A kind of preparation method of multistage pore Y molecular sieve

A molecular sieve and channel technology, applied in the field of molecular sieve synthesis, can solve the problems of reducing the crystallinity and silicon-aluminum ratio of molecular sieves, destroying the crystal structure of molecular sieves, etc., and achieve the effects of low acid density, high specific surface area, and excellent non-polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 50g NaY molecular sieve (silicon-aluminum ratio 5.6), add 250g 1mol / L NaOH solution, place in a 90°C water bath and stir rapidly for 1 h, take out the sample, and wash it with deionized water until PH<8.

[0032] Get the dried sample that 10g has processed and place in the quartz tube reactor, in the N of 40ml / min 2 Under the purging speed, the temperature was raised to 600°C at a rate of 3°C / min and kept for 120min. Then set the temperature to 450°C, switch N when the temperature drops to 450°C 2 SiCl 4 saturated N 2 (i.e. N2 slowly bubbled through SiCl 4 solution), where N 2 The flow rate is 40ml / min and maintained for 120min. Then switch the gas to pure N 2 , after purging for 120min, it naturally cooled to room temperature, and the sample was taken out. The removed sample was washed with deionized water, dried, and the above SiCl 4 Dealumination and silicon supplementation step.

[0033] Prepare 50 g of hydrochloric acid and ammonium chloride mixed so...

Embodiment 2

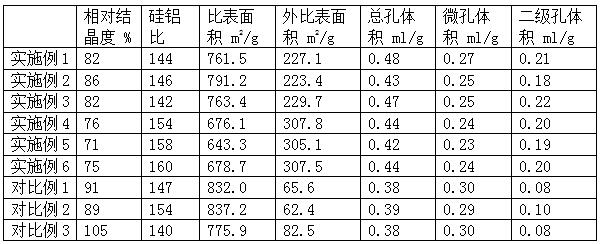

[0036] The molecular sieve was processed according to the steps described in Example 1, the difference being that the concentration of lye was reduced from 1mol / L to 0.75mol / L. The characterization results of the final samples are shown in Table 1.

Embodiment 3

[0038] The molecular sieve was treated according to the steps described in Example 2, the difference being that the alkali treatment time was increased from 1h to 2h. The characterization results of the final samples are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com