High-elasticity transparent mirror frame material

A highly elastic and transparent technology, applied in the field of modified polyamide, can solve the problems of poor yellowing resistance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

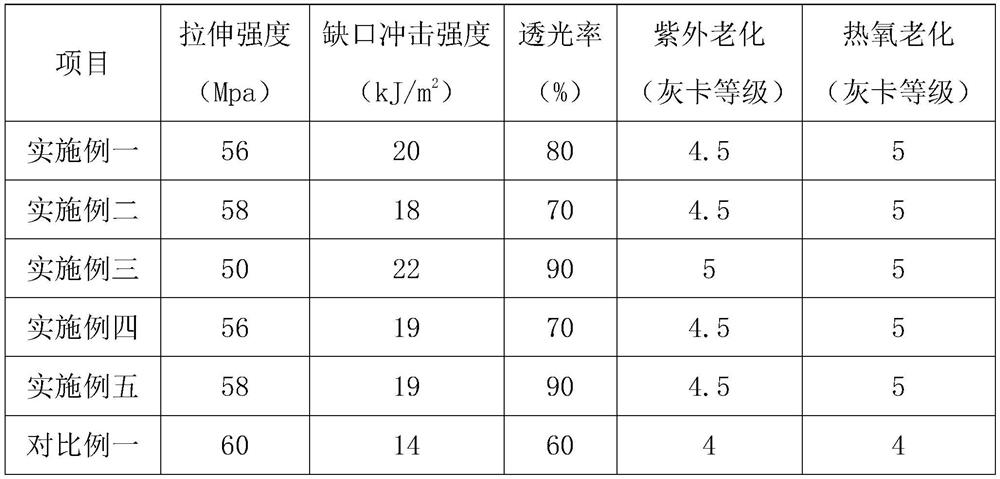

Examples

Embodiment 1

[0021] A kind of highly elastic transparent mirror frame material is made of the following raw materials by weight: 90wt% PA12, 10wt% polyethylene, 0.5wt% antioxidant, 0.3wt% antireflection agent and 1.5wt% white oil, antireflection agent is A mixture of 10 wt% 4-tert-butylbenzoic acid, 10 wt% sodium benzoate, 10 wt% organic phosphate, 10 wt% adipic acid, 10 wt% diphenylacetic acid and 50 wt% sodium succinate, antioxidant 20wt% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 20wt% tris[2,4-di-tert-butylphenyl] phosphite and 60 wt% mixture of N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, model TR90 for PA12, model 7042 for polyethylene , White oil is a mixture of liquid hydrocarbons, the main component of which is a mixture of C16-C31 normal isoparaffins.

[0022] Its preparation process is as follows:

[0023] S1: Add PA12 and polyethylene to a high-speed mixer, premix and stir at a low speed of 100r / min at 1...

Embodiment 2

[0032] A high-elasticity transparent frame material, made of the following raw materials by weight: 90wt% PA12, 5wt% polyethylene, 0.5wt% antioxidant, 0.3wt% antireflection agent and 1.5wt% white oil, antireflection agent is A mixture of 10 wt% 4-tert-butylbenzoic acid, 10 wt% sodium benzoate, 10 wt% organic phosphate, 10 wt% adipic acid, 10 wt% diphenylacetic acid and 50 wt% sodium succinate, antioxidant 20wt% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 20wt% tris[2,4-di-tert-butylphenyl] phosphite and 60 wt% mixture of N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, model TR90 for PA12, model 7042 for polyethylene , White oil is a mixture of liquid hydrocarbons, the main component of which is a mixture of C16-C31 normal isoparaffins.

[0033] Its preparation process is as follows:

[0034] S1: Add PA12 and polyethylene to a high-speed mixer, premix and stir at a low speed of 100r / min at 110°C for 25 minut...

Embodiment 3

[0043]A high-elasticity transparent frame material, made of the following raw materials by weight: 90wt% PA12, 20wt% polyethylene, 0.5wt% antioxidant, 0.3wt% antireflection agent and 1.5wt% white oil, antireflection agent is A mixture of 10 wt% 4-tert-butylbenzoic acid, 10 wt% sodium benzoate, 10 wt% organic phosphate, 10 wt% adipic acid, 10 wt% diphenylacetic acid and 50 wt% sodium succinate, antioxidant 20wt% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 20wt% tris[2,4-di-tert-butylphenyl] phosphite and 60 wt% mixture of N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, model TR90 for PA12, model 7042 for polyethylene , White oil is a mixture of liquid hydrocarbons, the main component of which is a mixture of C16-C31 normal isoparaffins.

[0044] Its preparation process is as follows:

[0045] S1: Add PA12 and polyethylene to a high-speed mixer, premix and stir at a low speed of 100r / min at 110°C for 25 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com