Method for synthesizing Y type molecular sieve

A synthesis method and molecular sieve technology, which are applied in the directions of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of high molecular sieve cost, high production cost, pipeline blockage, etc., and achieve good thermal stability and Hydrothermal stability, superior catalyst coking, and reduced secondary cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of sodium metaaluminate solution: dissolve sodium hydroxide into deionized water, then add gibbsite evenly, react at 140°C for 5 hours, wait for the solution to cool to room temperature, and use it after filtration. Sodium metaaluminate solutions with different caustic ratios can be prepared according to experimental needs.

[0026] 1) Preparation of crystallization directing agent: 51.57g high alkalinity sodium metaaluminate solution (ρ=1330g / L, equivalent Al 2 o 3 Concentration is 40.2g / L, caustic ratio is 11.6) joins 89.75g water glass (SiO 2 The mass fraction is 19.68%, the modulus is 2.91), after stirring evenly, stir and age at room temperature for 24h, then add 10.91g of low alkalinity sodium metaaluminate solution (ρ=1400g / L, equivalent Al 2 o 3 The concentration is 192g / L, the caustic ratio is 2.5) and 4.54gH 2 O, after stirring evenly, transfer the mixture to a reaction kettle lined with polytetrafluoroethylene and rotate and age at ...

Embodiment 2

[0031] 1) The proportioning, raw materials and preparation method of the crystallization directing agent are the same as in Example 1;

[0032] 2) the proportioning, raw materials and preparation method of silica-alumina gel are the same as in Example 1;

[0033] 3) Add the prepared silica-alumina gel into a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it and rotate it at 80°C at 30r / min for 10h, then at 90°C at 30r / min for 20h , rapidly cooling the reaction kettle, the crystallized product was centrifuged and washed until the pH value of the filtrate was less than 9, and the filtered solid product was dried at 110°C.

