Modified molecular sieve and preparing method thereof

A molecular sieve and molecular sieve lattice technology are applied in the field of composite molecular sieves with TON and MFI structure modification and the preparation of the molecular sieves, which can solve the problems of affecting the physical and chemical properties of molecular sieves, high residual carbon content of molecular sieves, and difficult oxidation/decomposition, etc. The effect of stable properties, large pore volume and surface area, and high skeleton Si-Al ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In the organic solvent treatment process in the preparation method of the modified molecular sieve of the present invention, the organic solvent used can be selected from acetone, C 1 ~C 3 Alcohols and C 1 ~C 3 One or more of organic acids, preferably C 1 ~C 3 Alcohols, more preferably methanol. The treatment temperature can be from room temperature to 500°C, preferably from 80°C to 200°C, more preferably under reflux conditions in the solvent. The process pressure is the pressure to keep the solvent in the liquid phase, preferably an autogenous pressure. The treatment time is generally 0.5h-48h, preferably 1h-12h, more preferably 2h-4h. The amount of organic solvent used (ratio of liquid / solid mass) is generally 0.5-50, preferably 2-20, more preferably 5-10.

[0053] In the process of ion exchange in the method of the present invention, the solution used is to contain the compound solution that needs to introduce cations, preferably H + or / and NH 4 + A soluti...

Embodiment 1

[0062] A preparation process of a composite molecular sieve with two structures of TON and MFI is as follows:

[0063] (a) The preparation process of the gel is: 17.75 grams of 82% KOH, 37.8 grams of 1,8-octanediamine, 4 grams of AlCl 3 , 200 g SiO 2 30% silica sol, 2.9 g KF, 0.5 g SiO 2 / Al 2 o 3 TON structure molecular sieve (seed crystal, prepared in Comparative Example 1) with an average grain size of 44 and 0.6 microns and 577 grams of water were mixed together in a certain order, and after 20 minutes of vigorous stirring, a uniform gel-like mixture was obtained, and a condensed The molar composition of the glue is:

[0064] 1.3K 2 O / 3.00R / 0.15Al 2 o 3 / 10SiO 2 / 0.5KF / 400H 2 O+0.06%S

[0065] R=1,8-octanediamine, S is the seed crystal.

[0066] (b) Crystallization process: transfer the gel obtained in step (a) to a stainless steel autogenous pressure reactor, raise the reactor from room temperature to 165°C within two hours, stop heating after 48 hours of stati...

Embodiment 2

[0075] The preparation process of a kind of modified molecular sieve is:

[0076](1) Take 15 grams of the composite molecular sieve synthesized in Example 1, add it to a flask filled with 300 milliliters of methanol, and boil the solution at a heating rate of 1.5° C. / min under stirring conditions, reflux for 3 hours, and filter after finishing , washing and drying to obtain the molecular sieve from which the organic film plate agent has been removed.

[0077] (2) Same as step (2) of Comparative Example 2 to obtain dealuminated molecular sieves.

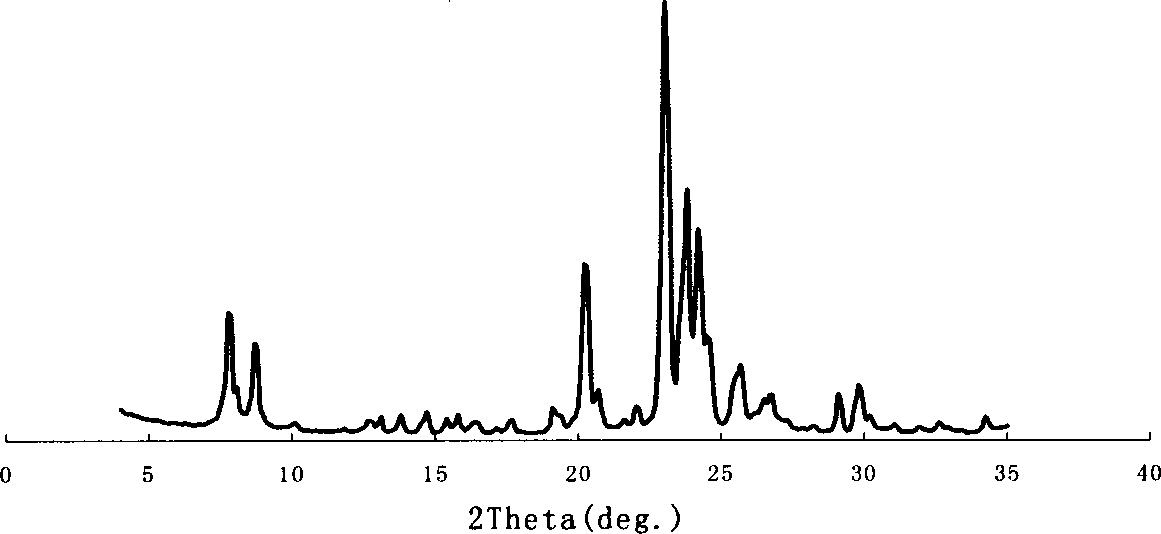

[0078] (3) With comparative example 2 step (3), obtain modified molecular sieve, numbering is E-2, and its XRD sees Figure 6 , the properties of the product are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com