Corrosion-resistant cable material and preparation method thereof

A cable material and corrosion-resistant technology, applied in the field of corrosion-resistant cable material and its preparation, can solve the problems of affecting the insulation performance of the sheath material, poor thermal stability, safety hazards, etc., and achieve excellent high-temperature chemical stability, excellent toughening and reinforcement. effect, the effect of enhancing the resistance to mechanical shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

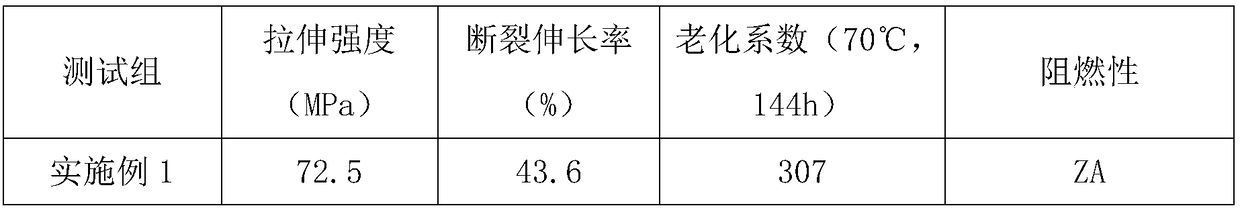

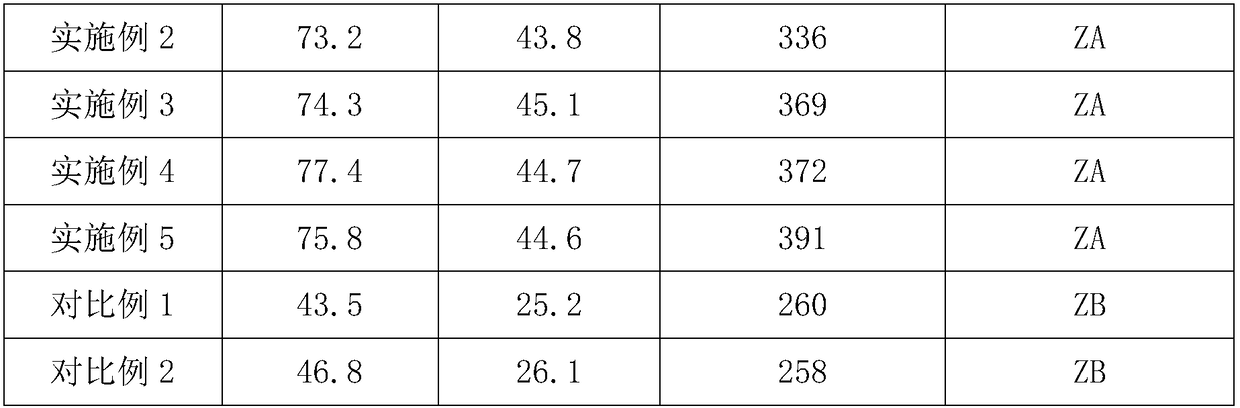

Examples

Embodiment 1

[0031] A corrosion-resistant cable material, comprising the following raw materials in parts by weight:

[0032] 60 parts of polypropylene, 20 parts of EPDM rubber, 15 parts of glass fiber, 8 parts of ultrafine diatomite, 10 parts of modified basic magnesium sulfate whiskers, 3 parts of white carbon black, 3 parts of zirconia, poly 1 part of tetrafluoroethylene, 1.5 parts of neodymium oxide, 2 parts of tetrabutyl titanate, 1.5 parts of melamine, 0.8 parts of β nucleating agent, 2.5 parts of plasticizer, 0.4 parts of crosslinking agent, 1.5 parts of antioxidant and lubricant 1.5 servings.

[0033] The preparation method of modified basic magnesium sulfate whisker is:

[0034] Add basic magnesium sulfate whiskers into deionized water, mix evenly, add a certain amount of emulsifier sodium lauryl sulfate and initiator ammonium persulfate, after heating up to 80 degrees Celsius, slowly drop methyl methacrylate to carry out Emulsion methyl ester polymerization, standing for 30 min...

Embodiment 2

[0047] A corrosion-resistant cable material, comprising the following raw materials in parts by weight:

[0048] 70 parts of polypropylene, 30 parts of EPDM rubber, 22 parts of glass fiber, 15 parts of ultrafine diatomite, 16 parts of modified basic magnesium sulfate whiskers, 7 parts of white carbon black, 7 parts of zirconia, poly 3 parts of tetrafluoroethylene, 3.2 parts of neodymium oxide, 4 parts of tetrabutyl titanate, 2.5 parts of melamine, 1.8 parts of β nucleating agent, 4 parts of plasticizer, 0.8 part of crosslinking agent, 2.5 parts of antioxidant and lubricant 2.5 servings.

[0049] The preparation method of modified basic magnesium sulfate whisker is:

[0050] Add basic magnesium sulfate whiskers into deionized water, mix evenly, add a certain amount of emulsifier sodium lauryl sulfate and initiator ammonium persulfate, after heating up to 80 degrees Celsius, slowly drop methyl methacrylate to carry out Emulsion methyl ester polymerization, standing for 40 minu...

Embodiment 3

[0063] A corrosion-resistant cable material, comprising the following raw materials in parts by weight:

[0064] 62 parts of polypropylene, 22 parts of EPDM rubber, 17 parts of glass fiber, 10 parts of ultrafine diatomite, 12 parts of modified basic magnesium sulfate whiskers, 4 parts of white carbon black, 4 parts of zirconia, poly 1.5 parts of tetrafluoroethylene, 2 parts of neodymium oxide, 2.5 parts of tetrabutyl titanate, 1.8 parts of melamine, 1.2 parts of β-nucleating agent, 3 parts of plasticizer, 0.5 parts of crosslinking agent, 1.8 parts of antioxidant and lubricant 1.8 servings.

[0065] The preparation method of modified basic magnesium sulfate whisker is:

[0066] Add basic magnesium sulfate whiskers into deionized water, mix evenly, add a certain amount of emulsifier sodium lauryl sulfate and initiator ammonium persulfate, after heating up to 80 degrees Celsius, slowly drop methyl methacrylate to carry out Emulsion methyl ester polymerization, standing for 32 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com