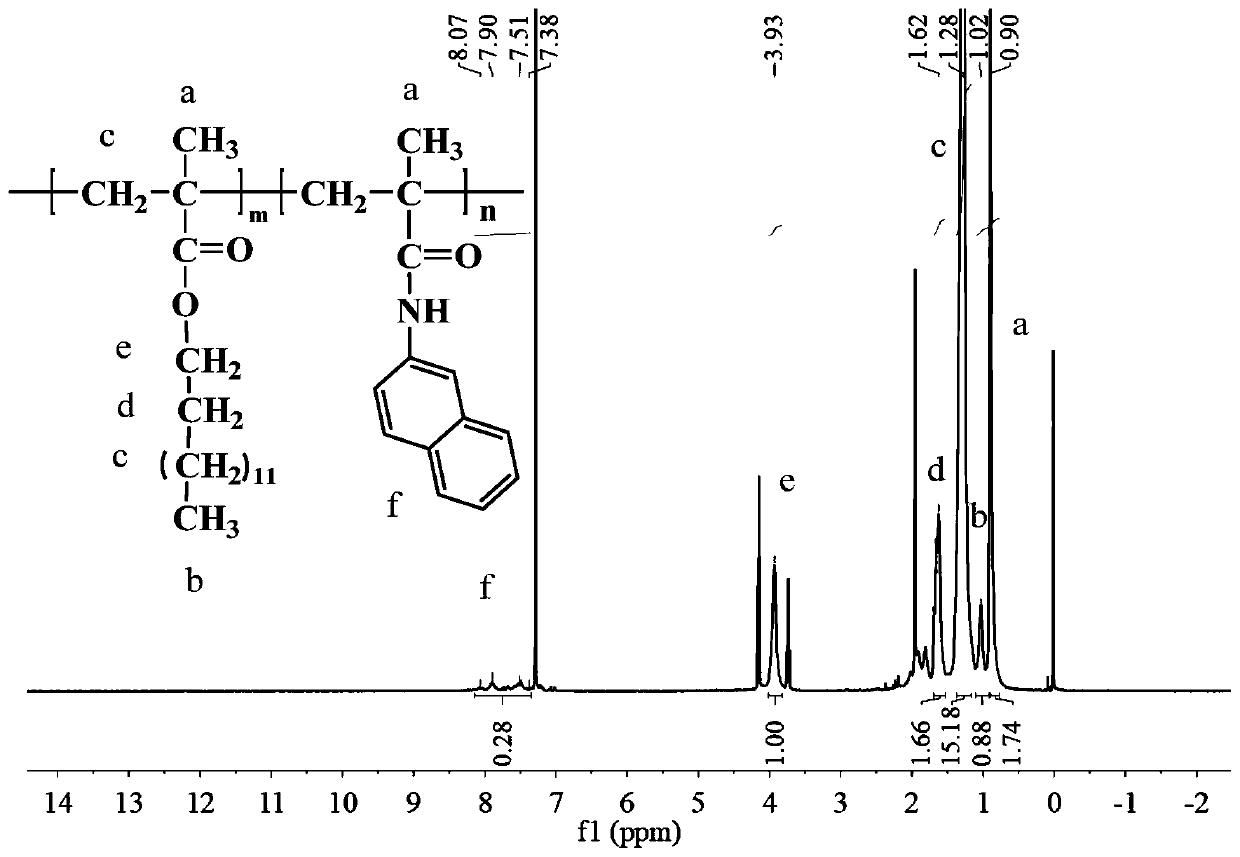

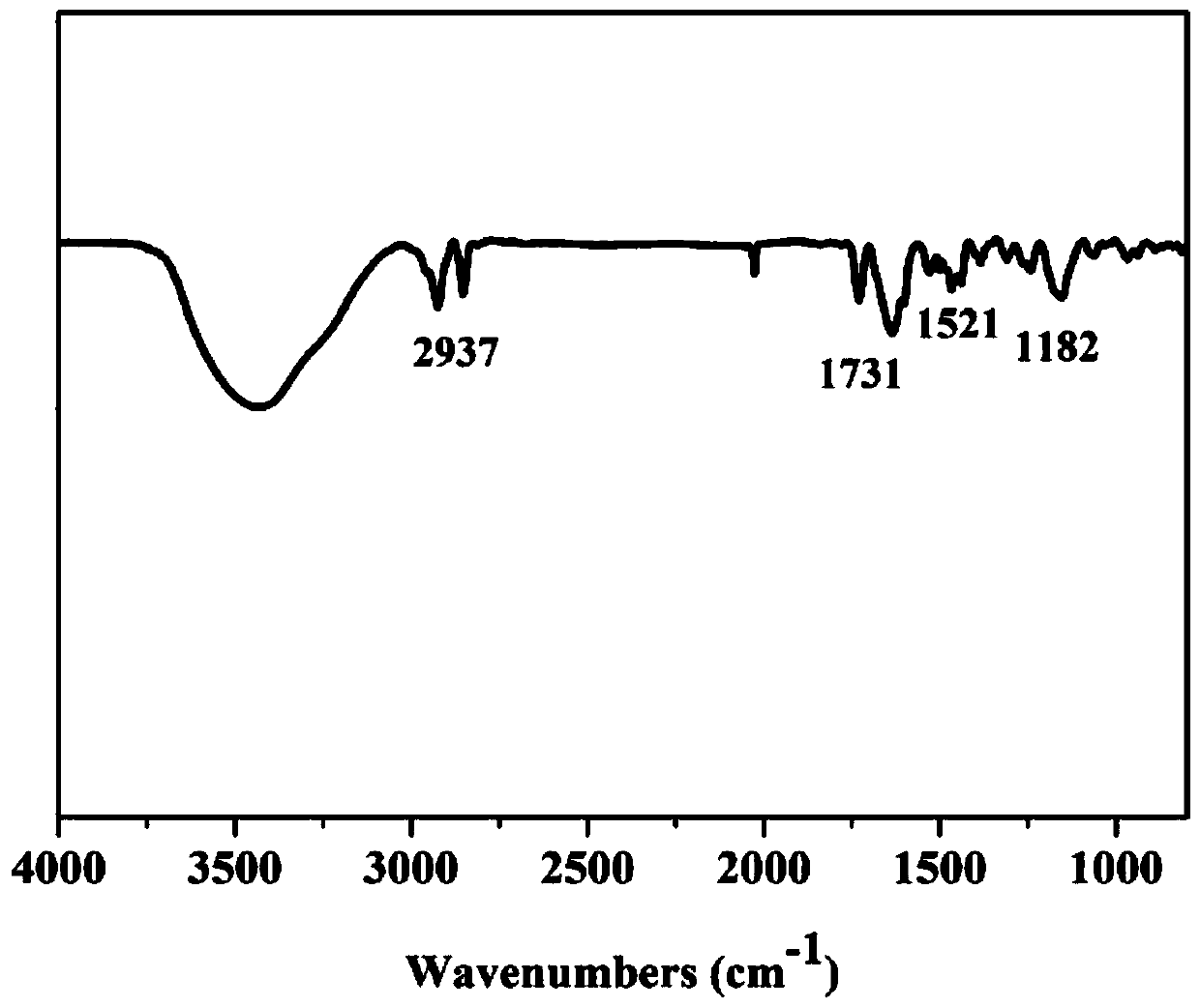

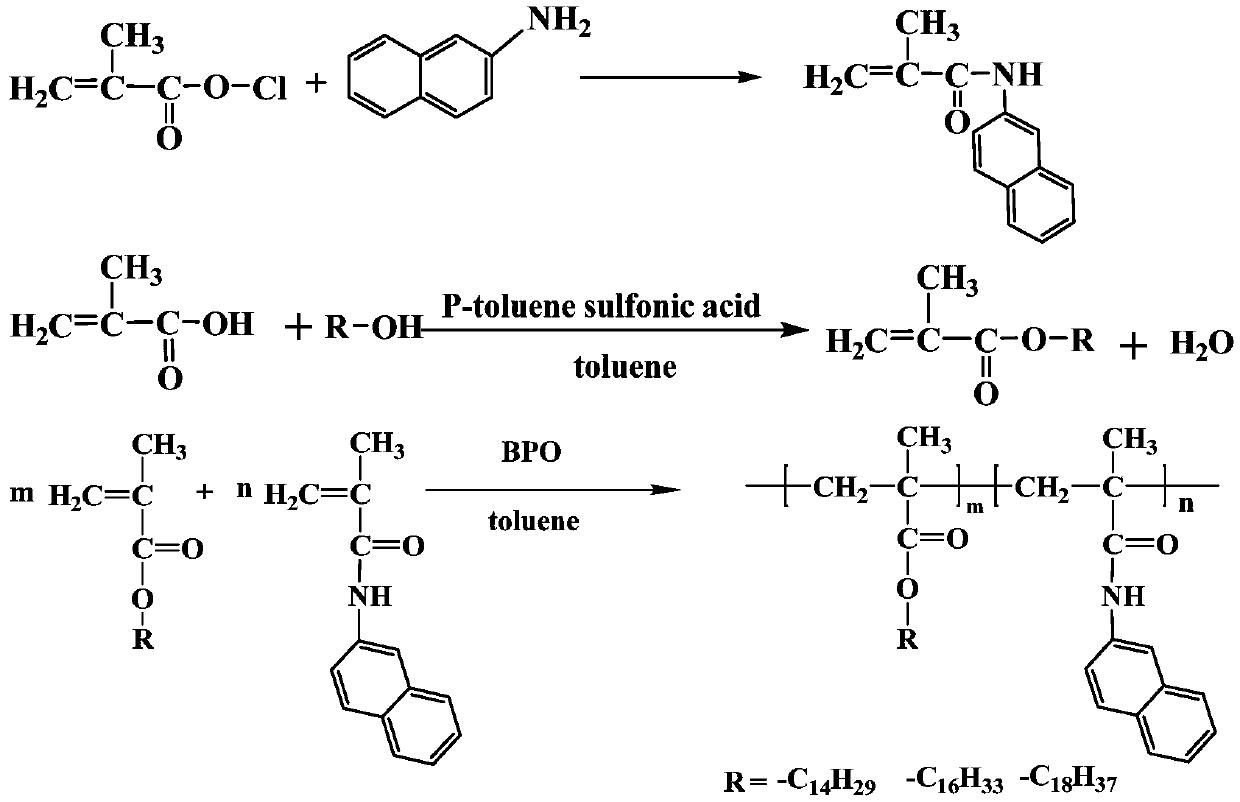

Method used

Image

Examples

Embodiment 1

[0040] (1) Add 10.33g (0.12mol) of methacrylic acid, 21.44g of tetradecyl alcohol (0.1mol), and 0.192g of hydroquinone to a three-necked flask equipped with a condenser, a water separator, a thermometer, and a magnetic stirring device 1. Heat 50ml of toluene to 60°C to completely dissolve myristyl alcohol in toluene, then quickly add 0.254g of catalyst p-toluenesulfonic acid into the three-necked flask, pre-react for 1 hour, then continue to heat up to 115°C, and react for 5-6 hours , when it is observed that the amount