Planar ring and blister diaphragm for improved diaphragm-type pressure sensor

a diaphragm and diaphragm technology, applied in the field of pressure sensors, can solve the problems of high cost, added expense, and high price of the detector b>20/b>, and achieve the effect of increasing the signal strength, increasing the pressure sensitivity, and not adding cost and complexity to the electronic detector circuitry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following description is provided to enable any person skilled in the art to make and use the invention and sets forth the best modes contemplated by the inventor of carrying out his invention, Various modifications, however, will remain readily apparent to those skilled in the art, since the generic principles of the present invention have been defined herein specifically to provide an Improved Bellow-Type Pressure Sensing Apparatus.

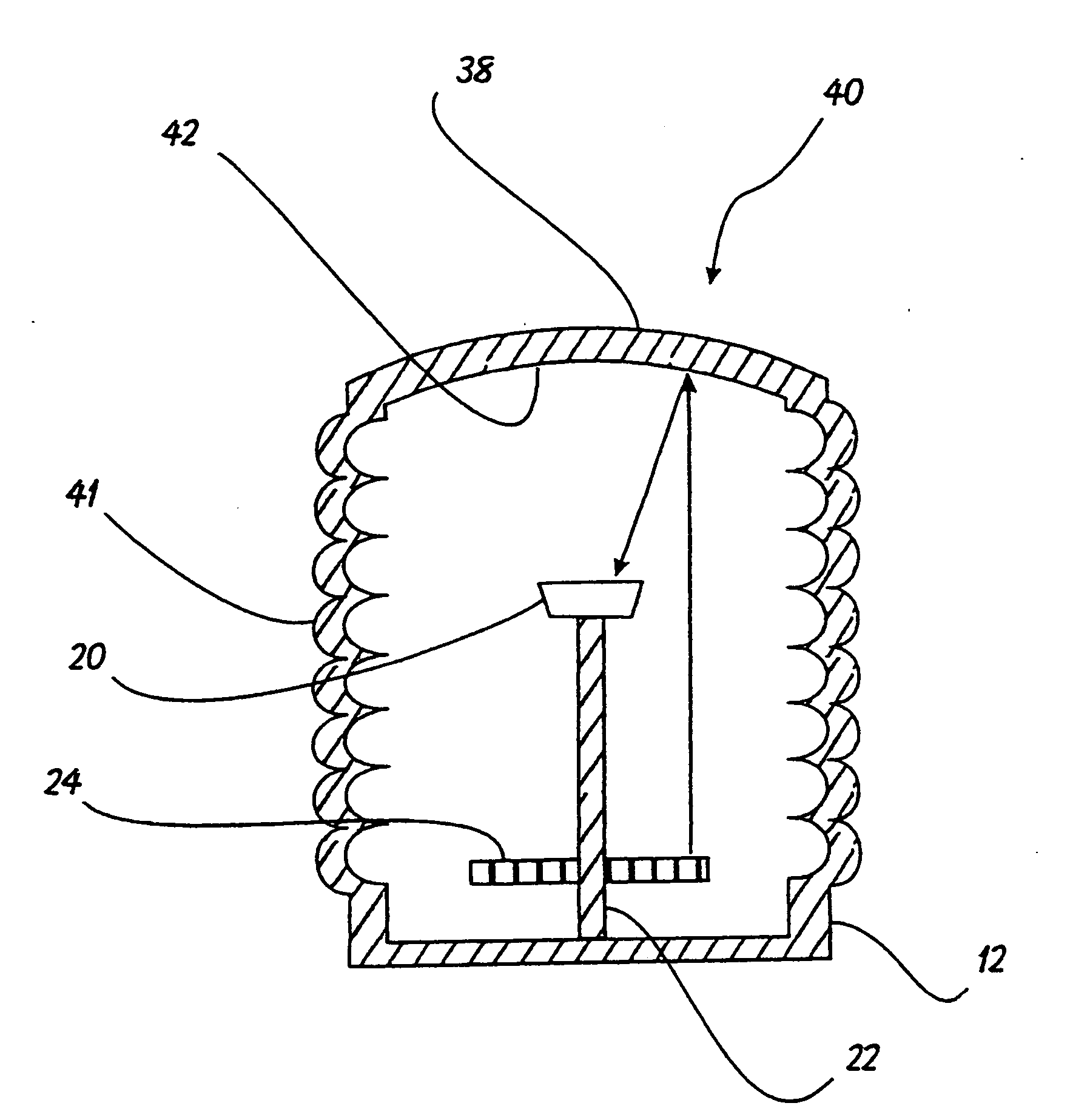

[0034] The present invention can best be understood by initial consideration of FIG. 5. If we now turn to FIG. 5 we can examine the improved bellow-type pressure sensor 40 of the present invention.

[0035]FIG. 5 is a preferred embodiment of the improved bellow type pressure sensor 40 of the present invention. As can be seen (and just as with the prior art sensor), the sensor 40 comprises a stem 12 and a detector 20. Unlike the prior unit, however, this bellow assembly 41 comprises a curved head 38, which further forms a curved reflector 42 (k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| outer dimensions | aaaaa | aaaaa |

| external forces | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com