Synthetic method of load type molybdenum carbide catalyst

A molybdenum carbide catalytic material and synthesis method technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficulty in dispersing carbide particles, dangerous operation of Na metal, etc., and achieve good application and industry The effect of globalization prospects, low cost of process conditions, high product quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

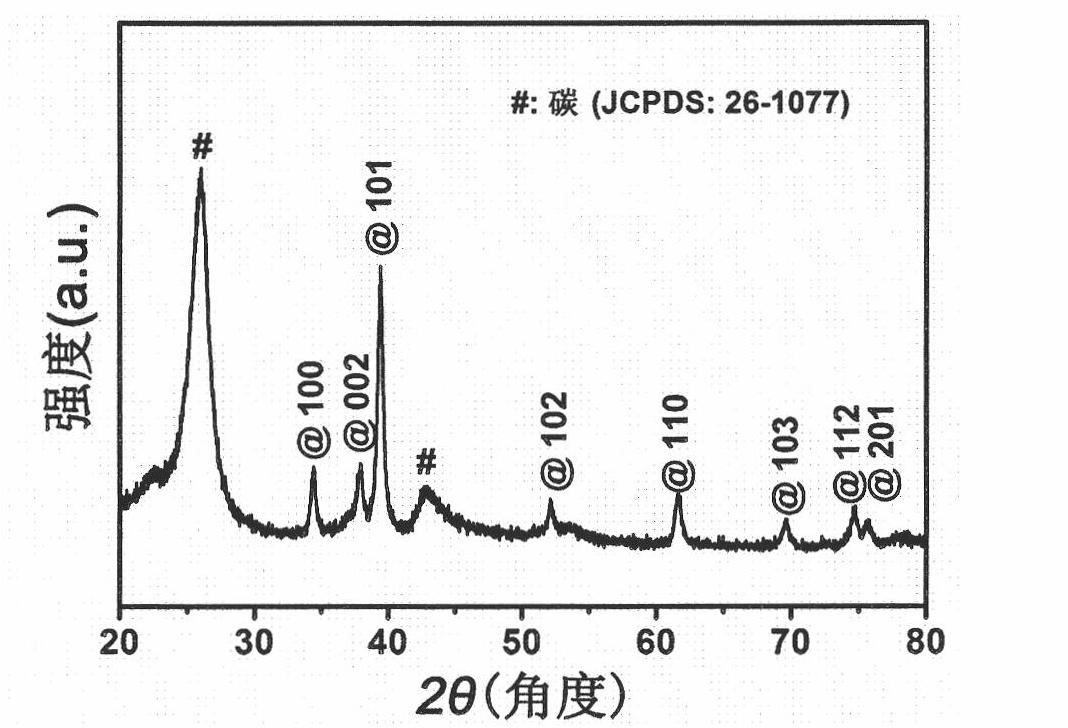

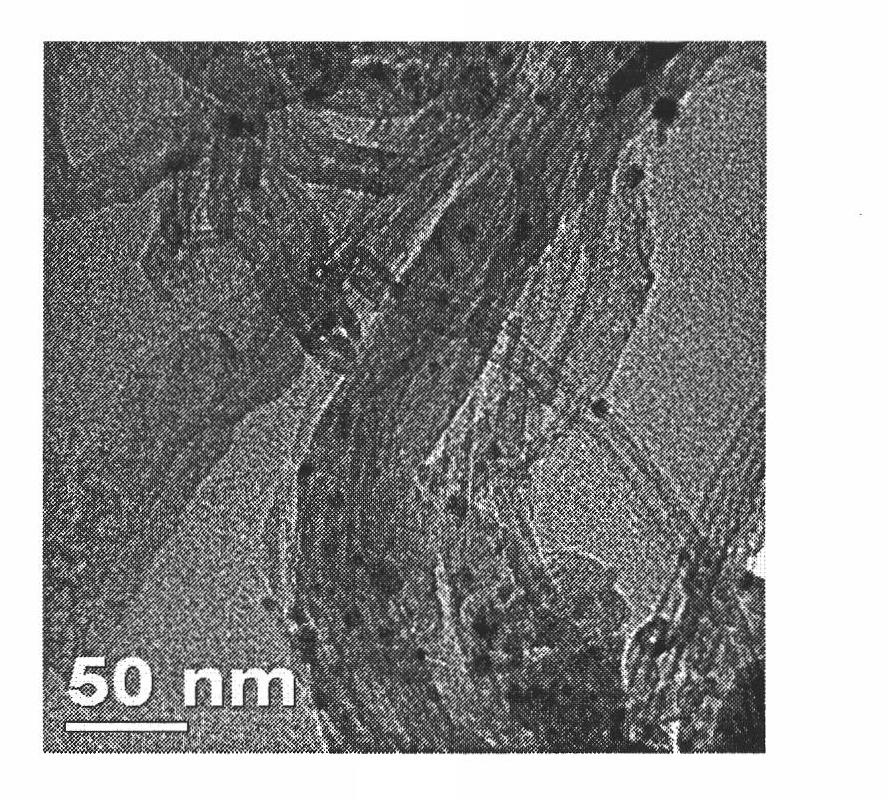

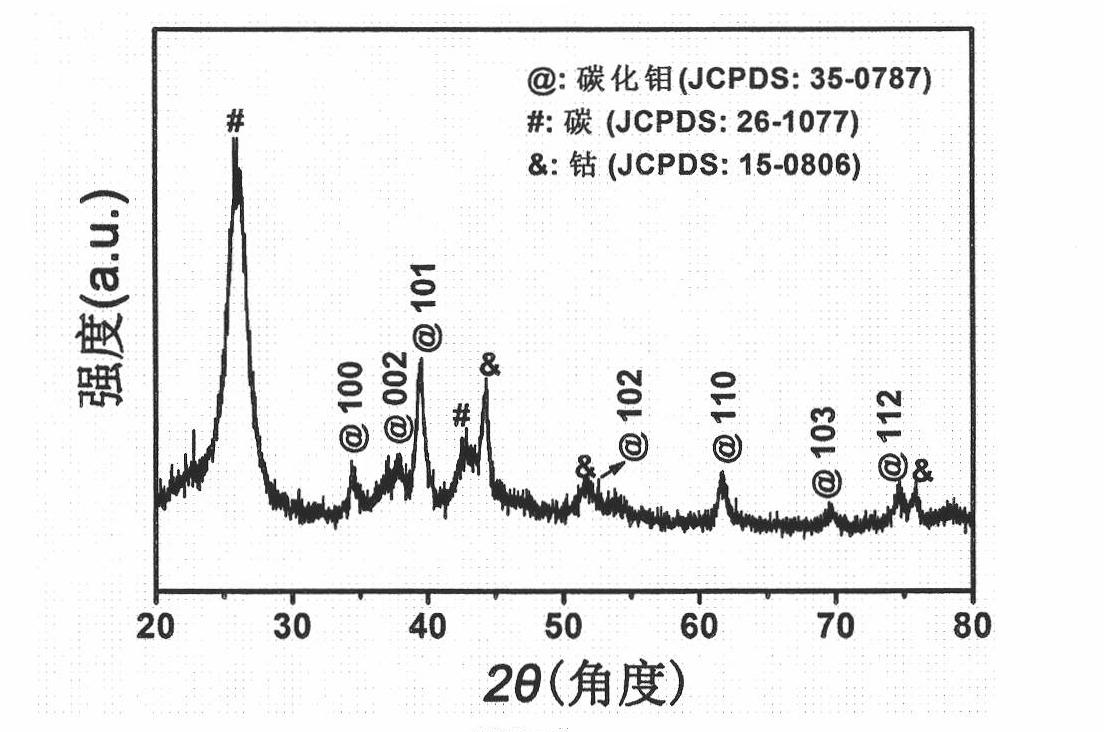

[0049] 6.0wt%Mo 2 C / CNT: 1.24g (NH 4 ) 6 Mo 7 o 24 4H 2 Dissolve O in 20 mL of distilled water, inject 1.90 g of aniline, and then add 1.0 mol / L hydrochloric acid dropwise until a white precipitate appears (pH 4-5). Transfer to an oil bath at 50° C., and react for 6 hours. The obtained product was washed several times with ethanol, filtered with suction, and dried at 50°C. Disperse 0.283g of the above precursor product in 40mLH 2 O and 40mL EtOH, ultrasonically dispersed for 10min, and then added 1.9g CNT under stirring. After stirring at room temperature for 12 hours, the above reactant was placed in an oven at 50° C. and dried overnight. The dried reactant was placed in a porcelain boat, moved into a tube furnace, and baked at 725 °C for 5 hours in an argon flow, and finally obtained 6.0wt% Mo 2 C / CNT catalyst A 1 .

Embodiment 2

[0051] Carry out experiment with the method similar to embodiment 1, but change molybdate concentration into 0.02mol / L (calculate in molybdenum atom), can obtain product A 2 .

Embodiment 3

[0053] Carry out experiment with the method similar to embodiment 1, but change molybdate concentration into 1.5mol / L (calculate in molybdenum atom), can obtain product A 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com