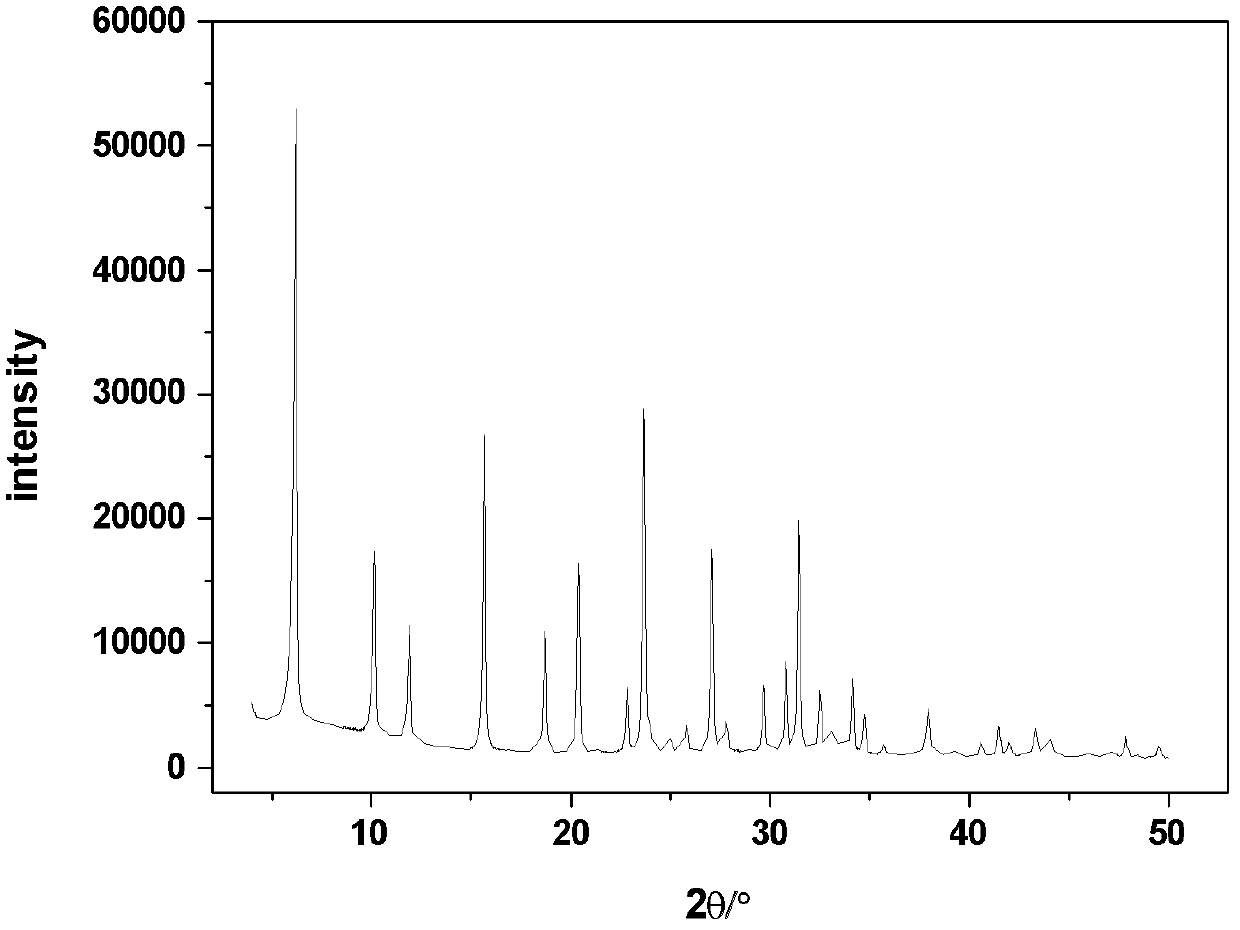

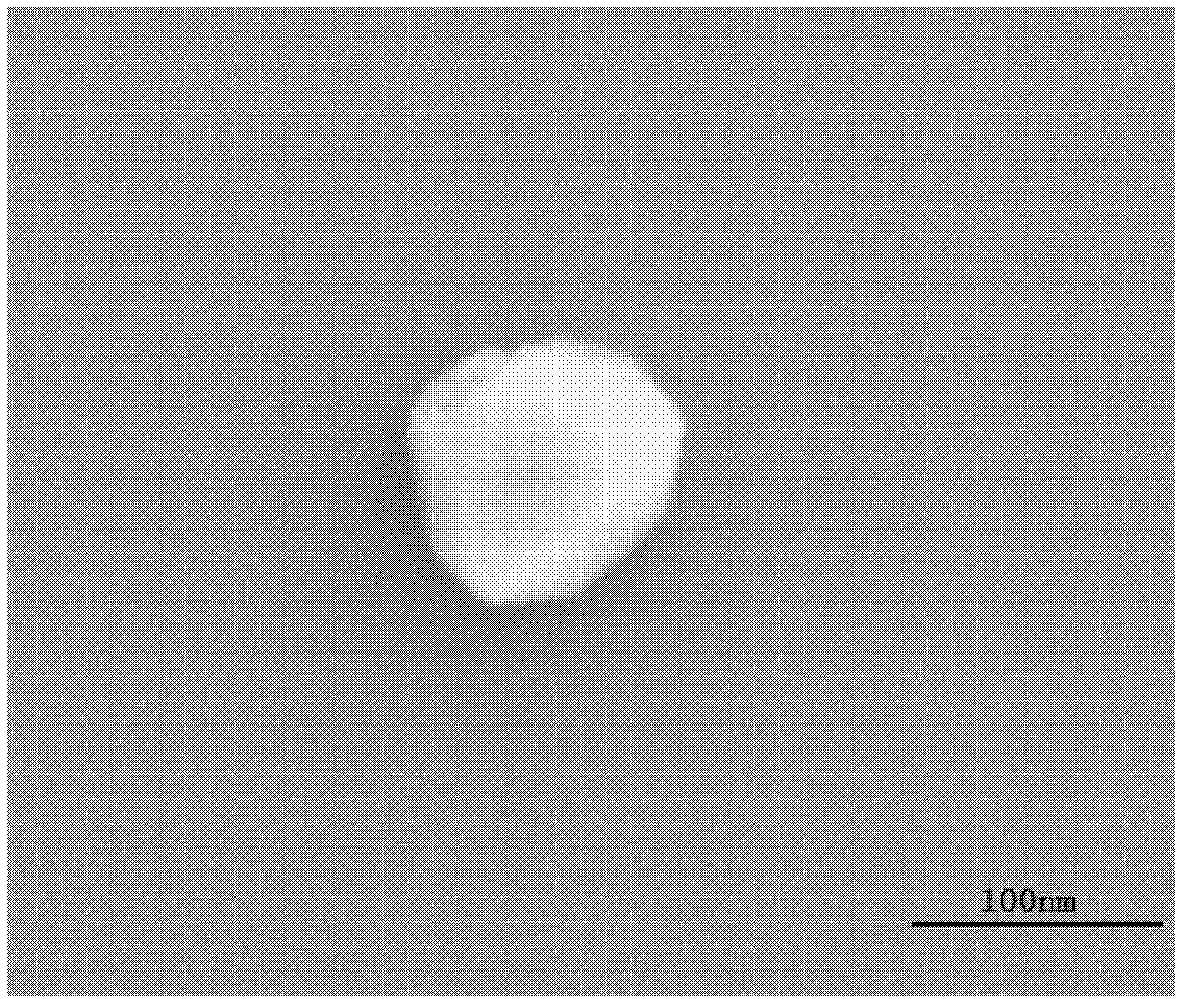

[0034] Physical and chemical characterization of the product: determine the relative crystallinity, average particle size and SiO of the product 2 / Al 2 o 3 Listed in Table 1. It can be seen from the XRD spectrum that the synthetic product is NaY molecular sieve.

Embodiment 3

[0036] 1) The proportioning, raw materials and preparation method of the crystallization directing agent are the same as in Example 1;

[0037] 2) According to the molar ratio is 3.3Na 2 O:Al 2 o 3 : 9.8SiO2 2 : 200H 2 O prepares silica-alumina gel, and all the other are identical with embodiment 1;

[0038] 3) Add the prepared silica-alumina gel into a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, and conduct static crystallization at 80°C for 10 hours, then statically crystallize at 100°C for 22 hours, cool the reaction kettle quickly, and crystallize The product was centrifuged and washed until the pH value of the filtrate was less than 9, and the solid product obtained by filtration was dried at 110°C.

[0039] Physical and chemical characterization of the product: determine the relative crystallinity, average particle size and SiO of the product 2 / Al 2 o 3 Listed in Table 1. It can be seen from the XRD spectrum that the synthesized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com