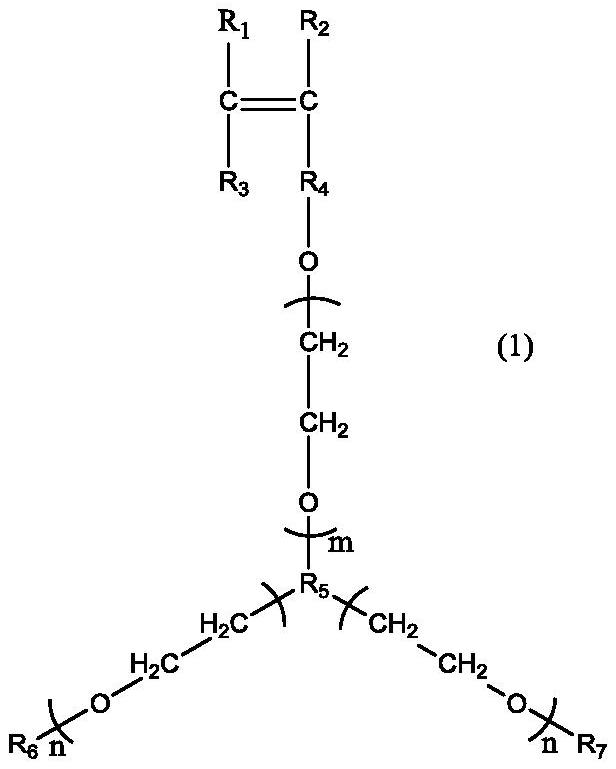

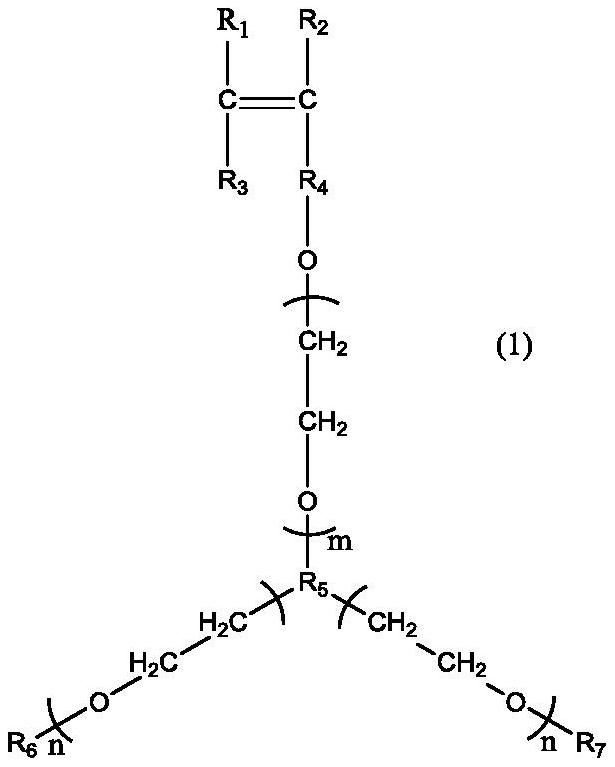

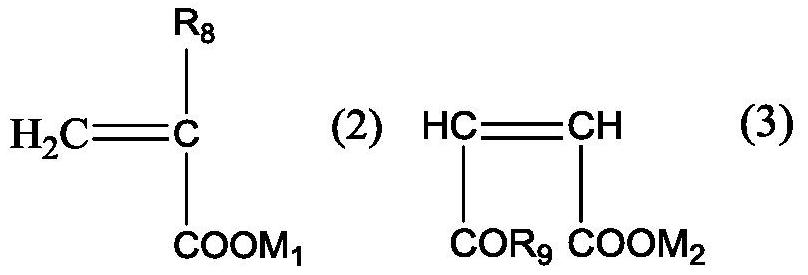

Preparation method of macromonomer with Y-shaped structure

A technology of macromonomers and intermediates, which is applied in the field of preparation of macromonomers with Y-shaped structure, can solve problems such as affecting copolymerization, affecting copolymerization reaction, and unsatisfactory actual performance, and achieves the effect of improving yield and good homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Mix 800 parts by mass of isobutylene polyoxyethylene ether (HPEG) with a molecular weight of 2400 and 176.12 parts by mass of glyceric acid with a molecular weight of 176.12, heat up to 110° C. under a nitrogen atmosphere, and add 14.64 parts by mass of 4-dimethylaminopyridine ( DMAP), the process nitrogen removes the by-product water of the esterification reaction, and reacts for 5h to obtain a mixture of carboxyl-terminated esterification product and unreacted glyceric acid. Weigh 120 parts by mass of the aforementioned mixture, add 50 parts by mass of water to dissolve, then add 50 parts by mass of ethyl bromide, shake to make it evenly mixed, let stand for 30min, keep the ethyl bromide phase after the liquid level is layered, and then add Add 30 parts by mass of water into the ethyl bromide phase, oscillate to mix evenly, let stand for 0.5h, keep the ethyl bromide phase after the liquid level is separated, and then remove the solvent in the ethyl bromide phase by rot...

Embodiment 2

[0037] Mix 800 parts by mass of isobutylene polyoxyethylene ether (HPEG) with a molecular weight of 2400 and 176.12 parts by mass of glyceric acid with a molecular weight of 176.12, heat up to 110° C. under a nitrogen atmosphere, and add 9.76 parts by mass of 4-dimethylaminopyridine ( DMAP), the process nitrogen removes the by-product water of the esterification reaction, and reacts for 5h to obtain a mixture of Y-type intermediate and unreacted glyceric acid. Weigh 120 parts by mass of the aforementioned mixture, add 50 parts by mass of water to dissolve, then add 50 parts by mass of ethyl bromide, shake to make it evenly mixed, let stand for 30min, keep the ethyl bromide phase after the liquid level is layered, and then add Add 30 parts by mass of water into the ethyl bromide phase, oscillate to mix evenly, let stand for 0.5h, keep the ethyl bromide phase after the liquid level is separated, and then remove the solvent in the ethyl bromide phase by rotary evaporation to obtai...

Embodiment 3

[0039] Mix 800 parts by mass of isobutylene polyoxyethylene ether (HPEG) with a molecular weight of 2400 and 176.12 parts by mass of glyceric acid with a molecular weight of 176.12, heat up to 110° C. under a nitrogen atmosphere, and add 19.52 parts by mass of 4-dimethylaminopyridine ( DMAP), the process nitrogen removes the by-product water of the esterification reaction, and reacts for 5h to obtain a mixture of Y-type intermediate and unreacted glyceric acid. Weigh 120 parts by mass of the aforementioned mixture, add 50 parts by mass of water to dissolve, then add 50 parts by mass of ethyl bromide, shake to make it evenly mixed, let stand for 30min, keep the ethyl bromide phase after the liquid level is layered, and then add Add 30 parts by mass of water into the ethyl bromide phase, oscillate to mix evenly, let stand for 0.5h, keep the ethyl bromide phase after the liquid level is separated, and then remove the solvent in the ethyl bromide phase by rotary evaporation to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com