Preparation method of edible color lake based on calcium carbonate

A technology of calcium carbonate and color lake, which is applied in the field of food additives, can solve problems such as hidden safety hazards of aluminum color lake, and achieve the effect of alleviating the worries of aluminum elements, improving safety, and increasing market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

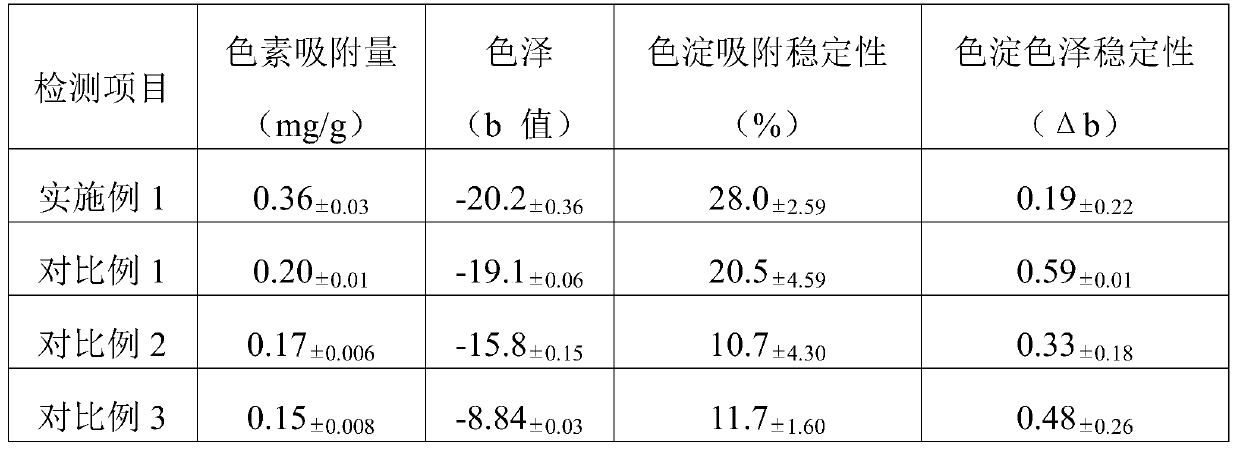

Examples

Embodiment 1

[0030] A preparation method of calcium carbonate-based edible color lake, comprising the following steps:

[0031] S1, 2.0g sodium carbonate is dissolved in 200mL water, obtains sodium carbonate solution;

[0032] S2. Add 50.0 mg of sodium indigo disulfonate to the sodium carbonate solution obtained in step S1, stir well, completely dissolve the pigment, and obtain a mixed solution;

[0033] S3, adding an appropriate amount of hydrochloric acid to the mixed solution obtained in step S2, and adjusting the pH of the mixed solution to pH 10.5;

[0034] S4. Dissolve 2.1g of calcium chloride in 20mL of water and add it to the solution obtained in step S3, stir and sonicate for 2 minutes, the ultrasonic frequency is 40kHz, at this time, calcium carbonate suspended particles are generated, and the pH of the solution is about 8.2, using a centrifuge Quickly centrifuge and collect the calcium carbonate precipitate with the pigment adsorbed;

[0035] S5. Dry the pigment-adsorbed calci...

Embodiment 2

[0037] A preparation method of calcium carbonate-based edible color lake, comprising the following steps:

[0038] S1, 2.0g sodium carbonate is dissolved in 200mL water, obtains sodium carbonate solution;

[0039] S2. Add 50 mg of erythrosine to the sodium carbonate solution obtained in step S1, stir well, completely dissolve the pigment, and obtain a mixed solution;

[0040] S3, adding an appropriate amount of hydrochloric acid to the mixed solution obtained in step S2, and adjusting the pH of the mixed solution to pH 10.5;

[0041] S4. Dissolve 2.1g of calcium chloride in 20mL of water and add it to the solution obtained in step S3, stir and sonicate for 2 minutes, the ultrasonic frequency is 40kHz, at this time, calcium carbonate suspended particles are generated, and the pH of the solution is about 7.8. Use a centrifuge Quickly centrifuge and collect the calcium carbonate precipitate with the pigment adsorbed;

[0042] S5. Dry the pigment-adsorbed calcium carbonate preci...

Embodiment 3

[0044] A preparation method of calcium carbonate-based edible color lake, comprising the following steps:

[0045] S1, 2.0g sodium carbonate is dissolved in 200mL water, obtains sodium carbonate solution;

[0046] S2. Add 50 mg of Brilliant Blue to the sodium carbonate solution obtained in step S1, stir well to completely dissolve the pigment, and obtain a mixed solution;

[0047] S3, adding an appropriate amount of hydrochloric acid to the mixed solution obtained in step S2, and adjusting the pH of the mixed solution to pH 10;

[0048] S4. Dissolve 2.1g of calcium chloride in 20mL of water and add it to the solution obtained in step S3. Stir and sonicate for 5min at a frequency of 60kHz. At this time, suspended particles of calcium carbonate are generated, and the pH of the solution is about 6.8. Use a centrifuge Quickly centrifuge and collect the calcium carbonate precipitate with the pigment adsorbed;

[0049] S5. Dry the pigment-adsorbed calcium carbonate precipitate obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com