of water in the water separator is equivalent to the theoretical value, the system is in a light yellow transparent liquid state, and the reaction is terminated. After the reaction was completed, the obtained reaction solution was distilled under reduced pressure, and then alkali washing and water washing were carried out after removing the solvent. The alkali washing was washed with a 5% NaOH solution to remove p-toluenesulfonic acid and unreacted methyl alcoho...

Embodiment 2

[0046] The difference from Example 1 is that in step (1), 21.44g tetradecyl alcohol (0.1mol), 0.254g catalyst p-toluenesulfonic acid are added instead of adding 24.24g (0.1mol) cetyl alcohol, 0.277g catalyst p-toluenesulfonic acid acid;

[0047] In step (3), add 14.13g (0.05mol) of tetradecyl methacrylate, 0.15g of benzoyl peroxide to change to add 15.53g (0.05mol) of hexadecyl methacrylate, 0.184g of benzoyl peroxide acyl.

Embodiment 3

[0049] The difference from Example 1 is that in step (1), 21.44g tetradecyl alcohol (0.1mol), 0.254g catalyst p-toluenesulfonic acid are added instead of adding 27.05g octadecyl alcohol, 0.299g catalyst p-toluenesulfonic acid;

[0050] In step (2), add 14.13g (0.05mol) of tetradecyl methacrylate, 0.15g of benzoyl peroxide to change to add 16.9g (0.05mol) of octadecyl methacrylate, 0.198g of benzoyl peroxide acyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com