Heavy oil viscosity reducer as well as preparation method and application thereof

A heavy oil viscosity reducer and solvent technology, applied in the field of heavy oil viscosity reducer, can solve the problems of difficulty in dissolution, low viscosity reduction rate, failure to meet the requirements of mining and transportation, etc., and achieves improved grafting rate, easy and stable dispersion , the effect of increasing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

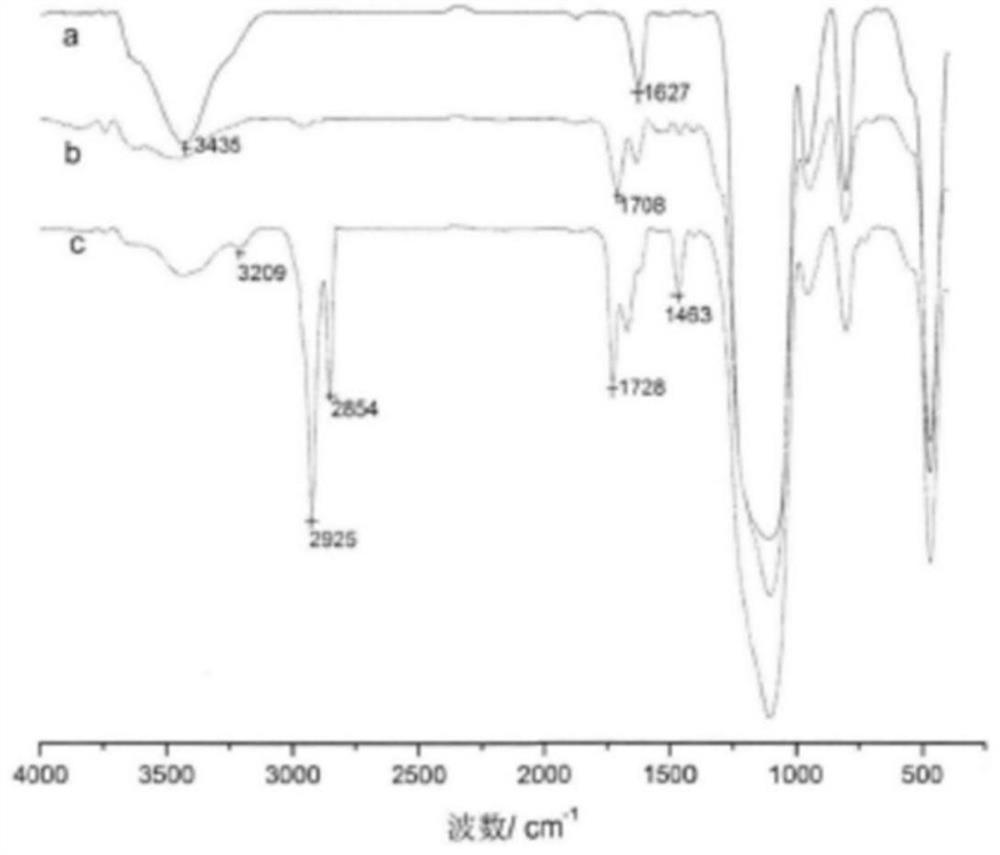

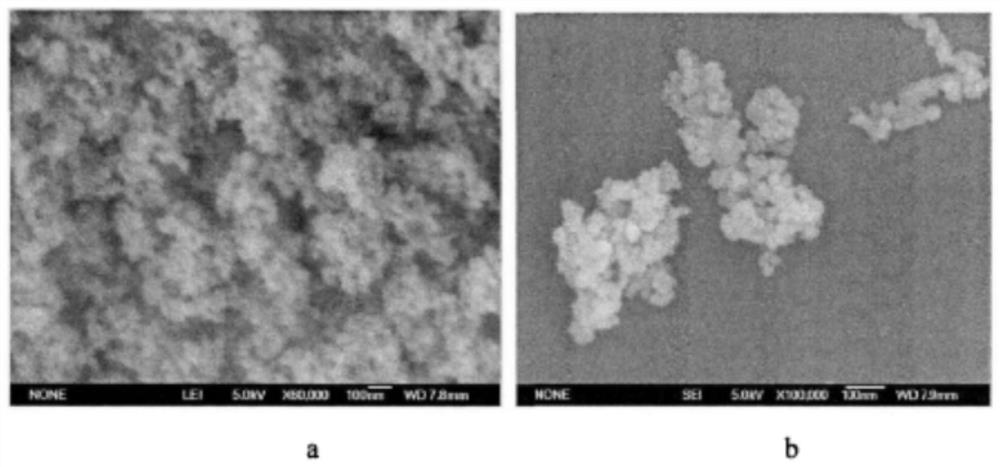

[0075] The preparation of embodiment 1 sample 1

[0076] Step (1) Add 50ml of absolute ethanol, 1ml of acetic acid, 1ml of distilled water, and 1ml of KH570 (γ-methacryloxypropyltrimethoxysilane) to a 100ml three-necked flask in sequence;

[0077] Step (2) The mixture in step (1) is mechanically stirred at room temperature, hydrolyzed for 2 hours, and the stirring speed is 200r / min;

[0078] Step (3) adds 2.5g nanometer SiO in step (2) 2 , heated to 50°C, and reacted for 3h under vigorous stirring.

[0079] Step (4) The reaction product is centrifuged (rotating speed 4000r / min), and washed several times with absolute ethanol;

[0080] Step (5) Vacuum drying at 30°C for 10 hours to obtain the pre-modified product nano KH570 / SiO 2 ;

[0081] Step (6) Disperse the pre-modified product in step (5) evenly in absolute ethanol, add a certain amount of stearyl methacrylate (SMA) and acrylamide (AM), mix and dissolve, and heat up to 80°C ;

[0082] Step (7) After passing nitrogen...

Embodiment 2

[0085] The preparation of embodiment 2 sample 2

[0086] Step (1) Add 50ml of absolute ethanol, 1ml of acetic acid, 1ml of distilled water, and 1ml of KH570 (γ-methacryloxypropyltrimethoxysilane) to a 100ml three-necked flask in sequence;

[0087] Step (2) The mixture in step (1) is mechanically stirred at room temperature, hydrolyzed for 2 hours, and the stirring speed is 500r / min;

[0088] Step (3) adds 2.5g nanometer SiO in step (2) 2 , heated to 50°C, and reacted for 3h under vigorous stirring.

[0089] Step (4) The reaction product is centrifuged (rotating speed 4000r / min), and washed several times with absolute ethanol;

[0090] Step (5) Vacuum drying at 30°C for 10 hours to obtain the pre-modified product nano KH570 / SiO 2 ;

[0091] Step (6) Disperse the pre-modified product in step (5) evenly in absolute ethanol, add a certain amount of stearyl methacrylate (SMA) and acrylamide (AM), mix and dissolve, and heat up to 80°C ;

[0092] Step (7) After passing nitrogen...

Embodiment 3

[0095] The preparation of embodiment 3 sample 3

[0096] Other operation is with embodiment 1, difference is that the silane coupling agent that adopts in the step (1) is vinyltriethoxysilane; Obtain final product nanometer PSMA-AM / SiO 2 Viscosity reducer for composite material, denoted as sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com