A kind of preparation method of hierarchical porous material

A multi-stage pore and solution technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as increasing auxiliary equipment, increasing the cost of synthesizing composite molecular sieves, and reducing the catalytic activity of heteropolyacids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

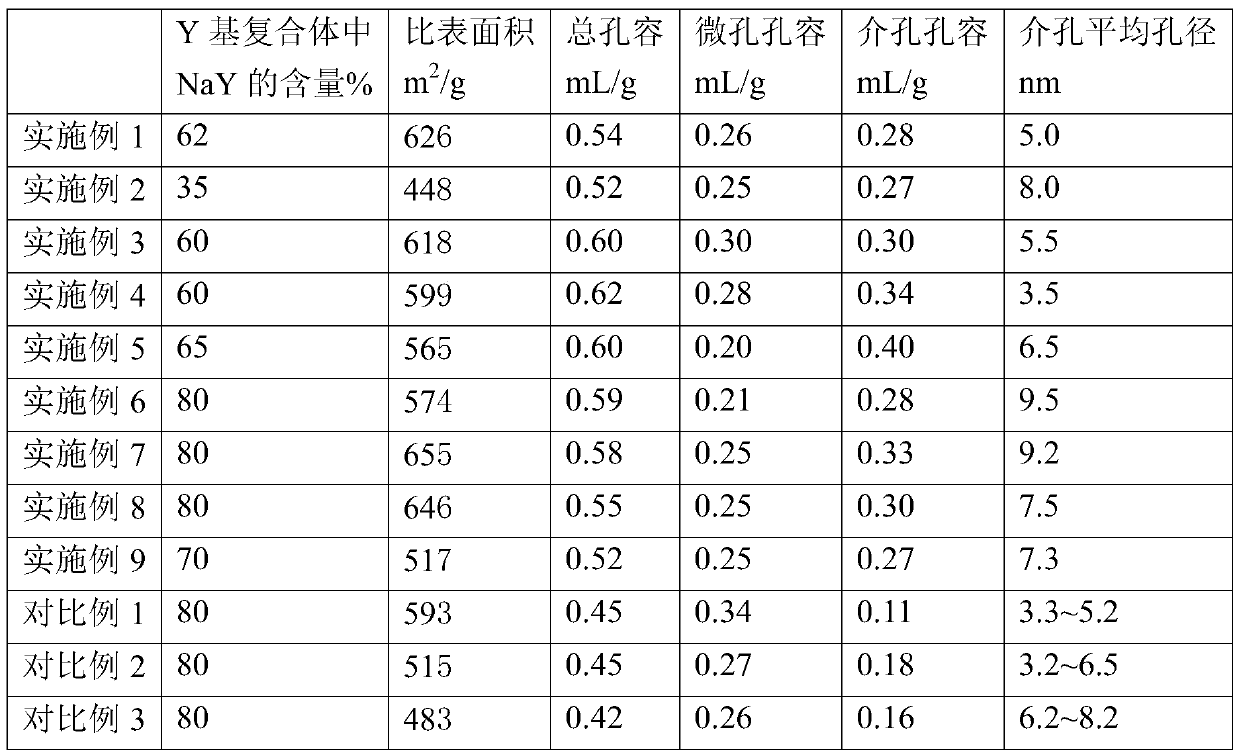

Examples

Embodiment 1

[0055] Embodiment 1: the synthesis of Y / SBA-6 / ZSM-12 / ASA hierarchical porous material

[0056] (1) Preparation of guiding agent: Take 24.7g of sodium hydroxide (Beijing Chemical Plant, analytically pure) and add it to 45.9g of water, stir until the sodium hydroxide is completely dissolved, then add 6.5g of sodium metaaluminate (researched by Shandong Aluminum Industry Co., Ltd. Institute, Industrial Products, Al 2 o 3 content 49.1wt%), stirred until the sodium metaaluminate was completely dissolved to obtain sodium metaaluminate solution A. 70g solution A and 100g water glass (Beijing Red Star Soda Soda Factory, SiO 2 Content 27.81wt%, Na 2 O content 8.74wt%) was poured into 65.5g of deionized water successively, stirred evenly, and aged at 30° C. for 22 hours to obtain the directing agent.

[0057] (2) Preparation of SBA-6 and ZSM-12 composite molecular sieve slurry: according to SBA-6 molecular sieve: ZSM-12 molecular sieve: aqueous solution ratio is 1:1:5, disperse the ...

Embodiment 2

[0061] Unless otherwise specified, the sources of each raw material are the same as in Example 1.

[0062] (1) Preparation of guiding agent: Take 24.7g of sodium hydroxide and add it to 45.9g of water, stir until the sodium hydroxide is completely dissolved, then add 6.5g of sodium metaaluminate, and stir until the sodium metaaluminate is completely dissolved to obtain metaaluminate Sodium solution A. Pour 70g of solution A and 100g of water glass into 65.5g of deionized water in sequence, stir evenly, and then statically age at 30°C for 22 hours to obtain the directing agent.

[0063] (2) Preparation of SBA-6 and ZSM-12 molecular sieve slurry: according to the ratio of SBA-6 molecular sieve: ZSM-12 molecular sieve: aqueous solution is 1:0.5:3, 2g of SBA-6 molecular sieve and 1g of ZSM-12 molecular sieve are dispersed in 6g of 6wt% scandium nitrate and 5wt% boric acid aqueous solution, heated to 70-80°C, stirred at constant temperature for 2 hours, to obtain SBA-6 and ZSM-12 ...

Embodiment 3

[0067] Unless otherwise specified, the sources of each raw material are the same as in Example 1.

[0068] (1) Preparation of guiding agent: Take 24.7g of sodium hydroxide and add it to 45.9g of water, stir until the sodium hydroxide is completely dissolved, then add 6.5g of sodium metaaluminate, and stir until the sodium metaaluminate is completely dissolved to obtain metaaluminate Sodium solution A. Pour 70g of solution A and 100g of water glass into 65.5g of deionized water in sequence, stir evenly, and then statically age at 30°C for 22 hours to obtain the directing agent.

[0069] (2) Preparation of SBA-6 and ZSM-12 composite molecular sieve slurry: according to SBA-6 molecular sieve: ZSM-12 molecular sieve: aqueous solution ratio is 1:0.75:4, the SBA-6 molecular sieve of 2g and the ZSM-12 molecular sieve of 1.5g Disperse in 8g of an aqueous solution of 7wt% scandium nitrate and 5wt% boric acid, heat to 70-80°C, and stir at a constant temperature for 2 hours to obtain SB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com